Precision CuNi10 Wire for Marine and Electrical Applications

Our CuNi10 wire is a top performer when you need precision and toughness, especially in marine and electrical applications. This copper-nickel alloy, with its 10% nickel content and often a dash of iron (CuNi10Fe), is designed to handle challenging environments while delivering reliable electrical performance.

Let’s dive into what makes CuNi10 wire special. Its standout feature is corrosion resistance, particularly in saltwater, which makes it a favorite for marine applications like ship wiring, offshore platforms, and desalination systems. It’s tough enough to withstand the harshest coastal conditions without rusting out, which is a game-changer for marine engineers. On the electrical side, CuNi10 offers solid conductivity—around 20% IACS—making it perfect for resistors, heating cables, and low-temperature thermocouples where precision is key.

This wire is also a breeze to work with. Its excellent formability means you can bend, weld, or shape it into whatever your project calls for, whether that’s thin wires for electronics or strips for custom components. Need something specific? We can tailor the size or form to fit your exact needs, saving you time and hassle during manufacturing.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

The industry’s seeing a big push toward materials that balance performance with sustainability, and CuNi10 wire fits right in. It’s fully recyclable, which is a win for eco-conscious projects, and its durability means you’re not constantly replacing parts. As marine industries expand and electrical systems get more complex, demand for reliable, corrosion-resistant materials like CuNi10 is on the rise. We’re also seeing more interest in energy-efficient solutions, and CuNi10’s stable performance in heating systems aligns perfectly with that trend.

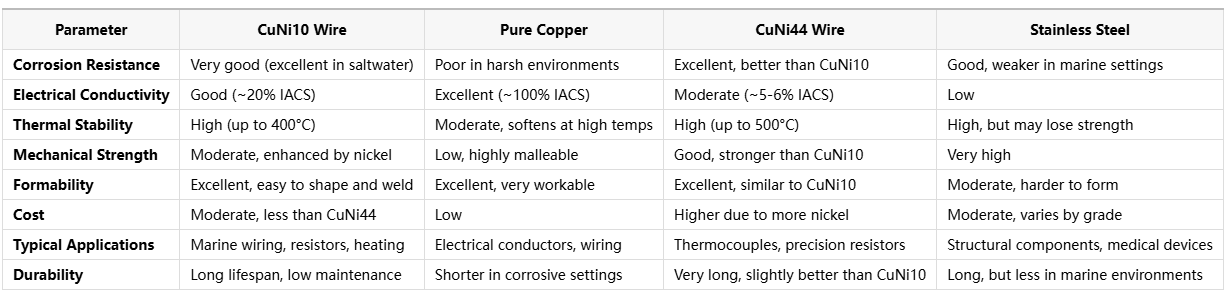

Compared to other materials, CuNi10 holds its own. Pure copper’s a conductivity champ but can’t handle corrosive environments. CuNi44, with higher nickel, is tougher against corrosion but has lower conductivity, making CuNi10 a better fit for applications needing a balance of both. Stainless steel’s strong but falls short in marine settings and electrical performance. CuNi10 strikes the sweet spot for marine and electrical projects.

We produce our CuNi10 wire to meet rigorous standards like ISO 9001, ensuring you get consistent, high-quality performance every time. Whether you’re wiring a ship or building precision electrical systems, this wire’s got your back. Got a unique spec in mind? Let us know, and we’ll make it happen.

About Us:

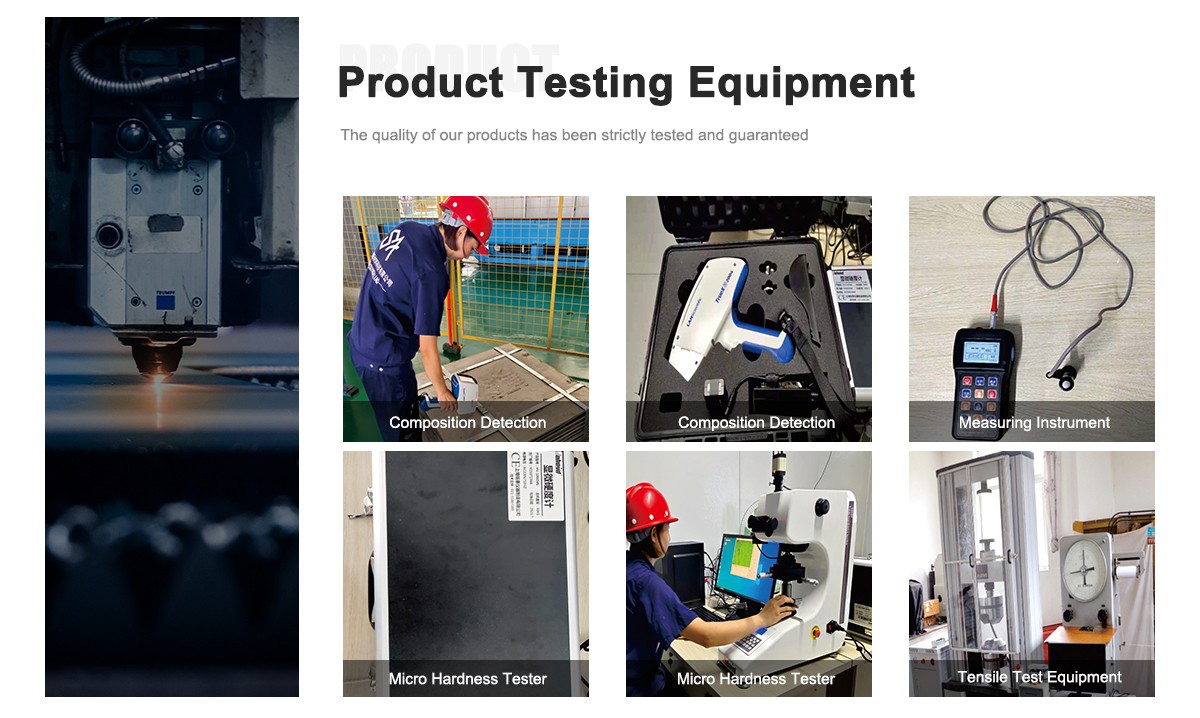

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is CuNi10 wire made of?

It’s a copper-nickel alloy with 10% nickel, often with a touch of iron (CuNi10Fe) to boost corrosion resistance.What are the main uses for CuNi10 wire?

It’s used in marine wiring, electrical resistors, heating systems, and precision components in marine and electrical industries.How does CuNi10 wire perform in marine environments?

It’s a rock star, resisting saltwater corrosion like few other materials, perfect for ship wiring and offshore systems.Can CuNi10 wire handle high temperatures?

Yep, it’s stable up to about 400°C, making it great for heating cables and low-temperature thermocouples.Is CuNi10 wire cost-effective?

It’s pricier than pure copper, but its corrosion resistance and durability make it a smart choice for long-term savings.How does CuNi10 wire compare to higher-nickel CuNi alloys?

It has higher electrical conductivity than CuNi44 but slightly less corrosion resistance, ideal for less extreme environments.Can CuNi10 wire be customized?

Totally! We can supply it as wire, strip, or ribbon and adjust specs to meet your electrical or mechanical needs.Is CuNi10 wire eco-friendly?

It’s recyclable, supporting sustainable practices, and its long lifespan reduces the need for frequent replacements.