Precision CuNi20 Bar for Advanced Electrical Conductors

Our CuNi20 bar is a rock-solid choice for advanced electrical conductors, delivering the perfect mix of conductivity, durability, and precision. This copper-nickel alloy, with 20% nickel and sometimes a bit of manganese or iron, is our go-to for projects where reliable electrical performance is a must.

Let’s break down why CuNi20 bar is such a standout. Its electrical conductivity—around 15% IACS—hits a sweet spot for precision conductors, resistors, and even thermocouples. It’s stable and consistent, making it ideal for electronics, aerospace, and energy systems where accuracy is everything. Plus, it handles temperatures up to 450°C, so it’s great for applications that need to stay cool under heat, like control circuits or sensor components.

Corrosion resistance is another big win. The 20% nickel content gives this bar serious staying power in tough environments—think humid factories, chemical plants, or even coastal setups. It resists rust where pure copper would fail, which means your conductors last longer with less maintenance. That’s a huge plus for industries where downtime is a dealbreaker.

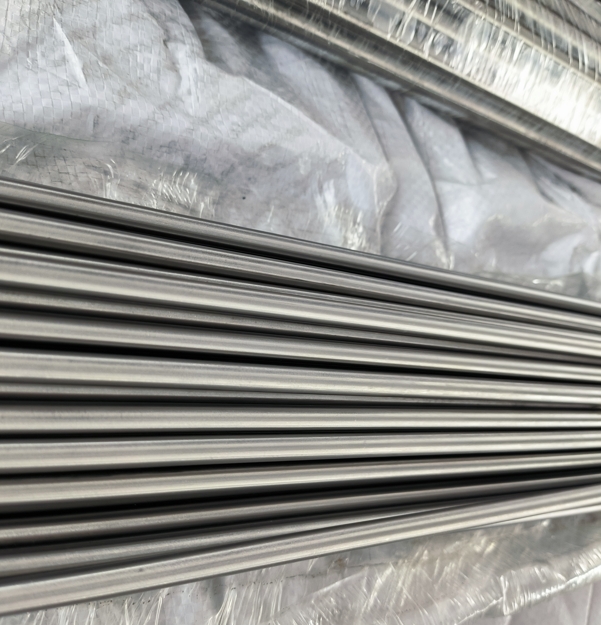

This bar is a breeze to work with. Its excellent formability lets you machine, weld, or shape it into whatever your project needs—bars, rods, or custom profiles. Need a specific size for a unique conductor design? We can customize it to fit your specs, making production smooth and efficient.

The industry’s pushing for materials that balance performance with sustainability, and CuNi20 bar nails it. It’s recyclable, which is awesome for eco-friendly projects, and its durability means fewer replacements and less waste. With electronics and renewable energy sectors booming—think smart grids and IoT devices—CuNi20’s blend of conductivity and toughness is in high demand. It’s perfect for the shift toward energy-efficient, long-lasting electrical systems.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 | |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

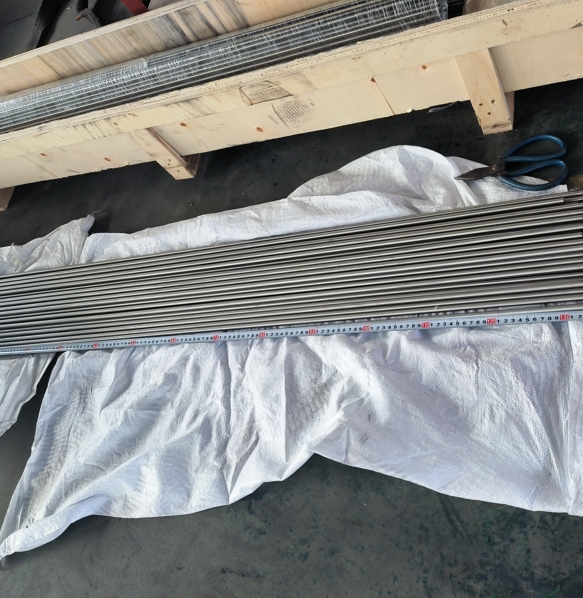

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

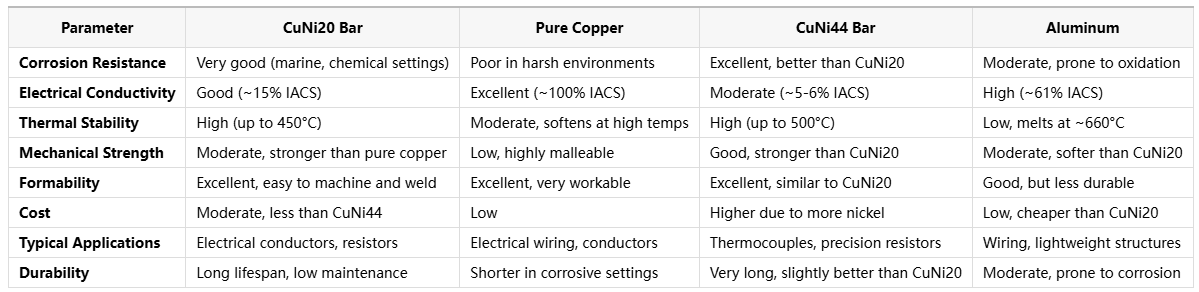

Compared to other materials, CuNi20 holds its own. Pure copper’s a conductivity king but corrodes fast in harsh conditions. CuNi44 has better corrosion resistance but lower conductivity, making CuNi20 a cost-effective middle ground. Aluminum’s lightweight and conductive but lacks CuNi20’s durability and thermal stability. This bar is the perfect fit for advanced electrical applications.

We craft our CuNi20 bar to meet strict standards like ISO 9001, so you’re getting quality you can trust every time. Whether you’re building next-gen electronics or robust energy systems, this bar’s ready to perform. Got a custom design in mind? Let us know, and we’ll make it happen.

Comparison Parameters Table

About Us:

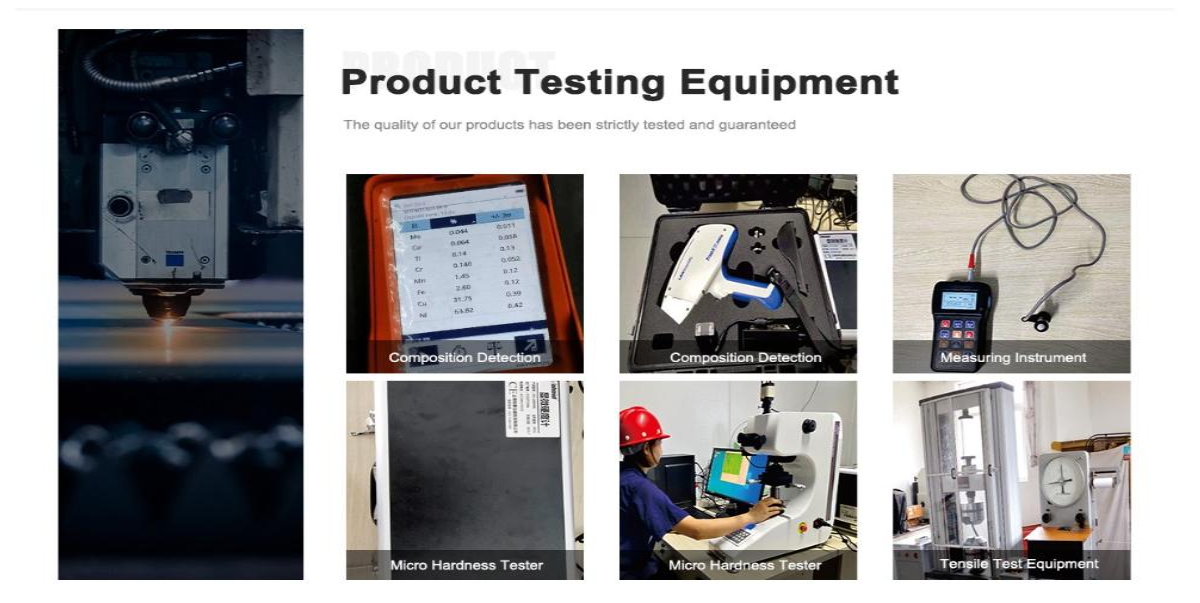

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is CuNi20 bar made of?

It’s a copper-nickel alloy with 20% nickel, sometimes with small amounts of manganese or iron for enhanced properties.What are the main uses for CuNi20 bar?

It’s used in advanced electrical conductors, resistors, thermocouples, and components in electronics, aerospace, and energy sectors.How does CuNi20 bar perform in electrical applications?

It offers solid electrical conductivity (~15% IACS) and stable resistivity, perfect for precision conductors and resistors.Is CuNi20 bar corrosion-resistant?

Very much so—its nickel content makes it great at resisting corrosion in humid, chemical, or marine environments.Can CuNi20 bar handle high temperatures?

Yep, it’s stable up to about 450°C, suitable for electrical conductors and low-to-mid-temperature systems.Is CuNi20 bar cost-effective?

It’s more expensive than pure copper, but its balance of conductivity and durability makes it a smart choice for precision applications.Can CuNi20 bar be customized?

Absolutely! We can adjust dimensions or forms (bar, rod, plate) to meet your specific electrical conductor needs.Is CuNi20 bar environmentally friendly?

It’s recyclable, supporting sustainable practices, and its long lifespan reduces waste from frequent replacements.