UNS N10665 Hastelloy B-2 Tubing for Chemical and Petrochemical Processing

In the chemical and petrochemical sectors, handling corrosive chemicals safely and efficiently requires materials that can withstand the toughest conditions. UNS N10665 Hastelloy B-2 Tubing is a high-performance nickel-molybdenum alloy designed specifically for reducing acid environments, providing unparalleled corrosion resistance and mechanical reliability. DLX specializes in manufacturing and supplying top-quality Hastelloy B-2 Tubing that meets ASTM standards and global industrial requirements.

For more details, pls directly contact us.

Hastelloy B-2, designated UNS N10665, combines nickel with molybdenum to create a material optimized for resistance to hydrochloric, sulfuric, and phosphoric acids. Unlike many other nickel alloys, B-2 is tailored for reducing acid environments, offering exceptional corrosion resistance without compromising mechanical strength.

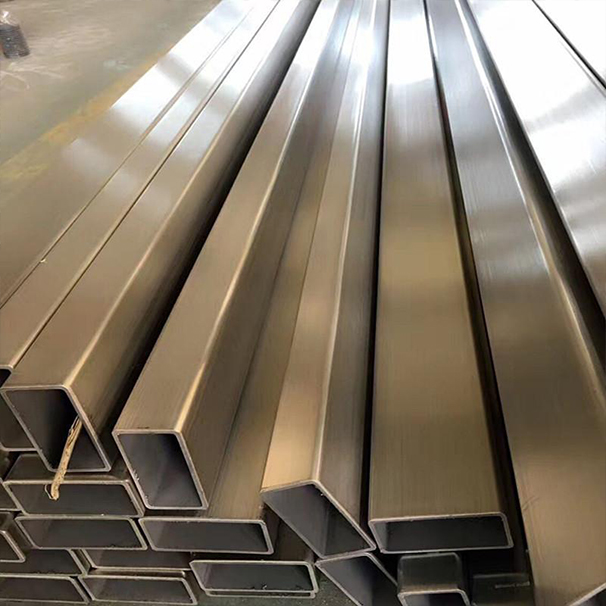

DLX produces seamless tubes under ASTM B622 or B3 standards, ensuring precise dimensions and eliminating weld points that could compromise integrity. Every tube is subjected to strict quality control procedures including chemical composition verification, mechanical testing, and corrosion resistance evaluation, guaranteeing reliability in even the harshest chemical environments.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Hastelloy B-2 Tubing is widely used across multiple sectors:

-

Chemical Processing: Ideal for hydrochloric and sulfuric acid handling lines, heat exchangers, evaporators, and reactors.

-

Petrochemical Industry: Ensures long-term reliability in pipelines, reactors, and condensers exposed to reducing acids.

-

Pharmaceutical Manufacturing: Supports chemical processes requiring resistance to strong acids while maintaining purity.

-

Marine Applications: Suitable for seawater handling and desalination systems where localized reducing environments exist.

-

Environmental Protection: Used in chemical neutralization systems, waste treatment, and pollution control equipment.

-

Research & Laboratory Equipment: Provides chemical compatibility for experimental setups involving reducing acids.

DLX provides seamless tubing in customized lengths, diameters, and wall thicknesses, tailored for optimal performance in each application.

The global demand for nickel-molybdenum alloys such as Hastelloy B-2 is rising due to the growing complexity and aggressiveness of chemical and petrochemical processes. Factors contributing to this demand include:

-

Chemical Plant Expansion: Facilities increasingly handle corrosive reducing acids, requiring specialized materials.

-

Petrochemical Facility Growth: Pipelines, reactors, and condensers demand corrosion-resistant tubing to ensure longevity.

-

Pharmaceutical Industry Needs: Acid-resistant tubing is essential for high-purity production and compliance with strict regulations.

-

Marine Infrastructure Projects: Seawater-exposed systems with reducing conditions require durable alloys.

-

Environmental Protection Systems: Advanced waste treatment and chemical neutralization systems demand corrosion-resistant materials.

DLX is strategically positioned to supply these markets with high-quality, reliable tubing and expert technical support.

Comparison Table: Hastelloy B-2 Tubing vs Alternatives

| Property | Hastelloy B-2 Tubing (UNS N10665) | Hastelloy C-22 Tubing (UNS N06022) | Stainless Steel 316L Tubing |

|---|---|---|---|

| Base Material | Nickel-Molybdenum | Nickel-Chromium-Molybdenum-Tungsten | Iron-Nickel-Chromium |

| Oxidizing Resistance | Limited | Excellent | Moderate |

| Reducing Resistance | Excellent | Very Good | Limited |

| High-Temperature Strength | Good | Excellent | Moderate |

| Chloride Resistance | Moderate | Excellent | Moderate |

| Seamless Availability | Yes (ASTM B622/B3) | Yes (ASTM B622) | Yes |

| Applications | Chemical, petrochemical, pharma, marine | Marine, chemical, petrochemical | Food, mild chemicals, pharma |

| Pitting/Crevice Resistance | Moderate | Excellent | Limited |

| Temperature Range | Up to ~500°C | Up to ~1000°C | Up to ~870°C |

| Cost Level | Moderate | Higher | Lower |

DLX differentiates itself by offering not only superior Hastelloy B-2 Tubing but also complete solutions:

-

ASTM Compliance: All tubing meets ASTM B622 or B3 standards for seamless nickel-molybdenum alloys.

-

Customization: Tubes are available in a wide range of diameters, wall thicknesses, and lengths for project-specific needs.

-

Quality Assurance: Comprehensive chemical, mechanical, and corrosion testing ensures performance reliability.

-

Technical Support: Guidance on welding, machining, and installation optimizes long-term performance.

-

Global Logistics: Efficient supply chains ensure timely delivery worldwide.

-

Value for Investment: High-performance materials offered with competitive pricing for specialized applications.

This combination of quality, technical expertise, and global delivery capability makes DLX a preferred partner for industries using Hastelloy B-2 Tubing.

Selecting the right material is critical. While stainless steel 316L is affordable, it cannot withstand strong reducing acids over time. Hastelloy C-22 and C-276 perform well in mixed oxidizing/reducing environments but are often over-specified for purely reducing acid conditions. Hastelloy B-2 offers specialized corrosion resistance, mechanical integrity, and cost-effectiveness for chemical and petrochemical pipelines, heat exchangers, and reactors. DLX’s seamless tubing enhances these advantages by removing weld-related weaknesses and ensuring consistent performance.

The market for ASTM-compliant UNS N10665 Hastelloy B-2 Tubing is growing across key sectors:

-

Expansion of chemical and petrochemical plants handling reducing acids.

-

Pharmaceutical manufacturing requiring high-purity, acid-resistant systems.

-

Marine and desalination projects with localized reducing environments.

-

Environmental protection and waste treatment systems requiring corrosion-resistant tubing.

DLX is fully equipped to meet this demand with advanced production capabilities, strict quality control, and a reliable global supply chain.

Hastelloy B-2 Tubing is a high-performance nickel-molybdenum solution designed for superior resistance to reducing acids in chemical and petrochemical industries. Its specialized corrosion resistance, mechanical strength, and seamless construction make it ideal for critical applications where durability and reliability are essential.

DLX delivers this high-performance tubing with precise quality control, customizable dimensions, technical support, and global logistics. Industries choosing DLX gain access to reliable, long-lasting UNS N10665 Hastelloy B-2 Tubing capable of performing in the most demanding reducing acid environments.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is UNS N10665 Hastelloy B-2 Tubing?

A1: It is a nickel-molybdenum alloy tubing engineered for superior resistance to reducing acids in chemical and petrochemical processes.

Q2: Which industries primarily use Hastelloy B-2 Tubing?

A2: Chemical processing, petrochemical, pharmaceuticals, marine, and environmental engineering industries.

Q3: How does Hastelloy B-2 perform in reducing acid environments?

A3: It provides outstanding resistance to hydrochloric, sulfuric, and phosphoric acids, maintaining structural integrity.

Q4: Is Hastelloy B-2 suitable for oxidizing environments?

A4: It has limited resistance to strong oxidizers, so precautions are needed for highly oxidizing applications.

Q5: What temperature range can Hastelloy B-2 Tubing handle?

A5: It reliably performs up to approximately 500°C in reducing acid conditions.

Q6: Are these tubes seamless or welded?

A6: DLX offers seamless tubing, which eliminates weld points and ensures maximum structural strength.

Q7: How does Hastelloy B-2 compare with other nickel alloys?

A7: It excels in reducing acid resistance where many other nickel alloys may fail, making it specialized for certain chemical applications.

Q8: Why choose DLX for Hastelloy B-2 Tubing?

A8: DLX provides ASTM-compliant manufacturing, precision quality control, technical support, and reliable global supply.