Incoloy Alloy: Product Analysis, Industry Applications, and Material Comparison

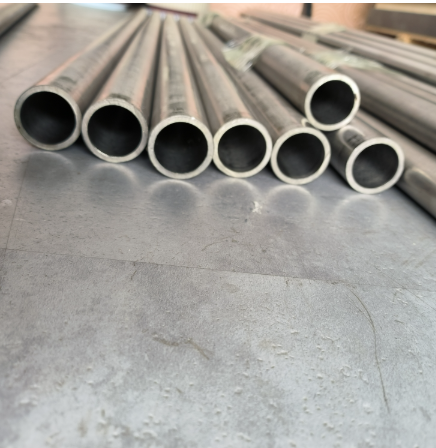

Our Incoloy Alloy products, such as Incoloy 800, 825, and 925, are nickel-iron-chromium alloys designed to tackle high temperatures and corrosive environments. With added elements like molybdenum and titanium, they offer exceptional resistance to oxidation, carburization, and stress corrosion cracking. Whether in bar, sheet, or tube form, our Incoloy alloys are built for durability in demanding applications like heat exchangers, chemical processing, and power generation.

Incoloy alloys are workhorses in extreme conditions across multiple sectors:

Chemical Processing: Heat exchangers and piping systems resist acids like sulfuric and phosphoric, ensuring long-term reliability.

Power Generation: Superheater tubing and nuclear reactor components withstand high temperatures up to 1500°F (816°C).

Oil and Gas: Piping and valves in sour gas environments handle corrosive gases and high pressures.

Petrochemicals: Furnace components and ethylene crackers benefit from Incoloy’s resistance to carburization.

Aerospace: Turbine components and exhaust systems rely on its high-temperature strength and creep resistance.

Marine: Seawater-cooled systems use Incoloy for its corrosion resistance in saline environments. Its versatility and robustness make Incoloy a top choice where failure isn’t an option.

2025 Market Insights

The global nickel alloy market, including Incoloy, was valued at $13.2 billion in 2024 and is expected to grow at a CAGR of 4.8% through 2030. In 2025, demand is driven by power generation (25% market share in 2023), chemical processing, and renewable energy projects like hydrogen production. Asia-Pacific, led by China and India, dominates due to infrastructure growth and industrialization. Nickel price volatility ($45,500/MT in Q1 2025) poses a challenge, but our streamlined supply chain ensures cost stability and reliable delivery.

Comparison with Other Materials

Incoloy alloys compete with Hastelloy, stainless steel, and titanium in high-performance applications. Here’s how they compare:

Parameter | Incoloy (e.g., 825) | Hastelloy (e.g., C-276) | Stainless Steel (e.g., 316) | Titanium (e.g., Grade 5) |

|---|---|---|---|---|

Corrosion Resistance | Excellent (acids, seawater, pitting) | Outstanding (acids, chlorides) | Good (rusts in chlorides) | Excellent (seawater, biocompatible) |

Max Operating Temp | 1500°F (816°C) | 1900°F (1038°C) | 1600°F (871°C) | 600°F (316°C) |

Tensile Strength | 85-100 ksi | 100-115 ksi | 75-90 ksi | 130-160 ksi |

Weldability | Good (standard methods) | Good (low risk of cracking) | Excellent | Moderate (specialized techniques) |

Density | 8.14 g/cm³ | 8.89 g/cm³ | 8.0 g/cm³ | 4.4 g/cm³ (lightest) |

Cost | High ($40,000/MT in 2025) | Higher ($50,000/MT) | Moderate | High |

Applications | Chemical, power, petrochemical | Chemical, oil & gas, power | General industrial, medical | Aerospace, medical, lightweight parts |

Pitting Resistance | Very good (PREN ~31 for 825) | Superior (PREN > 45) | Moderate (PREN ~25) | Good |

Incoloy’s Edge: Incoloy outperforms stainless steel in acidic and high-temperature environments, offers better cost-efficiency than Hastelloy for mid-range temperatures, and is easier to weld than titanium. It’s ideal for chemical and power applications requiring balanced performance.

Why Choose Our Incoloy Alloy?

Superior Durability: Resists oxidation, carburization, and stress corrosion cracking.

Custom Forms: Bars, sheets, and tubes tailored to your specifications.

Certified Quality: Meets ASTM B408, B425, and ASME standards with full certifications.

Fast Delivery: Global logistics for quick, reliable supply.

Expert Support: Guidance on alloy selection and application optimization.

FAQs

What makes Incoloy alloys ideal for chemical processing?

They resist acids and pitting corrosion, ensuring durability in reactors and piping.Can Incoloy handle high temperatures?

Yes, up to 1500°F (816°C), perfect for power generation and petrochemicals.How does Incoloy compare to stainless steel?

Incoloy excels in acidic and high-heat environments where stainless steel corrodes.Are Incoloy alloys weldable?

Absolutely, they weld easily with standard techniques, maintaining strength.What industries use Incoloy alloys?

Chemical processing, power generation, oil and gas, petrochemicals, aerospace, and marine.What’s the market outlook for Incoloy in 2025?

Growing at 4.8% CAGR, driven by power and chemical sectors, despite nickel price fluctuations.Is Incoloy suitable for marine applications?

Yes, its corrosion resistance makes it ideal for seawater-cooled systems.Why choose Incoloy over Hastelloy?

Incoloy offers similar corrosion resistance at a lower cost for mid-range temperatures.

Visual Description

Picture a stack of Incoloy 825 bars, their silver-gray surface gleaming under industrial lights in a power plant. In the background, a massive heat exchanger hums with activity, while a petrochemical furnace glows red-hot, showcasing Incoloy’s ability to thrive in extreme heat and corrosion.