Incoloy 800 Plate for Heat-Treating Equipment High-Temperature Strength

Our Incoloy 800 plate is a game-changer for industries needing materials that can handle scorching temperatures and tough conditions. This nickel-iron-chromium alloy is built for strength, resisting oxidation and carburization even when the heat is on. It’s perfect for heat-treating equipment, staying tough and reliable up to 1500°F (816°C). With excellent resistance to chloride stress-corrosion cracking and no embrittling sigma phase after long-term exposure at 1200°F (649°C), our Incoloy 800 plate ensures your equipment lasts longer and performs better. Whether it’s for furnace components, petrochemical processing, or power generation, this alloy delivers top-notch performance where it counts.

For more details, pls directly contact us.

The demand for high-temperature alloys like Incoloy 800 is skyrocketing as industries push for efficiency in extreme environments. Petrochemical, power generation, and aerospace sectors are driving growth, with the global high-temperature alloy market expected to grow steadily through 2030, fueled by rising energy demands and stricter environmental regulations. Trends show a shift toward materials that can withstand higher temperatures and corrosive conditions while maintaining structural integrity. Our Incoloy 800 plate fits right into this, offering a cost-effective solution for applications requiring long-term durability. As industries adopt cleaner technologies, like advanced heat exchangers and nuclear reactors, alloys like ours are becoming critical for sustainable, high-performance operations.

Parameter | Our Incoloy 800 Plate | Competitor’s Alloy Plate |

|---|---|---|

Nickel Content | 30-35% for optimal corrosion resistance | Often lower, reducing durability |

Temperature Range | Up to 1500°F (816°C) with excellent stability | Limited to lower temperatures |

Creep Resistance | High, ideal for long-term high-heat exposure | Moderate, less suited for prolonged use |

Corrosion Resistance | Excellent against oxidation and carburization | Good but may degrade in harsh environments |

Weldability | Easy with standard methods, no post-weld issues | May require special handling |

Customization | Tailored sizes, finishes, and quick turnaround | Limited options, longer lead times |

Standards Compliance | ASTM B409, B408, ASME Code Case 1325 | May not meet all industry standards |

Delivery Time | Fast, global supply chain | Slower, less reliable logistics |

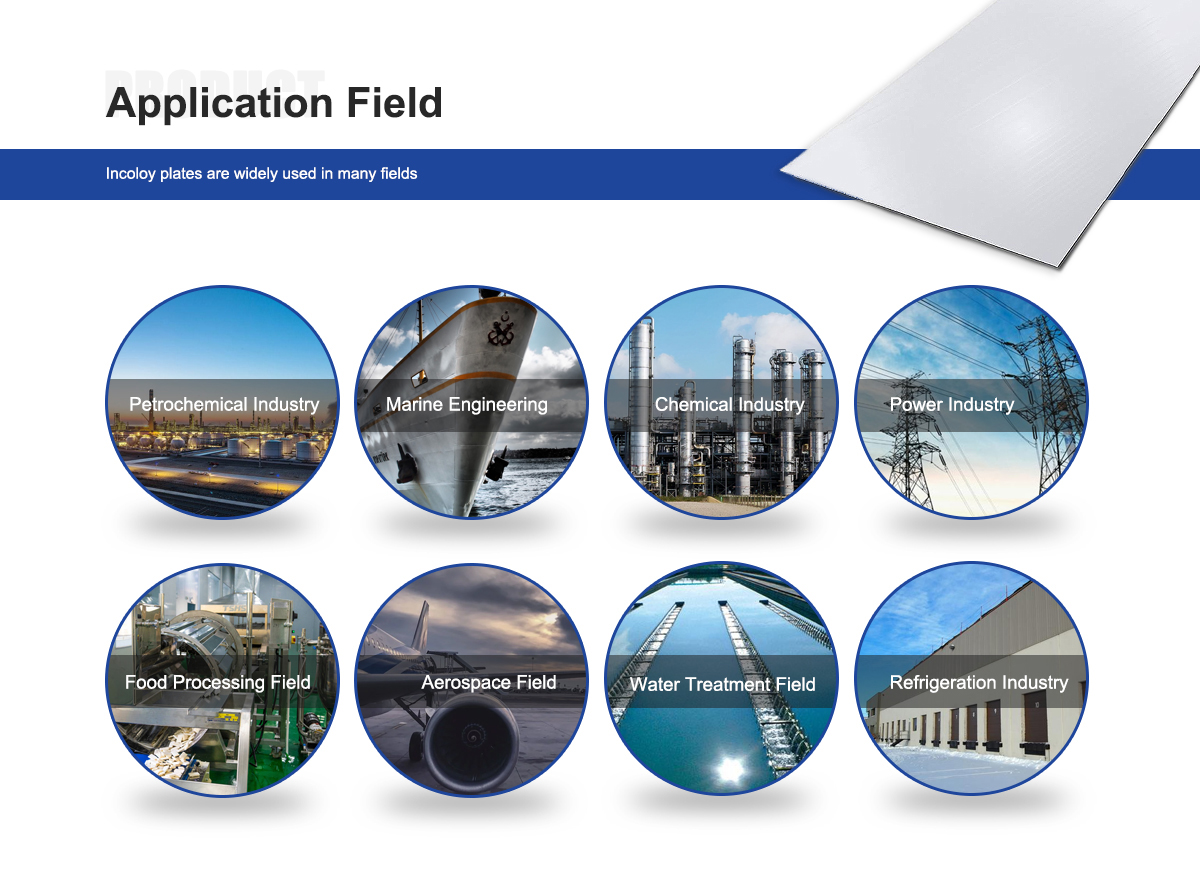

Our Incoloy 800 plate shines in environments where heat and corrosion are relentless. It’s widely used in:

Heat-Treating Equipment: Baskets, trays, and fixtures that endure high-temperature cycles.

Petrochemical Processing: Heat exchangers, reactors, and piping for ethylene and nitric acid production.

Power Generation: Superheater and reheater tubing in coal and nuclear plants.

Chemical Processing: Components handling aggressive chemicals at elevated temperatures.

Aerospace: Parts exposed to high heat during flight, ensuring reliability under stress. Its versatility makes it a go-to for industries needing materials that won’t crack under pressure—literally.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

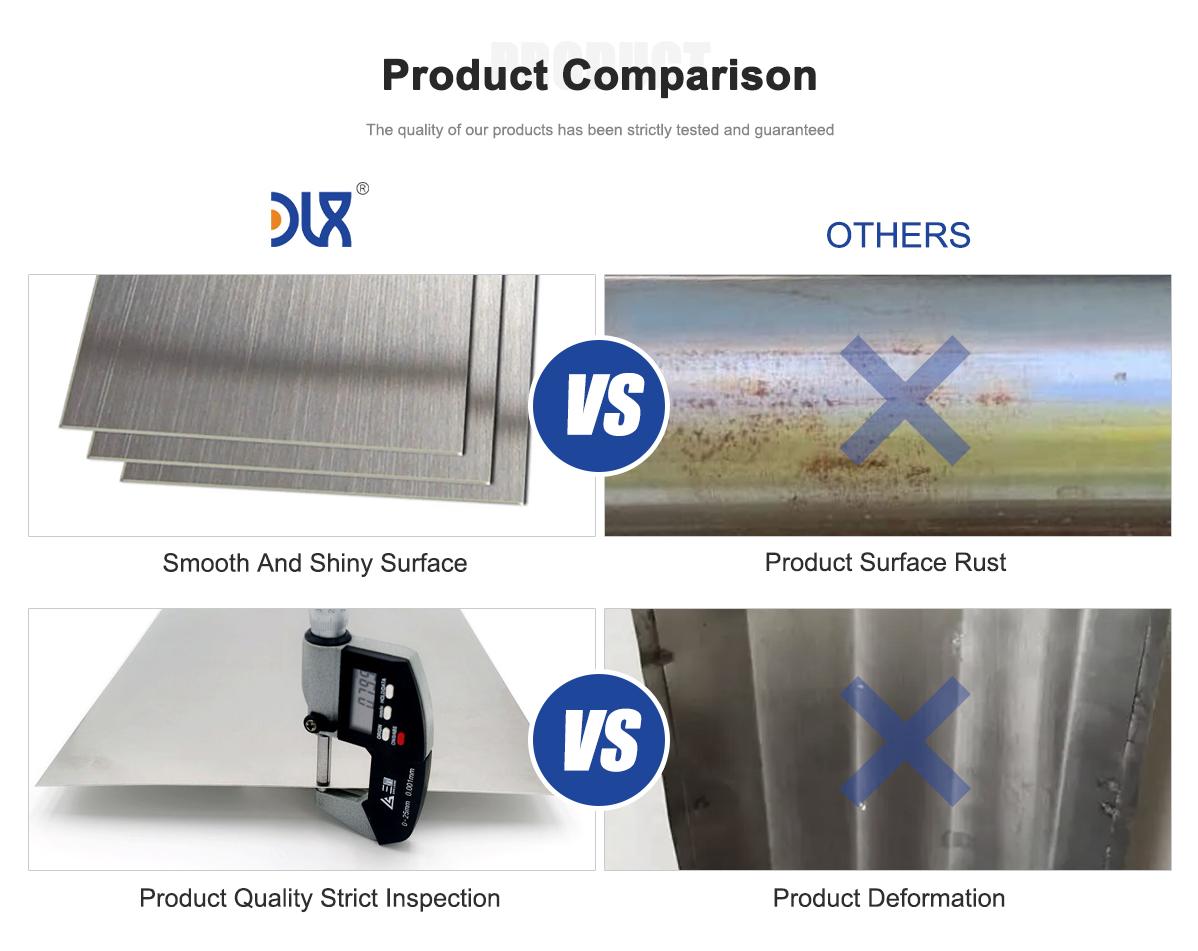

When you’re choosing an Incoloy 800 plate, you want a supplier that stands out. Our company delivers plates with tighter tolerances and stricter quality control, ensuring consistent performance in high-stakes applications. We offer customized sizes and finishes, tailored to your exact needs, without the long lead times others might hit you with. Our in-house testing guarantees every plate meets ASTM standards (B409, B408), and we provide full chemical and mechanical certifications for transparency. Plus, our global supply chain means faster delivery and competitive pricing, keeping your projects on track and on budget.

Why Choose Our Incoloy 800 Plate?

Superior Quality: Rigorous testing ensures top-tier resistance to oxidation and creep.

Customization: Cut-to-size plates and tailored finishes for seamless integration.

Fast Delivery: Streamlined logistics to keep your operations running smoothly.

Cost-Effective: High durability reduces maintenance and replacement costs.

Expert Support: Our team helps you pick the perfect specs for your project.

About Us:

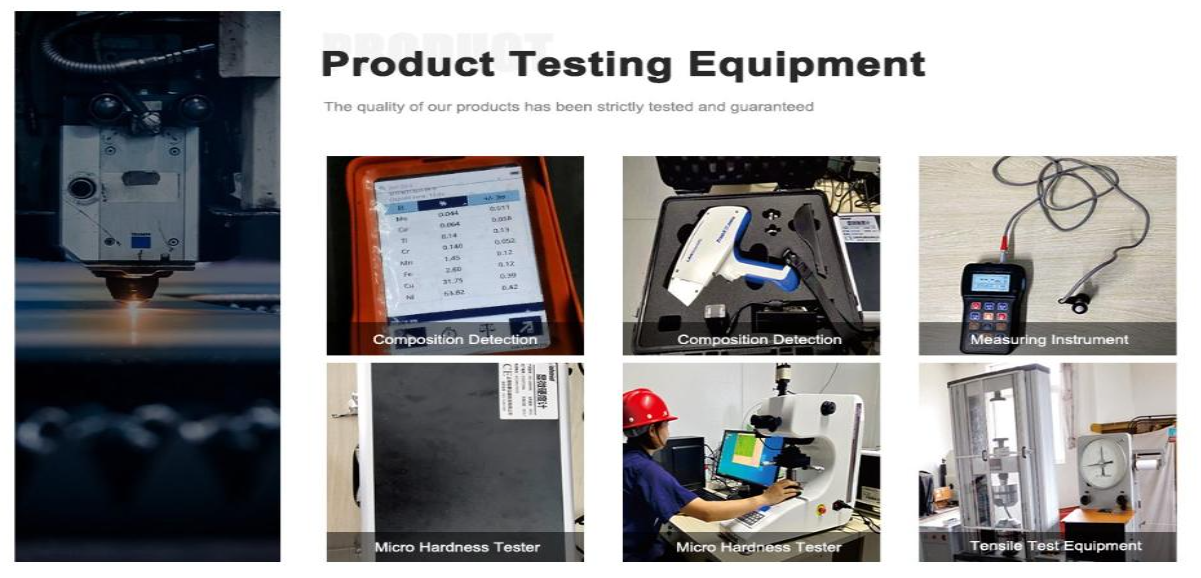

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Incoloy 800 ideal for heat-treating equipment?

Its high-temperature strength and resistance to oxidation and carburization ensure durability in furnaces and heat-treating setups.Can Incoloy 800 handle corrosive environments?

Absolutely, it resists chloride stress-corrosion cracking and performs well in acidic and chemical-heavy settings.What temperatures can Incoloy 800 withstand?

It’s reliable up to 1500°F (816°C) for continuous use, perfect for high-heat applications.Is Incoloy 800 weldable?

Yes, it welds easily with standard techniques like TIG and MIG, maintaining strength post-welding.What industries use Incoloy 800 plates?

Petrochemical, power generation, aerospace, and chemical processing rely on it for critical components.How does Incoloy 800 compare to stainless steel?

It offers better high-temperature strength and corrosion resistance than most stainless steels, especially in extreme conditions.Does Incoloy 800 require special heat treatment?

It’s typically used in the annealed condition, but solution annealing may be needed after heavy cold working.What standards does Incoloy 800 meet?

Our plates comply with ASTM B409, B408, and ASME codes for quality and reliability.