Durable Incoloy 800H Plate for Creep-Resistant Industrial Applications

Our Incoloy 800 H plate is built to deliver unbeatable creep resistance and high-temperature strength, keeping industrial components like furnace parts and reactors running strong in the toughest conditions. This isn’t just metal—it’s a rugged, reliable solution for industries battling extreme heat and stress. Let’s dive into what makes our Incoloy 800H plate a top choice, from its tough materials to its critical applications, while exploring industry trends and why our company stands out as the go-to for creep-resistant solutions.

For more details, pls directly contact us.

We craft our Incoloy 800H plate from a high-performance alloy of 30-35% nickel, 19-23% chromium, iron, with controlled carbon (0.05-0.10%), and aluminum/titanium additions for enhanced durability. The nickel and chromium form a stable oxide layer that fights oxidation and carburization up to 1500°F (816°C), while the controlled carbon boosts creep resistance for long-term performance under thermal stress. Available in thicknesses from 0.1875″ (4.8mm) to 2.00″ (50.8mm), it’s designed for easy forming and welding, meeting standards like ASTM B409 and ASME SB 409. Our rigorous testing ensures purity and consistency, delivering plates that resist scaling, creep, and thermal fatigue, lasting 3-5 years in demanding industrial environments. This makes it perfect for petrochemical, power generation, and industrial furnace applications.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

In industrial applications, our Incoloy 800H plate is a powerhouse. It’s used in furnace components like radiant tubes, resisting oxidation and creep in high-heat steel and glass production. Petrochemical reactors rely on it to handle carburization from hydrocarbon processing, extending equipment life. Steam generator tubing benefits from its ability to withstand high-pressure steam at 1500°F (816°C) without cracking. Heat exchangers use it to maintain structural integrity under prolonged heat exposure. We’ve seen it applied in nuclear power plants, resisting carburization in reactor environments, and in fossil fuel plants, handling coal combustion byproducts. Its weldability makes it ideal for fabricating complex assemblies, ensuring robust performance in high-temperature systems.

Comparison Parameters Table for Incoloy 800H vs Incoloy 825 Plate

| Parameter | Incoloy 800H Plate | Incoloy 825 Plate |

|---|---|---|

| Composition | Ni (30-35%), Cr (19-23%), Fe, 0.05-0.10% C, Al/Ti | Ni (38-46%), Cr (19.5-23.5%), Fe, Mo, Cu, Ti |

| Creep Resistance | Superior; controlled carbon enhances strength for long-term high-temperature use | Moderate; focuses more on corrosion than creep resistance |

| Oxidation Resistance | Excellent; resists scaling up to 1500°F (816°C) in high-heat environments | Good; effective up to 1000°F (538°C) but less suited for extreme heat |

| Temperature Tolerance | Up to 1500°F (816°C); ideal for furnaces and reactors | Up to 1000°F (538°C); better for corrosive, less extreme heat environments |

| Cost | Moderate; cost-effective for high-temperature applications | Higher; premium for enhanced corrosion resistance |

| Corrosion Resistance | Good; resists oxidation and carburization but less effective in chloride environments | Excellent; superior resistance to chloride pitting and acidic media |

| Application Suitability | Furnace components, reactors, steam generators; excels in high-heat settings | Pipelines, heat exchangers; better for corrosive chemical environments |

| Durability | High; withstands 3-5 years in high-temperature industrial conditions | High; excels in corrosive settings but less in extreme heat |

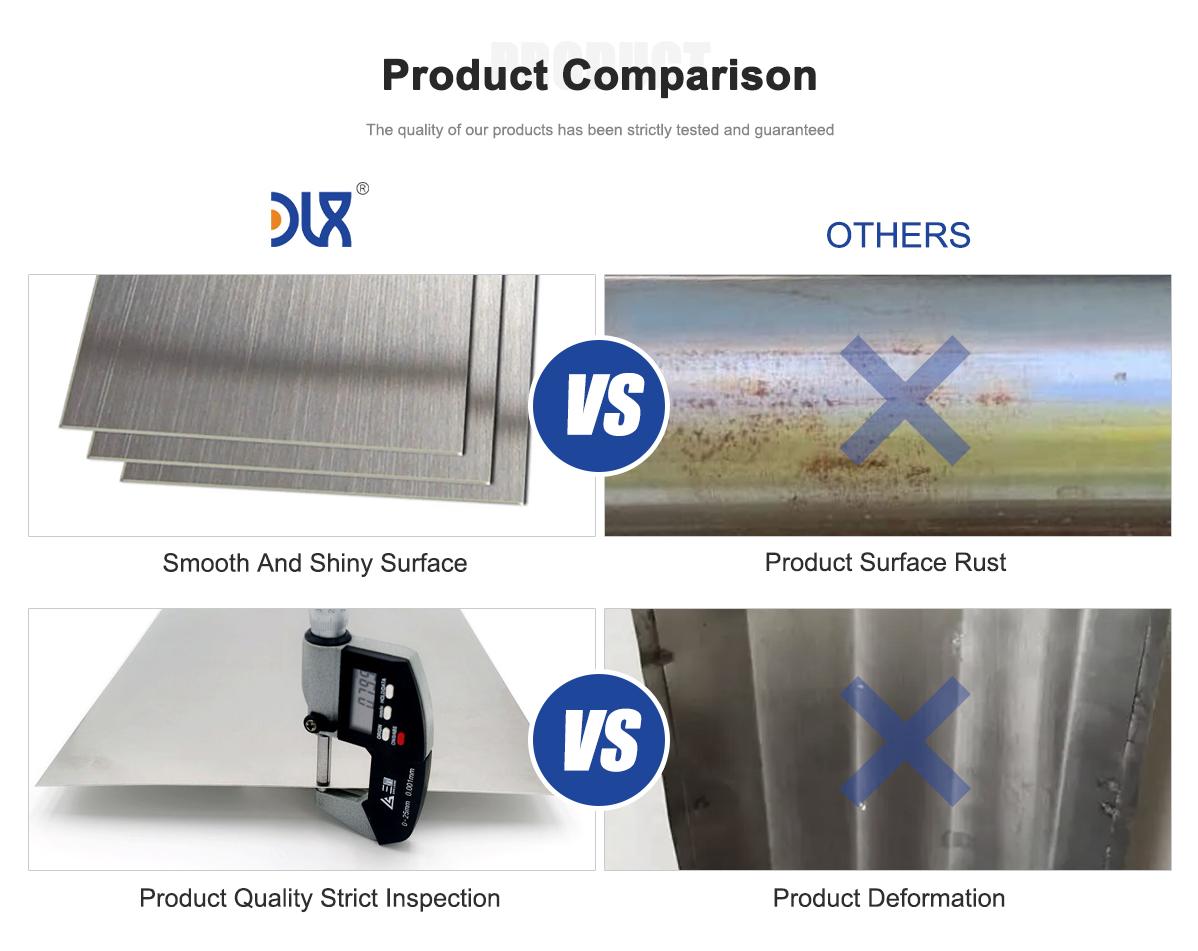

| Surface Finish | Smooth, stable oxide layer for high-temperature durability | Smooth, low-porosity surface for corrosion resistance |

| Process Compatibility | Readily formable, weldable for furnace and reactor fabrication | Formable, weldable but optimized for corrosive environments |

The high-temperature alloy market is red-hot, and our Incoloy 800H plate is leading the charge. The global market for nickel-based alloys is growing at a CAGR of 6-7%, projected to hit billions by 2032, driven by rising demand for industrial furnaces and power generation systems. Components in these settings face extreme heat and stress, and our plate delivers long-lasting creep resistance to cut maintenance costs. Sustainability is a big focus—industries want eco-friendly materials, and our recyclable alloy, paired with green manufacturing powered by renewable energy, fits perfectly.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials are used in Incoloy 800H plate?

Nickel (30-35%), chromium (19-23%), iron, controlled carbon (0.05-0.10%), aluminum, and titanium for creep resistance and high-temperature strength.

What are the primary applications of Incoloy 800H plate in industrial settings?

Used in furnace components, petrochemical reactors, steam generator tubing, and heat exchangers to resist creep and oxidation.

How does Incoloy 800H plate provide creep resistance?

Controlled carbon and aluminum/titanium enhance structural stability, while nickel and chromium resist oxidation up to 1500°F (816°C).

What industry trends are driving demand for Incoloy 800H plate?

Rising industrial furnace use, 6-7% CAGR market growth through 2032, sustainable material demands, and advancements in high-temperature alloys.

Is Incoloy 800H plate suitable for high-temperature industrial environments?

Yes, it withstands temperatures up to 1500°F (816°C), resisting creep, oxidation, and thermal fatigue in harsh conditions.

How do you maintain Incoloy 800H plate components?

Inspect every 12-18 months for scaling or creep, clean deposits, and replace or recoat every 3-5 years as needed.

How do environmental factors affect Incoloy 800H plate performance?

Resists oxidation and carburization in high-heat environments but may need monitoring in sulfur-rich conditions.

What future trends might impact Incoloy 800H plate for industrial applications?

Nanotechnology-enhanced alloys, use in renewable energy systems, and eco-friendly production to reduce environmental impact.