Global CuNi Alloy Bar Manufacturer Expands Production for Energy Projects

CuNi Alloy bars—commonly containing copper with controlled nickel percentages—are widely used across energy, marine, and high-corrosion environments. Their stability under heat, resistance to seawater, low magnetic permeability, and reliable mechanical strength make them a top choice for major engineering projects. CuNi alloys also maintain consistent electrical and thermal conductivity, which allows them to serve in both structural and functional roles.

Key characteristics include:

Strong corrosion resistance in marine water and brine environments

High durability against stress corrosion and erosion

Good thermal stability

Predictable electrical resistivity

Excellent weldability and formability

Long service life in high-humidity and high-salinity conditions

DLX alloy bar products are produced through vacuum melting and precision hot/cold working to ensure tight tolerances, uniform grain structure, and stable performance across large project installations.

Applications of CuNi Alloy Bars

CuNi alloy bars remain crucial across multiple global sectors:

Energy infrastructure (power plants, offshore systems, heat exchangers)

Shipbuilding and marine engineering

Desalination systems

Oil & gas pipelines and instrumentation

Cryogenic equipment

Chemical processing and fluid control

Industrial valves and pump components

High-temperature resistance parts

Their combination of thermal and corrosion resistance makes CuNi alloys suitable for both high-stress mechanical components and highly corrosive liquid systems.

Industry Trends Driving Demand

Several major trends are pushing global demand for CuNi alloy bars:

Acceleration of offshore energy projects (wind, oil, gas, hydrogen)

Expansion of desalination plants in water-scarce regions

Upgrades of thermal power stations and heat-exchange systems

Growth in shipbuilding and marine vessel modernization

Higher requirements for corrosion-resistant materials in harsh environments

Increased infrastructure investments across developing markets

Rising global demand for low-maintenance, long-service-life materials

These trends have created a need for stable, large-scale supply of CuNi alloy bar products—driving the expansion of manufacturers like DLX Alloy.

Comparison Table: CuNi Alloy Bar vs Other Industrial Copper Alloys

| Property | CuNi Alloy Bar | High-Purity Copper Bar | Brass Bar |

|---|---|---|---|

| Corrosion Resistance | Excellent (especially seawater) | Low–Medium | Medium |

| Mechanical Strength | High | Medium | Medium–High |

| Heat Resistance | High | Medium | Medium |

| Electrical Conductivity | Medium | Very high | Medium |

| Weldability | Excellent | Good | Good |

| Ideal Applications | Energy systems, marine engineering, desalination | Electrical components | General machinery |

News Article: Global CuNi Alloy Bar Manufacturer Expands Production for Energy Projects

Market Overview

The global energy market is shifting toward more specialized materials that can handle extreme conditions—whether it's offshore wind installation, high-salinity desalination plants, or long-term heat-exchange systems in industrial facilities. This shift has created a surge in demand for CuNi alloy bars, a category known for outstanding corrosion resistance, long service life, and strong thermal performance.

DLX Alloy has been part of this momentum for years, supplying CuNi materials to companies involved in power systems, marine installations, and water-treatment engineering. As global demand accelerates, we’ve taken steps to significantly expand our capability to deliver CuNi alloy bars at industrial scale.

DLX Alloy Announces Expanded Production Capacity

In response to large-volume orders for energy and marine projects, DLX Alloy has completed a major expansion of its CuNi alloy bar production line. The upgrade increases melting capacity, improves rolling and drawing efficiency, and strengthens real-time quality control. This upgrade allows us to support both high-volume project delivery and customized specifications for specialized engineering requirements.

The new production capability is designed to deliver uniform, high-purity CuNi alloy bars with precise mechanical properties. Customers working on offshore platforms, desalination systems, and industrial thermal plants can now receive higher-volume shipments with shorter lead times.

Why CuNi Alloys Are Becoming Essential in Modern Energy Engineering

CuNi alloys have become one of the most dependable materials for harsh environments. As the energy sector expands into coastal, offshore, and high-corrosion locations, the need for stable, low-maintenance materials continues to grow.

The main reasons behind the surge include:

Their resistance to chloride-induced corrosion

Reliable performance under both heat and pressure

Strong anti-fouling behavior in marine environments

Minimal degradation in long-term liquid-contact applications

Predictable thermal and mechanical stability

These attributes make CuNi alloy bars a preferred choice for desalination plants, offshore wind towers, marine vessels, power-plant heat-exchange systems, and industrial pipelines.

Applications Growing Across Key Energy Sectors

The global expansion of energy infrastructure is creating new opportunities for CuNi alloy materials. DLX Alloy is directly supplying bars for:

Heat exchangers and condensers in power plants

Cooling systems in industrial towers

Offshore wind structural components

Marine pipeline connectors

Desalination evaporators and brine-handling systems

Oil & gas equipment exposed to saltwater

Cryogenic components in energy storage projects

As energy projects become more interconnected and long-term oriented, project engineers are choosing materials that guarantee reliability. CuNi alloy bars provide exactly that: a stable solution with predictable lifecycle performance.

Industry Trends: Why Now Is a Key Moment for CuNi Materials

The timeline of global energy development shows several parallel trends:

Coastal regions are building larger desalination facilities

Nations investing in offshore wind are expanding turbine foundation systems

Marine engineering projects are scaling at unprecedented speed

Global demand for corrosion-resistant flow-control systems is rising

Oil & gas operators are upgrading and expanding ocean-connected pipelines

Power plants are modernizing thermal systems to improve efficiency

All these factors directly push the demand for CuNi alloy bars. The market is expected to grow steadily over the next decade, particularly in regions prioritizing renewable energy and marine infrastructure.

DLX Alloy’s Production Philosophy

DLX Alloy focuses on delivering materials engineered for real-world conditions—not just standardized specifications. Our production practices include:

Vacuum melting for improved purity

Controlled hot and cold working for uniform grain structure

Advanced heat treatments for mechanical consistency

Dimensional accuracy that supports automated machining

Rigorous testing for corrosion resistance and thermal stability

These processes ensure that every batch of CuNi alloy bars fits securely into the demanding requirements of energy and marine engineering.

We also work directly with engineers during early project stages, helping them choose the right alloy composition, mechanical condition, and bar dimensions to meet long-term durability standards.

What Sets DLX Alloy Apart

DLX’s advantage comes from combining high-volume capability with flexible customization. Instead of forcing customers into rigid specifications, we supply project-tailored solutions that integrate into their system designs.

Our advantages include:

High-purity CuNi alloy grades

Stable large-batch performance

Flexible diameter and length options

Shortened delivery cycles

Technical guidance based on real project experience

Strict quality traceability from melting to final packaging

This approach has strengthened DLX’s reputation as a dependable supplier for large-scale global projects.

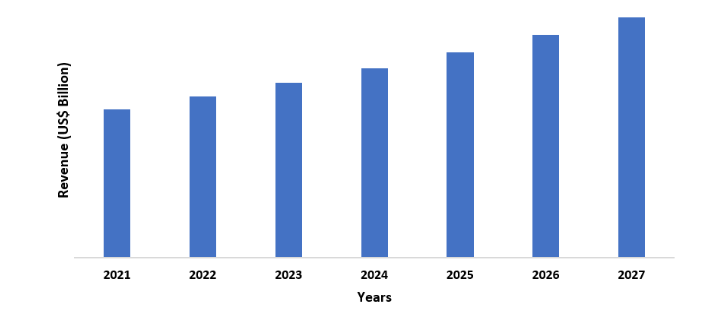

Outlook for the Global CuNi Alloy Market

As countries invest in resilient infrastructure, materials like CuNi alloy bars will continue to gain importance. With increasing focus on energy security, water supply stability, and corrosion-resistant engineering, the market for CuNi alloys is expected to expand for years.

DLX Alloy plans to continue scaling production, introducing new processing technology, and working closely with project developers across multiple sectors. Our long-term goal is to make CuNi alloy material supply faster, more consistent, and more accessible to global energy engineering teams.