High-Strength CuNi44 Bar for Precision Electrical Applications

Our CuNi44 bar is a powerhouse for precision electrical applications, designed to deliver top-tier performance where accuracy and strength are everything. This copper-nickel alloy, packed with 44% nickel and sometimes a touch of manganese, is our go-to for projects that demand reliability and precision in tough conditions.

Let’s talk about what makes CuNi44 bar so special. Its stable electrical resistivity—around 5-6% IACS—is perfect for precision resistors and thermocouples, ensuring consistent performance in electronics and aerospace systems. Whether you’re building control circuits or temperature sensors, this bar delivers the accuracy you need. Plus, it’s got high thermal stability, handling up to 500°C, so it’s ready for high-temperature environments like industrial electronics or energy systems.

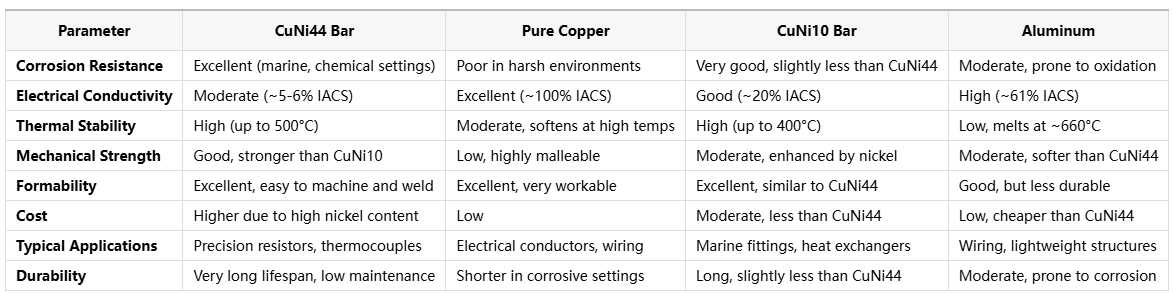

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

Strength and durability are where CuNi44 really flexes. The high nickel content gives it excellent corrosion resistance, making it a champ in harsh settings like chemical plants or coastal facilities. It laughs off corrosion where other materials would fail, which means less maintenance and longer-lasting components. That’s a big win for industries where downtime is a dealbreaker.

This bar is also a dream to work with. Its excellent formability lets you machine, weld, or shape it into whatever your project calls for. Need a custom size or profile for a specific electrical component? We can tweak the specs to fit your needs, making it easy to integrate into your designs. It’s a favorite for engineers working on bespoke solutions in high-tech sectors.

The industry’s trending toward materials that combine precision, durability, and sustainability, and CuNi44 bar nails it. It’s recyclable, which is awesome for eco-friendly projects, and its long lifespan means fewer replacements, cutting down on waste. With electronics and renewable energy sectors booming—think IoT devices and smart grids—CuNi44’s precision and reliability are in high demand.

Compared to other materials, CuNi44 stands tall. Pure copper’s great for conductivity but can’t handle corrosion or heat like CuNi44. CuNi10 offers better conductivity but less strength and corrosion resistance, making CuNi44 the better pick for precision tasks. Aluminum’s lightweight and conductive but lacks the durability and thermal stability of CuNi44. This bar is the perfect balance for high-stakes applications.

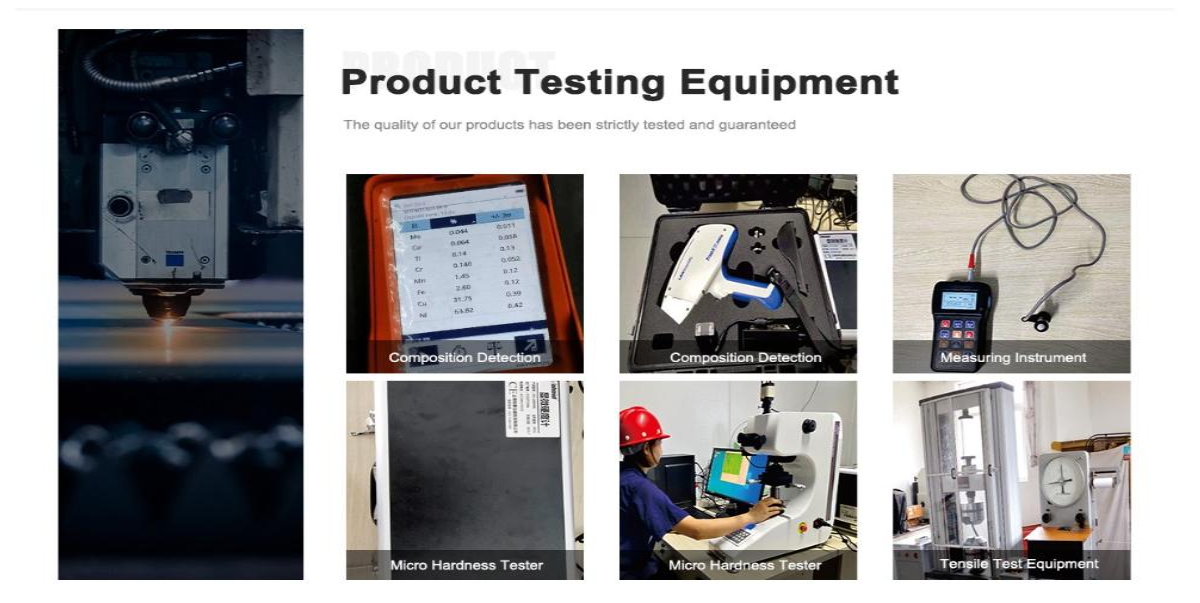

We craft our CuNi44 bar to meet strict standards like ISO 9001, so you’re getting quality you can trust every time. Whether you’re designing cutting-edge electronics or robust thermocouple systems, this bar’s ready to perform. Got a unique spec in mind? Let us know, and we’ll make it happen.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is CuNi44 bar made of?

It’s a copper-nickel alloy with 44% nickel, sometimes with manganese for improved stability and corrosion resistance.What are the primary uses for CuNi44 bar?

It’s used in precision resistors, thermocouples, electrical components, and high-performance parts in electronics and aerospace.How does CuNi44 bar perform in precision applications?

Its stable electrical resistivity ensures accurate performance in resistors and thermocouples, perfect for precision systems.Is CuNi44 bar corrosion-resistant?

Absolutely, its high nickel content makes it excellent against corrosion in chemical, marine, and industrial environments.Can CuNi44 bar handle high temperatures?

Yes, it’s stable up to 500°C, ideal for high-temperature electrical and thermocouple applications.Is CuNi44 bar cost-effective?

It’s pricier than lower-nickel alloys, but its durability and precision performance make it worth it for critical applications.Can CuNi44 bar be customized?

Totally! We can tailor dimensions, forms, or specs to meet your specific electrical or mechanical requirements.Is CuNi44 bar environmentally friendly?

It’s recyclable, supporting sustainable practices, and its long lifespan reduces waste from frequent replacements.