High-Performance Hastelloy C-276 Coil in Aerospace and Power Generation

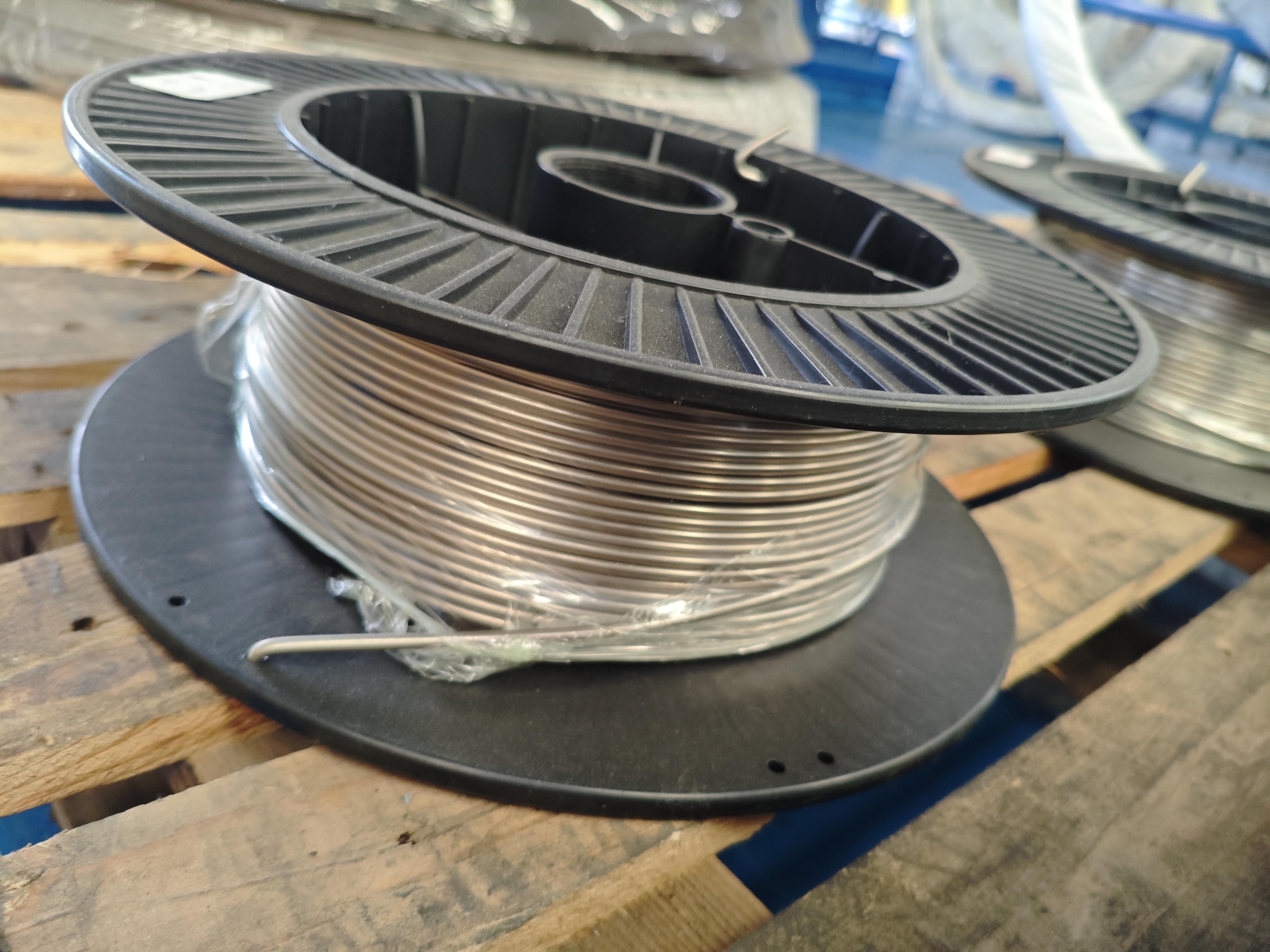

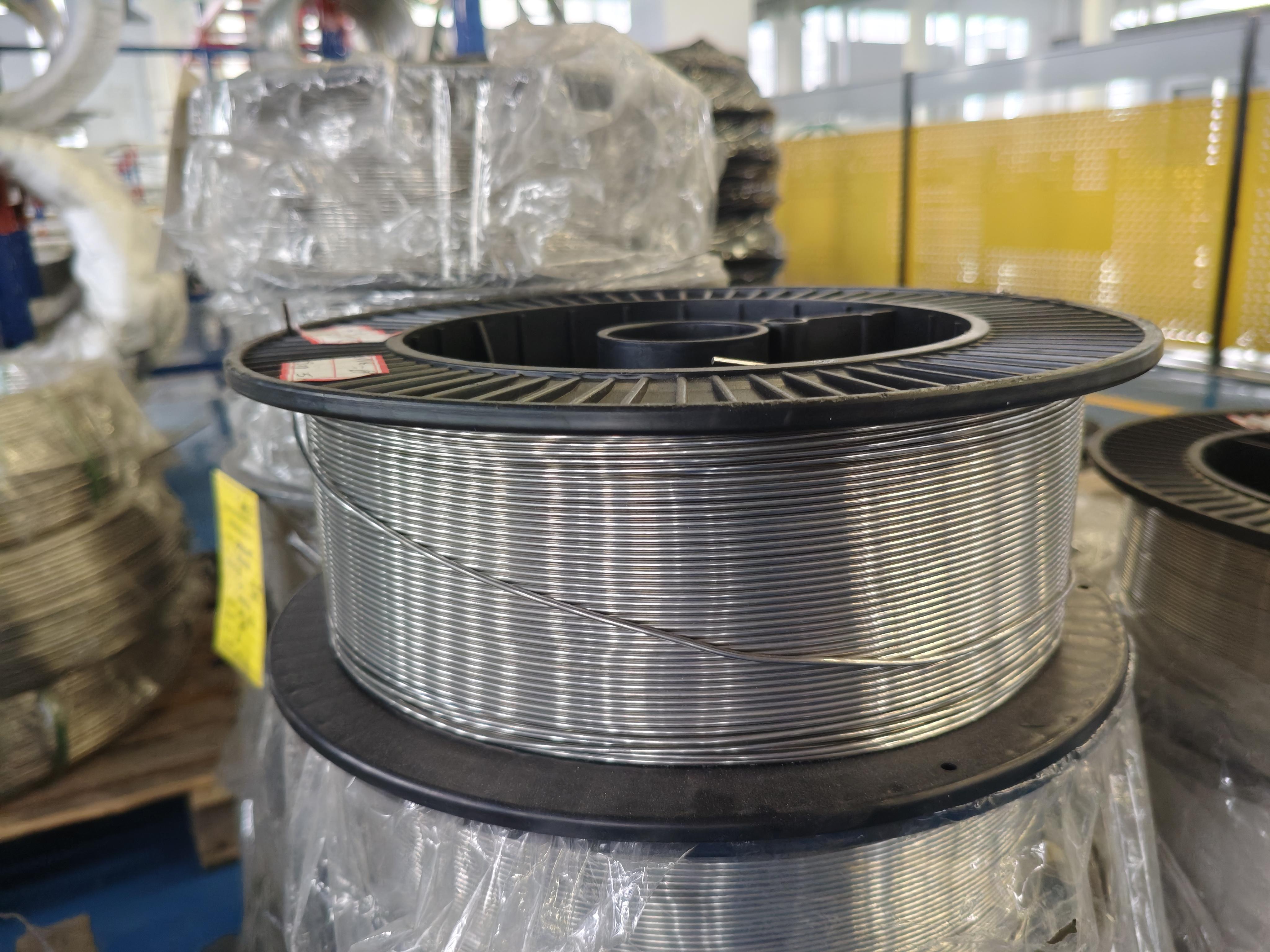

Our High-Performance Hastelloy C-276 coil is a top-notch nickel alloy designed to shine in the demanding worlds of aerospace and power generation. Made with about 57% nickel, 15-17% molybdenum, 14.5-16.5% chromium, plus tungsten and iron, this alloy is a corrosion-resistant, high-temperature superstar. Built to meet ASTM B575 and UNS N10276 standards, it comes in thicknesses from 0.025” to 1.000” and customizable sizes to suit any project. Whether you’re crafting jet engine components or power plant boilers, our coil delivers unmatched durability and reliability.

This coil is a beast when it comes to resisting pitting, crevice corrosion, and stress corrosion cracking, even in extreme environments like high-heat turbines or acidic gas streams. It’s not just tough—it’s easy to work with, offering excellent weldability, formability, and machinability without losing its strength. From aerospace turbines to power generation scrubbers, our Hastelloy C-276 coil keeps your equipment running longer, cutting down on maintenance and downtime.

For more details, pls directly contact us.

The global nickel alloy market, including our Hastelloy C-276 coil, was valued at USD 1.2 billion in 2023 and is expected to hit USD 1.8 billion by 2032, growing at a CAGR of 5.3%. Aerospace and power generation are key drivers, as both industries demand materials that can handle extreme temperatures, corrosive gases, and high-stress conditions. With stricter environmental regulations and a push for sustainability, companies are leaning toward durable, low-maintenance materials to reduce waste and operational costs.

In aerospace, the need for lightweight, corrosion-resistant materials is growing as manufacturers design more efficient, high-performance engines for commercial and military aircraft. Power generation, especially in nuclear, geothermal, and fossil-fuel plants, requires alloys that can withstand high temperatures and corrosive environments like acidic steam or flue gases. Our Hastelloy C-276 coil meets these needs with its ability to resist corrosion and maintain strength up to 1900°F (1038°C).

Emerging trends in renewable energy, such as geothermal and solar thermal plants, are increasing demand for high-performance alloys. The aerospace sector is also seeing growth in space exploration, where materials must endure extreme conditions. Meanwhile, sustainability trends are pushing power generation toward cleaner, more efficient systems, making our coil’s durability and low maintenance a perfect fit. As these industries evolve, our Hastelloy C-276 coil remains a go-to choice for applications where reliability is critical.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

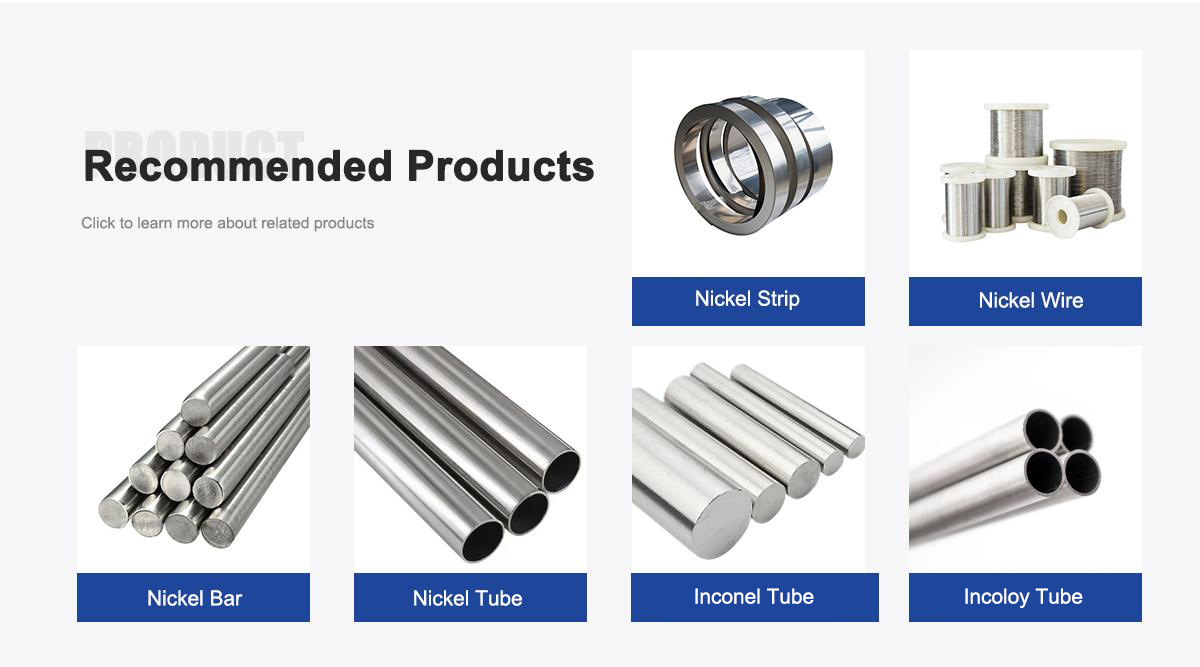

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Our Hastelloy C-276 coil is a powerhouse in aerospace and power generation, but its versatility extends to other industries too. In aerospace, it’s used in jet engine components, turbine blades, and exhaust systems, where it handles high temperatures and corrosive gases without breaking a sweat. Its lightweight strength and corrosion resistance make it ideal for aircraft operating in extreme conditions.

In power generation, our coil is a staple in boilers, steam generators, and flue gas desulfurization systems, resisting acidic gases and high heat in nuclear, fossil-fuel, and geothermal plants. The chemical processing industry uses it in reactors and heat exchangers for handling aggressive acids like sulfuric and hydrochloric. In oil and gas, it’s found in pipelines and offshore platforms, combating sour gas and chloride corrosion.

The pharmaceutical industry relies on it for sterile equipment like reactors and tanks, thanks to its non-toxic properties and resistance to harsh cleaning agents. In marine engineering, it’s used in ship components and offshore rigs to fight seawater corrosion. The pollution control sector benefits from its use in scrubbers and exhaust systems, handling acidic gases with ease. Its ability to perform across these demanding applications makes it a must-have for high-stakes projects.

Company Comparison and Our Advantages

Our Hastelloy C-276 coil sets the bar high, and we’re proud to lead the industry. We source only the best raw materials, ensuring every coil meets ASTM B575 and UNS N10276 standards. Available in thicknesses from 0.025” to 1.000” and customizable sizes, our coils are tailored to your project’s exact needs, from specific dimensions to surface finishes.

Our manufacturing process is cutting-edge, delivering precision and consistency while prioritizing sustainability to reduce waste and energy use. We provide full material traceability and detailed documentation, making compliance with industry regulations straightforward. Unlike others, our coils are designed for easy fabrication—welding, machining, and forming are hassle-free, thanks to the alloy’s low carbon content and excellent workability.

We offer value-added services like custom cutting, polishing, and heat treatment, all tailored to your specifications. Our expert team supports you every step of the way, from material selection to on-time delivery. While some companies cut corners, we focus on delivering a product that lasts, saving you maintenance costs and downtime. Our global supply chain ensures fast, reliable delivery, no matter where your project is located.

|

Property/Feature |

Hastelloy C-276 |

Inconel 625 |

Stainless Steel 316L |

|---|---|---|---|

|

Nickel Content (%) |

~57 |

~61 |

~10-14 |

|

Molybdenum Content (%) |

15-17 |

8-10 |

2-3 |

|

Chromium Content (%) |

14.5-16.5 |

20-23 |

16-18 |

|

Tensile Strength (ksi) |

110 min |

120 min |

70-85 |

|

Yield Strength (ksi) |

52 min |

60 min |

25-40 |

|

Corrosion Resistance |

Superior in acids and high heat |

Strong in high-temp oxidation |

Moderate, weaker in harsh conditions |

|

Temperature Resistance |

Up to 1900°F (1038°C) |

Up to 1800°F (982°C) |

Up to 1600°F (871°C) |

|

Weldability |

Excellent, low carbon |

Good, requires careful handling |

Good, less resistant post-weld |

|

Applications |

Aerospace, power generation |

Aerospace, high-temp uses |

General industrial use |

Our High-Performance Hastelloy C-276 coil is a game-changer for aerospace, power generation, and beyond. Its nickel-molybdenum-chromium composition delivers exceptional corrosion resistance, high-temperature stability, and durability, making it perfect for jet engines, power plant boilers, and other demanding applications. With industry trends favoring sustainable, long-lasting materials, our coil is a smart choice that boosts efficiency and cuts costs.

We take pride in delivering a product that’s tough, reliable, and easy to work with. From rigorous quality control to customizable solutions and global delivery, we’re committed to your success. Choose our Hastelloy C-276 coil for a material that stands up to the toughest conditions, backed by a company focused on quality, sustainability, and getting it right every time.

For more details, pls directly contact us.

|

|

|

|

|

|

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the composition of Hastelloy C-276 coil?

It’s a nickel-based alloy with ~57% nickel, 15-17% molybdenum, 14.5-16.5% chromium, 3-4.5% tungsten, 4-7% iron, and trace elements like cobalt and carbon. -

Which industries use this coil?

Aerospace, power generation, chemical processing, oil and gas, pharmaceuticals, and pollution control. -

What are its key applications in aerospace and power generation?

Used in jet engine components, turbine blades, boilers, steam generators, and flue gas desulfurization systems. -

How does it handle corrosion?

It resists pitting, crevice corrosion, and stress corrosion cracking in high-temperature and acidic environments. -

Is it easy to weld?

Yes, it welds smoothly using TIG, MIG, or shielded metal-arc methods, thanks to low carbon content. -

What temperatures can it withstand?

It performs reliably up to 1900°F (1038°C), ideal for aerospace and power generation applications. -

Is it cost-effective for high-performance uses?

Higher upfront cost but saves money with its long lifespan and low maintenance needs. -

What standards does it meet?

Complies with ASTM B575, ASME, and UNS N10276 for consistent quality and performance.