Nickel Alloy C-276 Coil: Properties and Uses in Chemical Processing

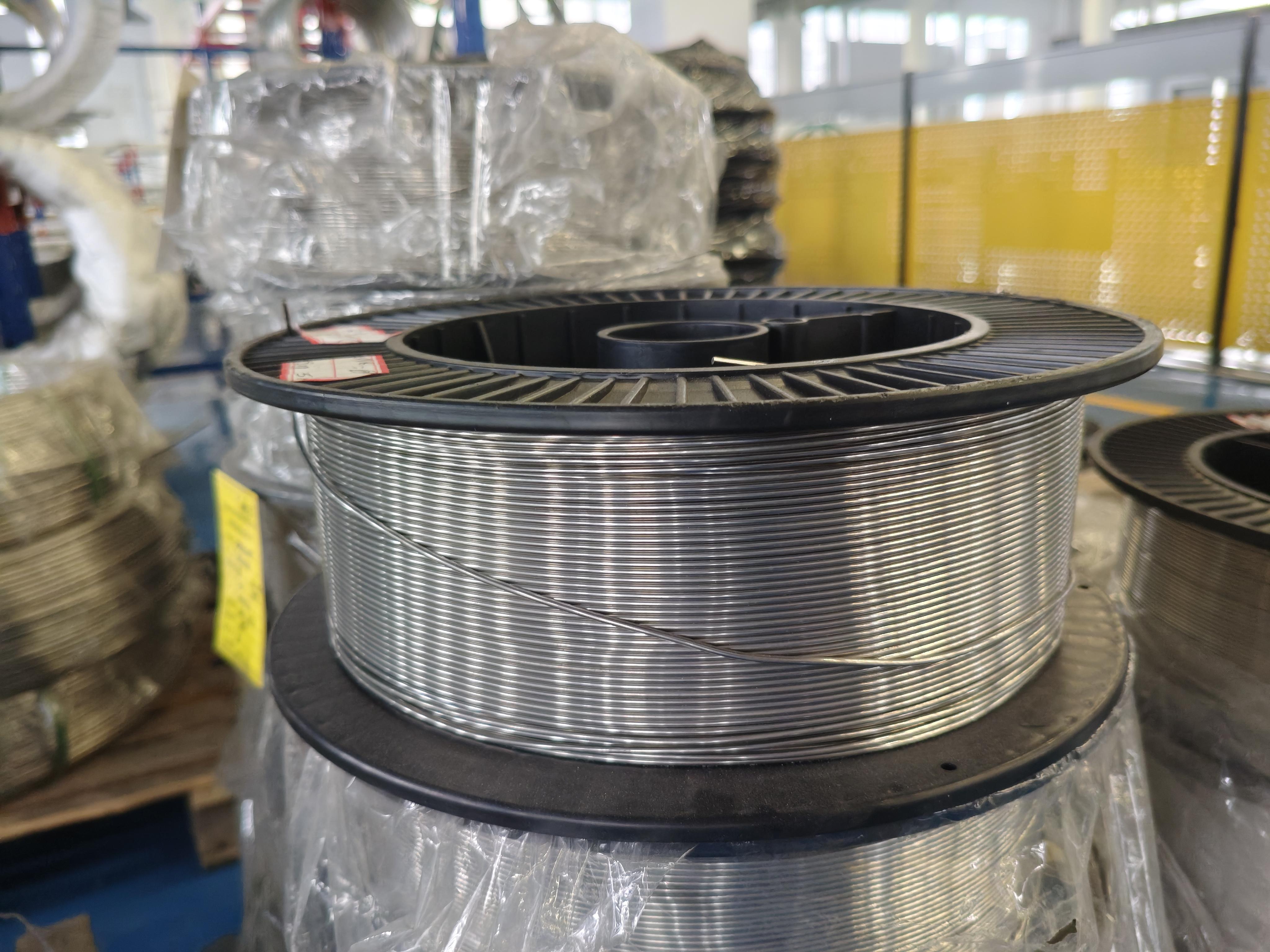

Our Nickel Alloy C-276 coil, commonly known as Hastelloy C-276, is a powerhouse in the world of high-performance alloys. This nickel-molybdenum-chromium blend, with roughly 57% nickel, 15-17% molybdenum, 14.5-16.5% chromium, plus dashes of tungsten and iron, is engineered to laugh in the face of corrosion. It’s the go-to material for environments that would chew up lesser alloys—think acidic chemicals, high temperatures, and salty conditions. Compliant with ASTM B575 and UNS N10276 standards, our coils come in thicknesses from 0.025” to 1.000”, making them adaptable for all sorts of projects.

What makes our Nickel Alloy C-276 coil special? It’s got top-notch resistance to pitting, crevice corrosion, and stress corrosion cracking, even in the harshest settings like sulfuric or hydrochloric acid baths. Whether you’re building chemical reactors, heat exchangers, or offshore rigs, this coil keeps things running smoothly, cutting down on maintenance and downtime. We craft it to be easy to work with—welding, forming, and machining are no sweat—while maintaining its strength and durability. It’s the kind of material that makes your job easier and your equipment last longer.

For more details, pls directly contact us.

The market for high-performance alloys like Nickel Alloy C-276 coil is growing fast, driven by the need for materials that can handle extreme conditions without breaking down. Valued at USD 1.2 billion in 2023, the global nickel alloy market is expected to reach USD 1.8 billion by 2032, with a CAGR of 5.3%. Industries like chemical processing, oil and gas, and power generation are pushing this growth, as they demand materials that resist corrosion and last longer to meet strict environmental and safety standards.

Sustainability is a key trend. Companies want materials that reduce maintenance and replacement costs, aligning with eco-friendly goals. Nickel Alloy C-276 fits perfectly, offering a long lifespan in harsh environments, which cuts down on waste and energy use. The chemical processing industry, handling acids like sulfuric and hydrochloric, relies heavily on this alloy for reactors and piping. In oil and gas, it’s critical for sour gas wells and offshore platforms, where corrosion from hydrogen sulfide and seawater is a constant threat. Power generation, especially in nuclear and geothermal plants, also leans on this alloy for its heat and corrosion resistance.

Looking ahead, renewable energy and advanced manufacturing are boosting demand. Geothermal and solar power plants use Nickel Alloy C-276 for its ability to withstand corrosive steam and high temperatures. The pharmaceutical sector is another growth area, valuing the alloy’s non-toxic properties and resistance to aggressive cleaning agents. As industries prioritize durability and efficiency, Nickel Alloy C-276 coil remains a top choice for mission-critical applications.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Our Nickel Alloy C-276 coil is a workhorse across multiple industries. In chemical processing, it’s used for reactors, heat exchangers, and piping systems that handle corrosive acids like sulfuric, hydrochloric, and phosphoric. Its resistance to pitting and crevice corrosion ensures long-term reliability in these tough environments.

In the oil and gas sector, our coil is a game-changer for offshore rigs, pipelines, and sour gas wells, standing up to hydrogen sulfide and chloride-rich conditions. For power generation, it’s found in boilers, steam generators, and flue gas desulfurization systems, handling high temperatures and corrosive gases with ease. The pharmaceutical industry relies on it for sterile equipment like reactors and storage tanks, thanks to its non-toxic nature and ability to withstand harsh sterilization processes.

Marine engineering is another key area, where our coil is used in ship components and offshore platforms to combat seawater corrosion. In the pulp and paper industry, it’s critical for digesters and bleaching systems that deal with corrosive chemicals and high heat. The pollution control sector also benefits, using our coil in scrubbers and exhaust systems to handle acidic gases. Its versatility and toughness make it a go-to material for any application where failure isn’t an option.

Company Comparison and Our Advantages

Our Nickel Alloy C-276 coil sets the standard in the industry, and we’re proud to lead the way. We start with the highest-quality raw materials, ensuring every coil meets ASTM B575 and UNS N10276 standards. Available in a range of sizes and thicknesses (0.025” to 1.000”), our coils are customizable to fit your exact needs, whether it’s a specific width or surface finish.

Our manufacturing process is cutting-edge, delivering precision and consistency every time. We’re big on sustainability, optimizing production to reduce waste and energy use, which aligns with today’s eco-conscious trends. Unlike others, we provide full material traceability and documentation, making compliance a breeze. Our coils are designed for easy fabrication—welding, machining, and forming are straightforward, thanks to the alloy’s low carbon content and excellent workability.

We go beyond just supplying coils. Our value-added services include custom cutting, polishing, and heat treatment, tailored to your project. Our expert team is here to guide you, from choosing the right grade to ensuring on-time delivery. While some companies might skimp on quality, we focus on delivering a product that lasts, saving you maintenance costs and downtime. With a global supply chain, we ensure fast, reliable delivery no matter where you are.

Comparison Table: Nickel Alloy C-276 Coil vs. Other Alloys

|

Property/Feature |

Nickel Alloy C-276 |

Inconel 625 |

Stainless Steel 316L |

|---|---|---|---|

|

Nickel Content (%) |

~57 |

~61 |

~10-14 |

|

Molybdenum Content (%) |

15-17 |

8-10 |

2-3 |

|

Chromium Content (%) |

14.5-16.5 |

20-23 |

16-18 |

|

Tensile Strength (ksi) |

110 min |

120 min |

70-85 |

|

Yield Strength (ksi) |

52 min |

60 min |

25-40 |

|

Corrosion Resistance |

Superior in acids and chlorides |

Strong in high-temp oxidation |

Moderate, weaker in chlorides |

|

Temperature Resistance |

Up to 1900°F (1038°C) |

Up to 1800°F (982°C) |

Up to 1600°F (871°C) |

|

Weldability |

Excellent, low carbon |

Good, needs careful handling |

Good, but less resistant post-weld |

|

Applications |

Chemical, oil/gas, pharma |

Aerospace, high-temp uses |

General industrial use |

Industry Analysis

Our Nickel Alloy C-276 coil is built to tackle the toughest challenges in industries like chemical processing, oil and gas, power generation, pharmaceuticals, and marine engineering. Its nickel-molybdenum-chromium composition delivers unmatched corrosion resistance, high-temperature stability, and durability, making it perfect for harsh environments. With industry trends leaning toward sustainability and long-lasting materials, our coil is a smart choice that reduces costs and boosts efficiency.

We take pride in offering a product that’s not just tough but also easy to work with. Our commitment to quality, customization, and support sets us apart. From rigorous quality control to global delivery, we’ve got everything you need to make your project a success. Choose our Nickel Alloy C-276 coil for a material that stands up to the harshest conditions and a company that’s all about getting it right.

For more details, pls directly contact us.

|

|

|

|

|

|

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the composition of Nickel Alloy C-276 coil?

It’s a nickel-based alloy with ~57% nickel, 15-17% molybdenum, 14.5-წSystem: 16.5% chromium, 3-4.5% tungsten, 4-7% iron, and trace elements like cobalt and carbon.

-

What industries rely on Nickel Alloy C-276 coil?

Chemical processing, oil and gas, pharmaceuticals, power generation, marine engineering, and pollution control. -

What are its primary applications?

Used in chemical reactors, heat exchangers, piping systems, scrubbers, and offshore platform components. -

How does it perform against corrosion?

Exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in acidic and chloride-rich environments. -

Is Nickel Alloy C-276 coil easy to weld?

Yes, it welds well with TIG, MIG, or shielded metal-arc methods, thanks to low carbon content that prevents cracking. -

What temperatures can it handle?

It maintains strength and corrosion resistance up to 1900°F (1038°C), ideal for high-heat applications. -

Is it cost-effective compared to other materials?

Higher upfront cost but saves money long-term due to durability and low maintenance needs. -

What standards does it meet?

Meets ASTM B575, ASME, and UNS N10276 standards for consistent quality and performance.