Versatile CuNi Resistance Wire for Custom Engineering Solutions

Our CuNi resistance wire is like the Swiss Army knife of alloys—versatile, reliable, and ready to tackle your toughest engineering challenges. This copper-nickel alloy is our pride and joy for custom projects, offering the flexibility and performance you need to bring your ideas to life.

What makes this wire so special is how customizable it is. Whether you need a specific resistivity for a precision resistor or a unique shape for a complex component, we can dial in the nickel content—think CuNi10 to CuNi44—or deliver it as wire, strip, or ribbon. It’s a dream for engineers working on bespoke solutions in electronics, automotive, or even aerospace.

Corrosion resistance is another feather in its cap. With nickel and additives like iron, this wire shrugs off saltwater, chemicals, and humidity. That’s why it’s a staple in marine engineering, from ship wiring to offshore sensors, where other materials would rust out fast. It’s built to keep performing, no matter the environment.

For applications like heating elements or thermocouples, CuNi wire’s got you covered. It’s stable up to 400°C, with some grades pushing 500°C, and its consistent electrical resistivity makes it perfect for precise control in resistors or temperature sensors. Plus, it’s super easy to work with—bend it, weld it, shape it without a hassle, which saves serious time in manufacturing.

The industry’s all about materials that can do more while being sustainable, and CuNi resistance wire fits the bill. It’s recyclable, which is awesome for eco-friendly projects, and its long lifespan means fewer replacements, less waste, and lower costs over time. As custom engineering and IoT solutions boom, CuNi’s versatility is in high demand.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 | |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

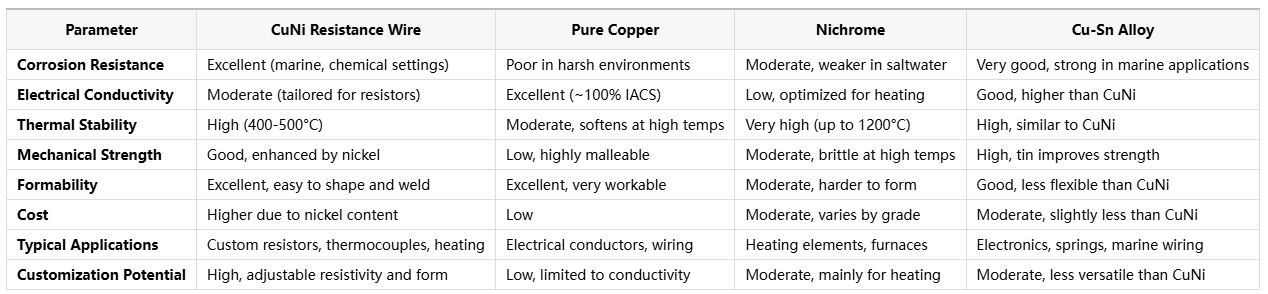

Compared to other materials, CuNi stands tall. Pure copper’s a conductivity king but flops in harsh conditions. Nichrome’s great for high-heat applications but less flexible for precision work. Cu-Sn alloys are solid but don’t match CuNi’s customization potential or marine-grade corrosion resistance.

We craft our CuNi resistance wire to meet top standards like ISO 9001, so you’re getting quality you can bank on. Whether you’re designing cutting-edge electronics or rugged marine systems, this wire’s ready to make your project pop. Got a specific vision? Let us know, and we’ll tailor it to perfection.

Highly customizable for specific engineering needs

Excellent corrosion resistance in diverse environments

Stable electrical resistivity for precise applications

Superior formability for complex manufacturing

Long durability with low maintenance costs

About Us:

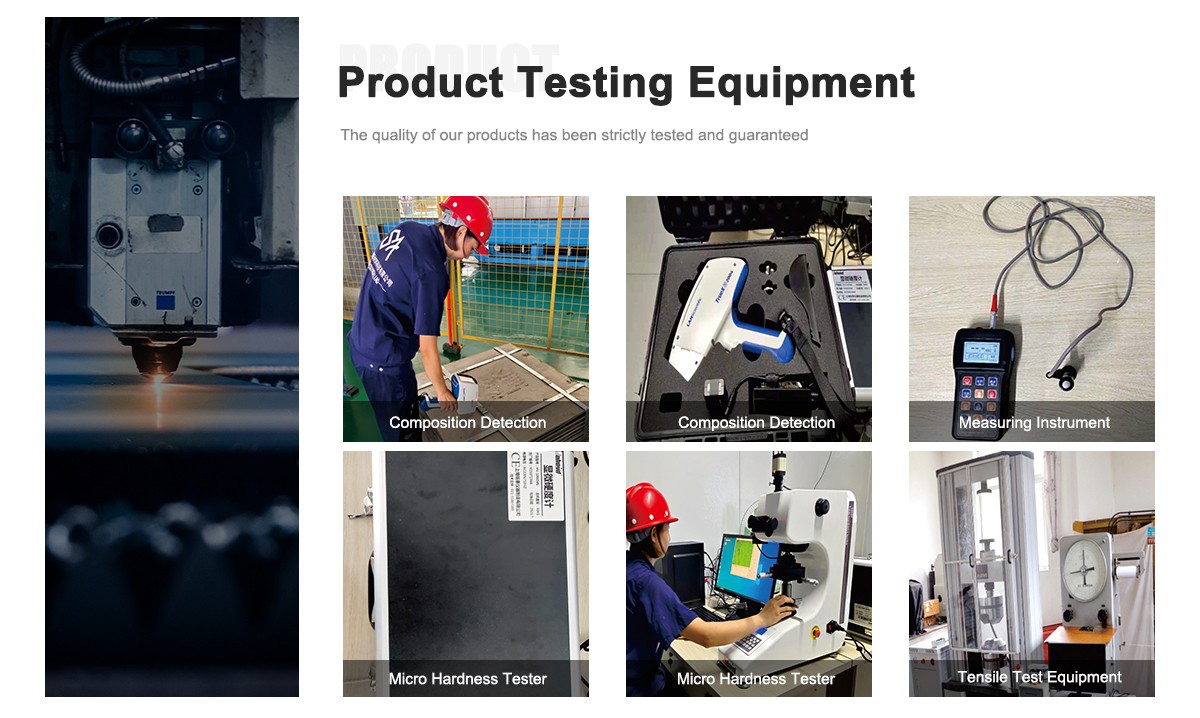

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is CuNi resistance wire used for?

It’s used in custom resistors, heating elements, thermocouples, and precision components across industries like electronics, automotive, and marine engineering.

How customizable is CuNi resistance wire?

Very! We can tweak nickel content (e.g., CuNi10, CuNi44), size, or form (wire, strip, ribbon) to match your project’s exact resistivity or mechanical requirements.

Does CuNi resistance wire resist corrosion?

Big time—nickel and additives like iron make it super resistant to corrosion, especially in saltwater, chemicals, or humid environments.

Can it handle high temperatures?

Yup, most grades are stable up to 400°C, with some like CuNi30Mn hitting 500°C, perfect for heating and high-temp applications.

Is CuNi resistance wire expensive?

It costs more than pure copper due to nickel, but its long life and reliability make it a cost-effective choice for custom solutions.

How does CuNi resistance wire compare to nichrome?

CuNi has better corrosion resistance, especially in marine settings, while nichrome handles higher temperatures but is less versatile for precision resistors.

Is it easy to work with in manufacturing?

Totally, its excellent formability means it’s easy to bend, weld, or shape, saving time and effort in custom engineering projects.

Is CuNi resistance wire eco-friendly?

It’s recyclable, aligning with green initiatives, and its durability reduces replacements, cutting down on waste over time.