Copper Nickel CuNi2 Bar for Shipbuilding and Condenser Systems

Copper-nickel alloys have long been recognized as the gold standard for marine and industrial applications. Among them, CuNi2, CuNi6, and CuNi34 bars stand out for their specific balance of properties, each serving unique roles across industries. These alloys combine copper’s mechanical strength with nickel’s corrosion resistance, offering a range of options for both standard and demanding environments.

The CuNi2 6 34 bar series covers everything from electrical applications to large-scale marine systems. At DLX, we manufacture these bars with precision, ensuring compliance with international standards and guaranteeing performance in even the most challenging environments.

For more details, pls directly contact us.

The global shipbuilding and power generation sectors are undergoing rapid expansion. Increasing demand for reliable condenser systems, offshore structures, and marine vessels has pushed copper-nickel alloys to the forefront. With seawater corrosion being one of the main challenges, industries require materials that provide long-term durability without compromising strength.

CuNi alloys address this challenge effectively. CuNi2 is cost-effective and reliable for low-intensity applications, CuNi6 provides improved corrosion resistance for connectors and instrumentation, and CuNi34 excels in aggressive seawater conditions, making it ideal for high-performance systems. The ability to select from this range allows engineers to balance cost and performance while maintaining reliability.

-

Shipbuilding – Hull components, condenser tubes, and seawater piping systems.

-

Condenser Systems – CuNi34 is especially valuable for coastal and offshore power plants.

-

Electrical Industry – CuNi2 and CuNi6 bars are used in precision resistors and connectors.

-

Offshore Structures – Platforms, risers, and pipelines benefit from CuNi34’s resistance to seawater erosion.

-

Chemical Processing – Equipment exposed to moderately corrosive environments.

-

Desalination Plants – Seawater intake systems and evaporators.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

The rise in desalination projects, offshore wind energy, and naval expansion is boosting demand for copper-nickel alloys. Sustainability is another driver, as these alloys are recyclable and provide long service life, reducing environmental impact.

CuNi34, in particular, is becoming increasingly popular due to its superior performance in seawater environments. Meanwhile, CuNi2 and CuNi6 remain relevant for specialized roles where lower nickel content is sufficient. This tiered application ensures that the entire copper-nickel alloy family continues to grow in industrial importance.

Comparison Table

| Property | CuNi2 Bar | CuNi6 Bar | CuNi34 Bar |

|---|---|---|---|

| Nickel Content (%) | ~2 | ~6 | ~34 |

| Corrosion Resistance | Moderate | Good | Excellent |

| Mechanical Strength | High | High | Very High |

| Weldability | Excellent | Excellent | Good |

| Biofouling Resistance | Fair | Good | Outstanding |

| Typical Applications | Electrical components, resistors | Precision instruments, connectors | Shipbuilding, condensers, offshore platforms |

CuNi2 is best suited for electrical and industrial components where moderate resistance is sufficient. CuNi6 offers a balance of mechanical properties and corrosion resistance, ideal for connectors and precision equipment. CuNi34 delivers maximum protection against seawater corrosion, making it indispensable in shipbuilding and condenser systems.

This flexibility allows companies to select alloys tailored to their project’s specific needs without over-engineering or overspending.

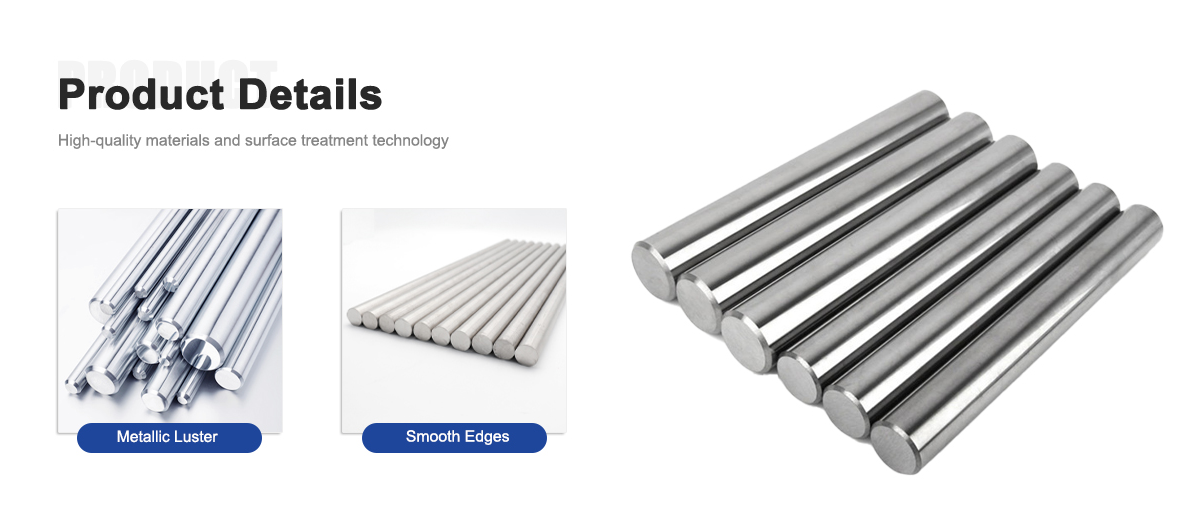

DLX stands as a trusted partner in the copper-nickel alloy market. Our CuNi2, CuNi6, and CuNi34 bars are manufactured under strict quality standards, ensuring consistent properties, smooth finishes, and reliable performance.

Our advantages include:

-

Wide Alloy Range – Offering multiple grades to meet different industrial needs.

-

Customization – Tailored dimensions and surface finishes.

-

Strict Quality Control – Each batch is tested for mechanical strength and corrosion resistance.

-

Technical Support – Engineering advice and material selection guidance.

-

Global Supply Chain – Reliable worldwide delivery for urgent projects.

These strengths make DLX the supplier of choice for industries requiring dependable copper-nickel solutions.

-

Shipbuilding Project in Europe – DLX supplied CuNi34 bars for condenser systems and seawater piping, ensuring reliable performance with minimal maintenance.

-

Power Plant in Asia – CuNi6 bars were used in connectors and instrumentation, supporting stable operations in high-humidity environments.

-

Electronics Manufacturer – CuNi2 bars provided precise and stable performance for resistors and specialized electrical components.

Global investments in marine, power, and desalination sectors will continue to drive demand for copper-nickel alloys. CuNi34 is expected to see the highest growth due to its critical role in seawater systems, while CuNi2 and CuNi6 will maintain steady demand in industrial and electrical sectors.

DLX is committed to staying at the forefront of this growth by continuously upgrading production technology and expanding supply capabilities. Our focus is on delivering both standard and customized solutions that meet the evolving needs of global industries.

Conclusion

The CuNi2, CuNi6, and CuNi34 alloy bars represent a spectrum of solutions for shipbuilding, condenser systems, and industrial applications. With their excellent corrosion resistance, mechanical strength, and adaptability, they remain vital to industries facing challenging environments.

DLX’s dedication to quality, customization, and reliable supply ensures that our customers can always count on our copper-nickel alloys to perform at the highest level. From shipbuilding to electronics, CuNi2 6 34 bars continue to prove their value in critical global industries.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the composition of CuNi2, CuNi6, and CuNi34 bars?

CuNi2 contains about 2% nickel, CuNi6 about 6% nickel, and CuNi34 about 34% nickel, with the balance being copper. -

Why are copper-nickel alloys used in shipbuilding?

They provide excellent resistance to seawater corrosion and biofouling, ensuring long service life in marine conditions. -

How do CuNi2, CuNi6, and CuNi34 differ in applications?

CuNi2 is used for electrical components, CuNi6 for connectors and instrumentation, and CuNi34 for high-performance marine and condenser systems. -

Are these bars weldable and machinable?

Yes, they have excellent weldability and good machinability, allowing easy fabrication. -

What industries use copper-nickel alloy bars?

Marine engineering, shipbuilding, power generation, chemical processing, and offshore energy. -

Can CuNi34 resist extreme seawater conditions?

Yes, CuNi34 provides outstanding resistance in the most aggressive seawater environments, making it ideal for condensers and offshore applications. -

Do these alloys reduce maintenance costs?

Yes, their durability and resistance to corrosion lower the need for frequent repairs and replacements. -

What standards apply to copper-nickel bars?

They are produced under ASTM, EN, and DIN standards to ensure consistency and quality.