Precision Copper Nickel CuNi1 Bar for Electrical Components

In industries where precision, stability, and durability are critical, copper-nickel alloys such as CuNi1 , CuNi2 , and CuNi6 round bars have proven their reliability. These alloys are specifically designed for electrical and electronic components, offering a unique balance between electrical conductivity, corrosion resistance, and thermal stability.

At DLX, we specialize in producing precision copper-nickel alloy bars that meet the exacting requirements of modern industries. Our CuNi1, CuNi2, and CuNi6 products are engineered to deliver consistent performance, whether used in sensitive electronic circuits or marine-based electrical systems.

For more details, pls directly contact us.

The global demand for copper-nickel alloys in electrical applications continues to grow due to the expansion of the electronics industry and the increasing need for reliable materials in telecommunications, power generation, and automation. These alloys provide consistent performance under both normal and harsh conditions, making them indispensable in modern infrastructure.

While pure copper offers excellent conductivity, it falls short in resistance to corrosion and mechanical wear. On the other hand, adding small amounts of nickel—as in CuNi1, CuNi2, and CuNi6—enhances durability without significantly compromising electrical conductivity. This balance is one of the reasons these alloys are favored across multiple sectors.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

CuNi30 |

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

-

Connectors and Terminals – Used in electrical assemblies where conductivity and stability are essential.

-

Resistors and Heating Elements – CuNi2 and CuNi6 bars provide consistent resistance values, ideal for control systems.

-

Telecommunication Equipment – Ensures reliable signal transmission in challenging environments.

-

Marine Electrical Systems – CuNi6 is particularly effective due to its superior corrosion resistance.

-

Precision Instruments – CuNi1 and CuNi2 are commonly used in measurement devices requiring accuracy.

-

Power Distribution Systems – Reliable components for switchgear, transformers, and conductors.

As industries embrace smart technologies and renewable energy, the demand for precise, stable, and corrosion-resistant alloys is rapidly increasing. With electric vehicles, smart grids, and renewable power systems becoming mainstream, copper-nickel alloys are playing a more significant role in ensuring durability and reliability in critical electrical components.

Additionally, the miniaturization of electronics requires materials that can be machined into fine, precise shapes without sacrificing performance. CuNi1, CuNi2, and CuNi6 alloys align perfectly with these demands, offering machinability alongside durability.

Comparison Table

| Property | CuNi1 Bar | CuNi2 Bar | CuNi6 Bar |

|---|---|---|---|

| Nickel Content (%) | ~1 | ~2 | ~6 |

| Electrical Conductivity | Very High | High | Moderate |

| Corrosion Resistance | Good | Very Good | Excellent |

| Oxidation Resistance | Strong | Strong | Strong |

| Mechanical Strength | Moderate | Good | High |

| Typical Applications | Connectors, precision electronics | Electrical components, resistors | Marine, electronics, instrumentation |

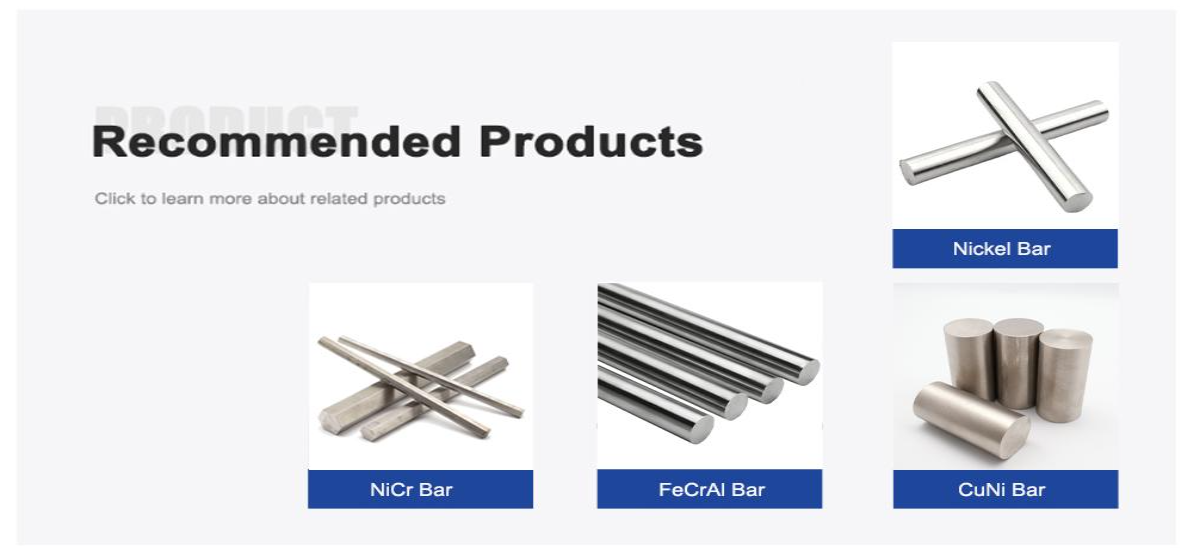

Each alloy serves unique roles. CuNi1, with its low nickel content, maintains very high conductivity, making it suitable for connectors and signal components. CuNi2 offers a balance of conductivity and resistance, ideal for resistors and general electrical parts. CuNi6, with higher nickel content, stands out in harsh environments like marine and industrial systems, where resistance to corrosion and wear is crucial.

At DLX, we are committed to providing copper-nickel alloys that combine precision, quality, and consistency. Our CuNi1, CuNi2, and CuNi6 bars are manufactured under strict standards to guarantee uniform composition and performance.

Key advantages of choosing DLX include:

-

Diverse Product Range – From low-nickel CuNi1 to higher-performance CuNi6, we cover the full spectrum of electrical alloys.

-

Custom Solutions – Tailored dimensions, tolerances, and finishes to meet exact customer specifications.

-

Strict Quality Control – Every batch undergoes testing for conductivity, corrosion resistance, and mechanical properties.

-

Technical Expertise – Our team provides support in selecting the right alloy for each application.

-

Reliable Global Supply – With a robust logistics network, we ensure timely delivery worldwide.

-

Electronics Manufacturer in Europe – DLX supplied CuNi1 bars for connectors in precision instruments, ensuring high conductivity and stability.

-

Telecommunications Project in Asia – CuNi2 bars were chosen for resistive components, providing consistent signal performance under varying conditions.

-

Marine Electrical System in the Middle East – CuNi6 bars were integrated into offshore power distribution systems, offering long-term corrosion resistance.

The demand for copper-nickel alloys in electrical applications is expected to rise steadily as technology evolves. With increasing requirements for precision, miniaturization, and durability, alloys like CuNi1, CuNi2, and CuNi6 will continue to play a vital role in global industries.

DLX is strategically positioned to meet this demand by expanding production capabilities, enhancing research, and continuously innovating to support industry requirements.

Conclusion

The CuNi1, CuNi2, and CuNi6 alloy bars represent the perfect blend of conductivity, corrosion resistance, and durability. From electrical components and resistors to marine systems and telecommunications, these alloys provide reliable solutions across a wide range of industries.

With DLX as a partner, customers gain more than just a supplier—they gain a trusted ally dedicated to delivering high-performance copper-nickel alloys with precision and consistency. Our focus on quality, customization, and global support makes DLX the preferred choice for industries relying on CuNi1, CuNi2, and CuNi6 alloy bars.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the main composition of CuNi1, CuNi2, and CuNi6 bars?

They are copper-nickel alloys with nickel contents of approximately 1%, 2%, and 6%, respectively. -

Why are these alloys suitable for electrical components?

They provide excellent electrical resistivity, thermal stability, and corrosion resistance. -

How does CuNi1 differ from CuNi6?

CuNi1 has lower nickel content, offering higher conductivity, while CuNi6 provides better corrosion resistance and mechanical strength. -

Are CuNi1, CuNi2, and CuNi6 easy to machine?

Yes, they have good machinability and can be formed into precise shapes required in electrical applications. -

Do these alloys resist oxidation?

Yes, they exhibit strong resistance to oxidation even under elevated temperatures. -

Can they be used in marine or humid environments?

Yes, the corrosion resistance makes them suitable for such applications. -

Which industries benefit the most from CuNi1, CuNi2, and CuNi6 bars?

Electrical, electronics, telecommunications, precision instruments, and marine industries. -

Do these alloys comply with international standards?

Yes, they meet ASTM, DIN, and EN specifications for quality and performance.