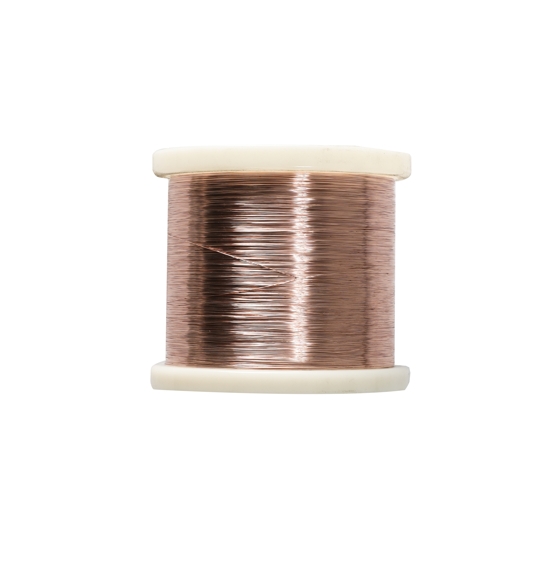

High-Performance CuNi1 Wire for Marine Engineering Corrosion Applications

Our High-Performance CuNi1 Wire is a standout solution for marine engineering and corrosion resistance challenges, built to thrive where the ocean’s toughest conditions test material limits. This isn’t just wire—it’s a reliable, long-lasting answer for seawater systems, offshore projects, and more. Let’s break down what makes this product exceptional, explore the industry landscape, highlight its key applications, and show why our approach gives us an edge, all while keeping things conversational and packed with value for anyone searching for top-tier marine engineering wire.

Our CuNi1 wire starts with a carefully crafted composition: roughly 90% copper, 10% nickel, plus about 1% iron and a dash of manganese. This mix is designed for marine environments, forming a tough, protective oxide layer when exposed to seawater. That layer keeps corrosion rates as low as 0.002 mm/year, meaning your setups stay intact longer. Unlike materials that need constant coatings or treatments, our wire fights pitting, crevice corrosion, and biofouling naturally. We’ve honed the manufacturing process too, using precision drawing and annealing to make it flexible yet strong—perfect for shaping into complex marine systems without losing durability.

For more details, pls directly contact us.

On the performance front, this wire delivers. It’s got a tensile strength of about 320 N/mm² in its annealed state, with the option to go higher through cold working. Its thermal conductivity, around 59 W/(m·K), makes it great for heat transfer in exchangers, while its 8.9 kg/dm³ density keeps things manageable weight-wise. What really sets it apart is its ability to handle harsh marine conditions—think high-velocity seawater flows up to 3.5 m/s without eroding or cracking under stress, chlorides, or sulfides. For anyone looking for corrosion resistant wire that cuts maintenance and boosts uptime, this is a no-brainer.

Let’s zoom out to the industry. Marine engineering is on a tear, fueled by offshore energy, renewable wind farms, and a boom in desalination plants. Recent trends show a big push for materials that last longer and align with sustainability goals—think lower carbon footprints through components that don’t need constant swapping. By 2025, regulations like those from the IMO are tightening on emissions and biofouling, making naturally antifouling materials like our CuNi1 wire a hot pick. It keeps surfaces clean without chemicals, cutting fuel use in shipping and meeting eco-standards head-on. The offshore oil and gas sector is leaning into durable wiring for subsea systems, where corrosion can rack up millions in losses. Desalination’s another growth area—water scarcity is driving new plants, and our wire’s resistance to saline conditions makes it a go-to for piping and exchangers. Aquaculture’s also surging, with fish farming growing over 5% yearly. Our wire in mesh form creates cages that stay clean and strong, boosting yields and fish health. If you’re after marine engineering wire that taps into these trends, CuNi1 is where it’s at.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 | |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 | |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

Applications are where this wire really flexes. In shipbuilding, it’s a star for seawater pipelines handling cooling, ballast, or fire systems. Its ductility means fewer joints, cutting leak risks and simplifying installs in tight ship spaces. Heat exchangers and condensers benefit from its thermal efficiency and resistance to erosive flows. Offshore platforms use it for hydraulic and instrumentation lines, keeping critical systems like valves and sensors running smoothly in salty conditions. For hulls, our wire reinforces cladding or sheathing, reducing fouling and potentially saving up to 15% on fuel by keeping surfaces smooth. In desalination, it tackles high-chlorine environments without breaking down, ensuring reliable freshwater production. Aquaculture loves it for fish cage meshes that promote water flow and resist fouling, leading to better stock health. Beyond marine, it even finds use in chemical plants or coastal power stations, but marine engineering is its sweet spot. Searching for versatile corrosion resistance applications? Our wire covers all bases.

What makes our company stand out? It’s our focus on quality and innovation that generic options can’t touch. While standard wires might skimp on alloy purity or processing, we double down on precision—our enhanced iron content speeds up protective film formation, letting you deploy faster without corrosion worries. We’re scalable too, delivering consistent specs whether you need a small batch for testing or bulk for a massive offshore project. Our CuNi1 wire’s biofouling resistance can cut maintenance costs by up to 50% in some setups, based on field data from similar alloys. Plus, we offer hands-on support—custom diameters, optional coatings, and integration tips tailored to your marine needs. This isn’t just about selling wire; it’s about delivering value that saves you time and money long-term.

Sustainability is another area where we shine. Our manufacturing leans on recycled copper and energy-efficient processes, aligning with the industry’s green push. With environmental impact under scrutiny, our wire helps you hit eco-targets without sacrificing performance. Trends suggest that choosing high-quality marine engineering wire like ours boosts ROI through lifespans stretching 20+ years in harsh seawater, compared to half that for cheaper alternatives.

Comparison Parameters Table

| Parameter | High-Performance CuNi1 Wire (90/10 CuNi) | Standard Copper Wire | Stainless Steel Wire (e.g., 316 Grade) |

|---|---|---|---|

| Composition | 90% Cu, 10% Ni, 1% Fe, 1% Mn | 99.9% Cu | Fe base, 16-18% Cr, 10-14% Ni, 2-3% Mo |

| Density (kg/dm³) | 8.9 | 8.96 | 8.0 |

| Tensile Strength (N/mm², annealed) | 320 | 220-250 | 500-700 |

| Corrosion Resistance in Seawater | Excellent (forms protective film, rate <0.002 mm/yr) | Poor (high pitting and oxidation) | Good (but susceptible to crevice corrosion) |

| Thermal Conductivity (W/(m·K)) | 59 | 398 | 16 |

| Biofouling Resistance | High (natural antifouling) | Low | Moderate (requires coatings) |

| Maximum Velocity Tolerance (m/s in seawater) | 3.5 | 1-2 | 4-5 |

| Cost-Effectiveness (Life-Cycle) | High (low maintenance, long lifespan) | Low (frequent replacements) | Medium (higher initial cost) |

| Applications Suitability | Marine pipelines, heat exchangers, wiring | Electrical wiring | General structural, but needs protection in marine |

In short, our High-Performance CuNi1 Wire is more than a product—it’s a solution built for the demands of marine engineering and corrosion resistance. From its robust design to its wide-ranging applications, it’s ready to tackle the industry’s toughest challenges. As the market shifts toward smarter, greener solutions, we’re leading with a wire that delivers durability, efficiency, and unmatched support. For anyone seeking reliable corrosion resistant wire, our CuNi1 is the answer, proven to perform and built to last.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is the material composition of High-Performance CuNi1 Wire?

High-Performance CuNi1 Wire is composed of approximately 90% copper, 10% nickel, with 1% iron and up to 1% manganese for improved strength and corrosion resistance.What are the key properties of High-Performance CuNi1 Wire?

It features excellent corrosion resistance in seawater, high mechanical strength with tensile values around 320 N/mm² in annealed form, good thermal conductivity of about 59 W/(m·K), and natural antifouling capabilities.What are the primary applications of High-Performance CuNi1 Wire in marine engineering?

It is widely used in seawater pipelines, heat exchangers, hydraulic and instrumentation tubing, ship hull reinforcements, and fish farming cages due to its durability in harsh marine conditions.How does High-Performance CuNi1 Wire perform in corrosion-prone environments?

It forms a thin, adherent protective oxide film in seawater, reducing corrosion rates to as low as 0.002 mm/year, and resists pitting, crevice corrosion, and biofouling effectively.What industry trends are driving the adoption of High-Performance CuNi1 Wire?

Rising demand for sustainable, low-maintenance materials in offshore energy, desalination, and aquaculture, coupled with advancements in alloy processing for cost-effective marine solutions.Is High-Performance CuNi1 Wire suitable for high-flow marine applications?

Yes, it handles seawater velocities up to 3.5 m/s in pipelines and withstands impingement without significant erosion, making it ideal for dynamic marine systems.What makes High-Performance CuNi1 Wire advantageous for long-term marine use?

Its superior resistance to stress corrosion cracking, hydrogen embrittlement, and sulfide attacks ensures extended service life, reducing downtime and replacement costs in marine setups.How does High-Performance CuNi1 Wire contribute to environmental trends in the industry?

It supports eco-friendly marine practices by minimizing biofouling without chemicals, aligning with global shifts toward greener shipping and offshore infrastructure.