High-Strength Copper Nickel Alloy CuNi14 Bar for Marine Engineering

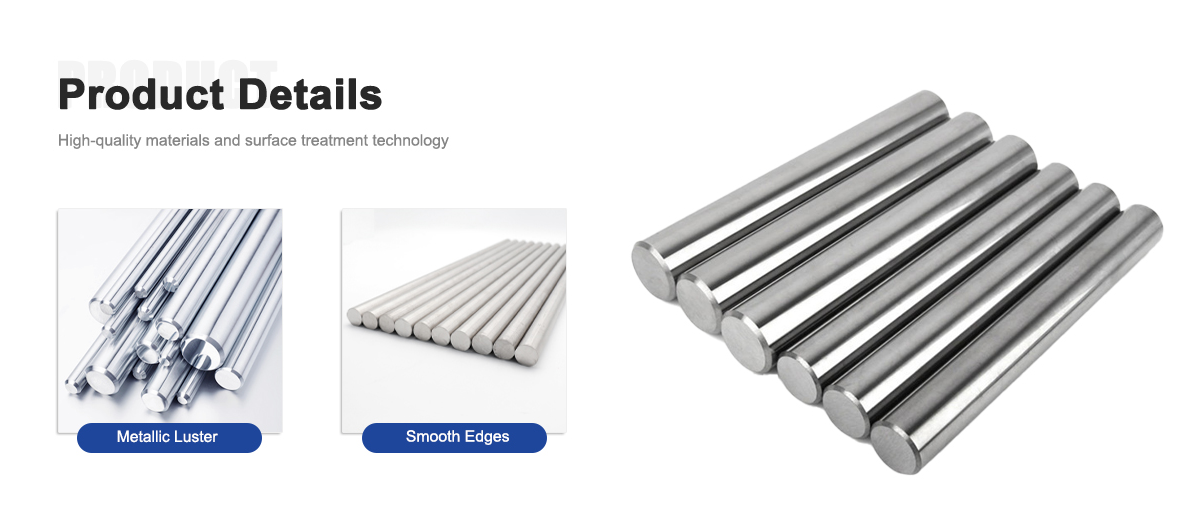

The copper-nickel alloy CuNi1 4 bar is a high-strength, corrosion-resistant material designed for performance in demanding marine engineering and industrial environments. Containing around 14% nickel, it provides an optimal balance between durability, resistance to seawater, and mechanical integrity. Its ability to perform consistently in harsh conditions makes it a preferred choice for engineers and designers in industries where reliability is paramount.

At DLX, we specialize in manufacturing and supplying premium CuNi14 bars that meet stringent international standards. By leveraging advanced production technology, we ensure uniformity, structural stability, and long-term performance for every piece of material we deliver.

For more details, pls directly contact us.

Marine engineering faces unique challenges, particularly exposure to seawater corrosion, stress cracking, and biofouling. Traditional materials like carbon steels and low-grade stainless steels often fail in these conditions, leading to costly repairs and replacements. This is where copper-nickel alloys, specifically CuNi14, come into play.

In recent years, the demand for copper-nickel alloys has increased significantly due to global growth in desalination plants, offshore oil exploration, and expansion of naval and commercial shipbuilding. Countries investing in renewable energy through offshore wind farms also rely on corrosion-resistant alloys like CuNi14 for piping, connectors, and supporting structures exposed to seawater.

Compared to alternative alloys, CuNi14 offers an attractive balance of cost, performance, and availability. It fills the gap between lower nickel grades (like CuNi8 ) and more expensive, high-nickel options (like CuNi34). This positioning makes it a smart choice for both large-scale industrial projects and specialized marine applications.

Applications of CuNi14 Bars

-

Shipbuilding – Used in seawater piping systems, condensers, and heat exchangers to ensure reliable long-term service.

-

Marine Engineering – Ideal for offshore platforms, risers, and underwater structures due to resistance to seawater and biofouling.

-

Desalination Plants – Essential for piping and heat exchangers where seawater contact is constant.

-

Power Generation – Applied in cooling water circuits, particularly in coastal power plants.

-

Aerospace and Automotive – In specialized cases, it’s used for components requiring corrosion resistance combined with structural integrity.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

|

CuNi2 |

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

CuNi6 |

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

CuNi8 |

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

CuNi10 |

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

CuNi14 |

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

|

CuNi34 |

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

The global trend toward sustainable energy and infrastructure is driving steady growth in copper-nickel alloy usage. With an increased emphasis on reducing maintenance costs and ensuring durability, industries are turning toward long-lasting materials like CuNi14. Marine environments are especially unforgiving, and this alloy provides a dependable solution, reducing downtime and extending equipment life cycles.

Moreover, international naval modernization programs are boosting demand for seawater-resistant materials. CuNi14, with its excellent combination of cost-effectiveness and durability, continues to gain traction in these sectors.

Comparison Table

| Property | CuNi14 Bar | CuNi19 Bar | CuNi23 Bar |

|---|---|---|---|

| Nickel Content (%) | ~14 | ~19 | ~23 |

| Corrosion Resistance | Excellent | Superior | Exceptional |

| Mechanical Strength | High | Very High | Very High |

| Thermal Stability | Strong | Strong | Strong |

| Seawater Resistance | Excellent | Excellent | Excellent |

| Cost Efficiency | Balanced | Higher | Highest |

| Typical Applications | Marine engineering, piping | Power plants, condensers | Offshore structures, advanced shipbuilding |

While stainless steels and other nickel alloys are sometimes considered for similar applications, they often fall short in terms of resistance to biofouling and long-term seawater exposure. Stainless steels, for instance, can suffer from localized corrosion and require additional maintenance. CuNi14 outperforms them by offering natural resistance without the need for coatings or extensive upkeep.

At DLX, we set ourselves apart in the market by focusing on consistency, quality, and customer-driven solutions. Unlike other suppliers, we maintain strict quality control at every stage of production, from raw material sourcing to final inspection. Our advanced production facilities allow us to deliver CuNi14 bars with tight dimensional tolerances and excellent surface finish, ensuring they integrate seamlessly into customer projects.

We also provide customization to meet the specific requirements of our clients, whether in terms of size, shape, or finishing. Our engineering team works closely with customers to design and deliver solutions optimized for their applications. This consultative approach not only ensures satisfaction but also establishes long-term trust and collaboration.

Another key advantage of working with DLX is our global logistics network. We ensure timely delivery across international markets, backed by efficient supply chain management. In industries where project deadlines are critical, this reliability sets us apart.

Applications in Case Studies

-

In a large-scale desalination project, DLX supplied CuNi14 bars that were used in seawater piping systems. The alloy’s resistance to scaling and corrosion minimized downtime, significantly reducing operational costs.

-

For an offshore oil platform, our CuNi14 bars were chosen due to their ability to withstand aggressive seawater conditions and maintain mechanical strength under stress, ensuring long-term reliability.

The demand for CuNi14 is expected to rise in the coming years, especially with the global push toward renewable energy infrastructure and sustainable water solutions. As desalination plants expand and offshore energy projects multiply, materials like CuNi14 will remain indispensable.

DLX is committed to staying at the forefront of this growth by investing in research and production technologies, ensuring that our customers continue to benefit from the latest advancements in copper-nickel alloy solutions.

Conclusion

The CuNi14 bar represents a reliable, high-performance choice for industries where seawater exposure and corrosion resistance are critical. With its balance of strength, durability, and cost-effectiveness, it has become an essential material in marine engineering and beyond.

DLX’s expertise, quality focus, and customer-centric approach make us the trusted partner for delivering CuNi14 bars to projects worldwide. Our commitment to innovation and reliability ensures that our clients can confidently tackle their toughest engineering challenges with materials built to last.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the composition of CuNi14 alloy?

CuNi14 alloy is primarily composed of copper and nickel, with approximately 14% nickel and trace elements that enhance mechanical strength and corrosion resistance. -

What industries commonly use CuNi14 bars?

They are widely used in marine engineering, shipbuilding, desalination plants, heat exchangers, and offshore oil and gas systems. -

Why is CuNi14 bar suitable for marine applications?

It offers superior resistance to seawater corrosion, biofouling, and stress cracking, making it reliable in aggressive marine environments. -

Can CuNi14 bars be welded?

Yes, the alloy has good weldability and can be fabricated using standard welding techniques without compromising corrosion resistance. -

What are the mechanical properties of CuNi14 bar?

It provides excellent tensile strength, high ductility, and resistance to erosion, making it ideal for demanding structural and piping applications. -

How does CuNi14 compare to other copper-nickel alloys?

CuNi14 balances strength and corrosion resistance better than lower nickel grades while being more cost-effective than higher nickel grades. -

Is CuNi14 bar resistant to biofouling?

Yes, it naturally resists biofouling in seawater, reducing maintenance costs in marine installations. -

What standards cover CuNi14 bars?

They are typically manufactured under international standards such as ASTM, EN, and DIN specifications for copper-nickel alloys.