Incoloy 925 Plate: Corrosion-Resistant Solution for Oil and Gas Applications

Our Incoloy 925 plate is built to tackle the brutal conditions of oil and gas applications, delivering top-notch corrosion resistance to keep critical components like wellhead equipment and pipelines running strong. This isn’t just metal—it’s a tough, reliable solution for the harshest environments in the industry. Let’s dive into what makes our Incoloy 925 plate a standout, from its robust materials to its critical applications, while exploring industry trends and why our company is the go-to for oil and gas durability.

We craft our Incoloy 925 plate from a high-performance alloy of 42-46% nickel, 19.5-22.5% chromium, iron, with molybdenum, copper, titanium, and aluminum for exceptional corrosion and stress resistance. The high nickel and molybdenum content fights pitting and crevice corrosion in chloride-rich seawater and sour gas, while titanium and aluminum enhance strength and resistance to sulfide stress cracking. Available in thicknesses from 0.1875″ (4.8mm) to 2.00″ (50.8mm), it’s designed for easy forming and welding, meeting standards like ASTM B424 and ASME SB 424. Our rigorous testing ensures purity and consistency, delivering plates that resist corrosion, stress cracking, and temperatures up to 1000°F (538°C), lasting 3-5 years in harsh oil and gas settings. This makes it perfect for offshore platforms, downhole operations, and chemical processing tied to oil and gas.

For more details, pls directly contact us.

In oil and gas applications, our Incoloy 925 plate is a workhorse. It’s used in wellhead equipment, resisting corrosion from sour gas and high-pressure fluids. Pipelines rely on it to handle chloride-rich seawater and acidic media without pitting or cracking. Valves and fittings benefit from its strength, standing up to sulfide stress cracking in deep-sea environments. Downhole components use it to withstand corrosive drilling fluids and high mechanical stress. We’ve seen it applied in offshore risers, handling seawater corrosion, and in LNG processing equipment, resisting acidic byproducts. Its weldability makes it ideal for fabricating robust assemblies, ensuring reliable performance in high-pressure, corrosive environments like subsea and Arctic operations.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

The corrosion-resistant alloy market is booming, and our Incoloy 925 plate is at the forefront. The global market for nickel-based alloys is growing at a CAGR of 6-7%, projected to hit billions by 2032, driven by rising offshore exploration and energy demands. Oil and gas components face harsh conditions—sour gas, seawater, and high pressure—so materials must be tough and reliable. Our plate delivers durability that extends component life, cutting maintenance costs. Sustainability is a big focus—operators want eco-friendly materials, and our recyclable alloy, paired with green manufacturing powered by renewable energy, fits the bill. Advancements in alloy fabrication, like wire arc additive manufacturing, are improving plate precision, and our Incoloy 925 is optimized for these processes. Regulatory bodies like NACE MR0175 approve our alloy for sour gas service, ensuring compliance. Supply chain challenges, like nickel price volatility, are real, but our diversified sourcing keeps us steady. The rise of deep-sea exploration and renewable energy systems, like geothermal platforms, is opening new markets where corrosion resistance is critical.

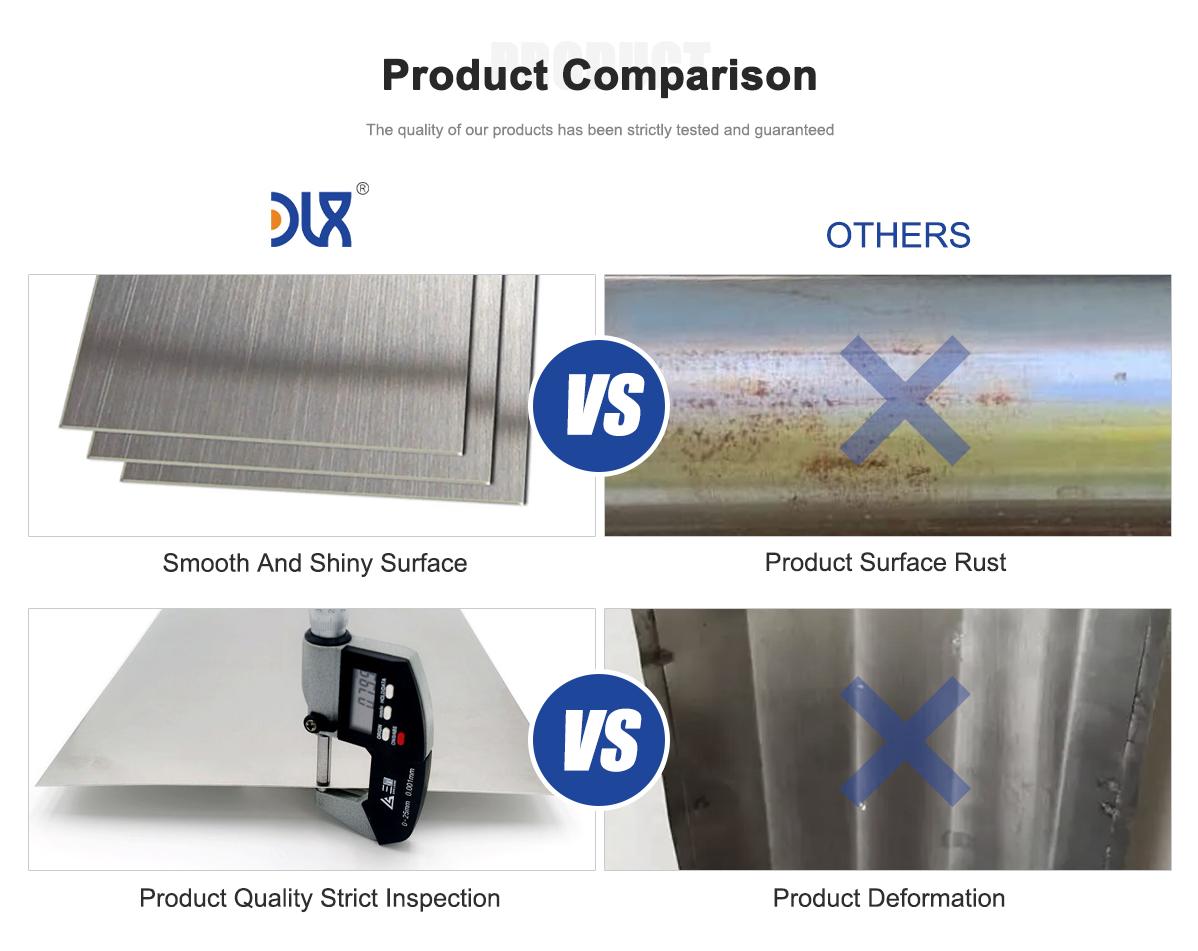

What sets our company apart? It’s our relentless focus on quality, customization, and innovation. We don’t just churn out plates; we tailor solutions for your oil and gas needs. Our R&D team optimizes the Incoloy 925 alloy for maximum corrosion and stress resistance, outperforming standard options in harsh environments. Need custom thicknesses or sizes for your platform? We hit tolerances tighter than industry norms, ensuring precise, defect-free plates. Our quality control is rigorous—testing for corrosion resistance, stress cracking, and weldability in simulated sour gas and seawater conditions. We deliver fast, with streamlined production cutting lead times, so your projects stay on schedule. Our eco-friendly manufacturing appeals to clients chasing green certifications, giving us a clear edge in reliability and sustainability.

Let’s zoom in on applications. Our Incoloy 925 plate is a lifesaver for wellhead equipment, resisting corrosion and stress cracking in sour gas environments. Pipelines rely on it to handle seawater and acidic fluids without pitting, ensuring reliable transport. Valves benefit from its high strength, standing up to high-pressure, corrosive conditions. In downhole operations, it protects components from drilling fluids and mechanical stress. We’ve optimized it for fabrication, with excellent weldability for building robust assemblies. It’s also used in subsea risers, resisting seawater corrosion, and in LNG processing, handling acidic byproducts without degrading. The plate’s versatility makes it ideal for both upstream and downstream oil and gas applications.

Industry trends are exciting. The push for net-zero emissions is driving demand for materials that extend equipment life, reducing replacements. North America and Asia-Pacific lead in offshore exploration, but Europe is investing in sustainable energy platforms. Economic pressures, like molybdenum price fluctuations, challenge the market, but our efficient processes keep costs competitive. Post-COVID, supply chain resilience is critical, and our global facilities ensure steady delivery. Innovations like nanotechnology-enhanced coatings for added durability are emerging, and we’re exploring those to stay ahead. The growth of deep-sea and Arctic exploration increases demand for corrosion-resistant materials, and our plate is ready to deliver.

Our company’s strength lies in comprehensive support. We offer application guidance, from fabrication techniques to maintenance schedules, ensuring optimal performance. Our testing labs simulate oil and gas conditions—sour gas, seawater, high pressure—proving our plates last longer with minimal degradation. Compared to typical market options, our Incoloy 925 plate offers superior resistance to sulfide stress cracking and chloride pitting, reducing maintenance frequency. We provide value-added services like custom cutting and pre-fabricated components, building long-term partnerships with clients who value reliability and savings.

Comparison Parameters Table for Incoloy 925 vs Incoloy 825 Plate

| Parameter | Incoloy 925 Plate | Incoloy 825 Plate |

|---|---|---|

| Composition | Ni (42-46%), Cr (19.5-22.5%), Fe, Mo, Cu, Ti, Al | Ni (38-46%), Cr (19.5-23.5%), Fe, Mo, Cu, Ti |

| Corrosion Resistance | Excellent; superior resistance to sulfide stress cracking and chloride pitting | Excellent; strong resistance to chloride pitting and acidic media |

| Strength | High; enhanced by Ti/Al for stress-corrosion resistance in sour gas | Moderate; focuses on corrosion over high mechanical strength |

| Temperature Tolerance | Up to 1000°F (538°C); ideal for oil and gas corrosive environments | Up to 1000°F (538°C); suited for chemical and offshore applications |

| Cost | Higher; premium for high strength and corrosion resistance | Moderate; cost-effective for general corrosion resistance |

| Stress Resistance | Superior; resists sulfide stress cracking in high-pressure sour gas settings | Good; less effective in extreme stress-corrosion conditions |

| Application Suitability | Wellhead equipment, downhole components; excels in sour gas environments | Pipelines, heat exchangers; better for general chemical corrosion |

| Durability | High; withstands 3-5 years in harsh oil and gas conditions | High; withstands 3-5 years in corrosive but less mechanically stressed settings |

| Surface Finish | Smooth, low-porosity surface for corrosion and stress resistance | Smooth, low-porosity surface for corrosion resistance |

| Process Compatibility | Readily formable, weldable for oil and gas fabrication | Formable, weldable but optimized for less mechanically demanding environments |

Product-wise, our Incoloy 925 plate is designed for corrosion resistance, with a composition optimized for sour gas and seawater environments. The high nickel, molybdenum, and copper content ensures resistance to pitting and crevice corrosion, while titanium and aluminum enhance strength. It’s available in a range of thicknesses for seamless integration into oil and gas fabrication, delivering smooth, low-porosity surfaces for maximum durability. The alloy’s mechanical properties remain strong from cryogenic to 1000°F (538°C), making it versatile for offshore and onshore applications.

Looking ahead, trends like smart coatings with sensors for real-time corrosion monitoring are gaining traction. Regulatory shifts toward sustainable oil and gas operations align with our strengths, as our plate extends equipment life. The growth of renewable energy platforms, like geothermal systems, increases demand for corrosion-resistant materials, and we’re positioned to lead. We’re also investing in greener alloy production to cut our carbon footprint, appealing to eco-conscious operators.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials are used in Incoloy 925 plate?

Nickel (42-46%), chromium (19.5-22.5%), iron, molybdenum, copper, titanium, and aluminum for corrosion and stress resistance.

What are the primary applications of Incoloy 925 plate in oil and gas?

Used in wellhead equipment, pipelines, valves, and downhole components to resist corrosion and stress in harsh oil and gas environments.

How does Incoloy 925 plate provide corrosion resistance?

High nickel, molybdenum, and copper content resists pitting, crevice corrosion, and sulfide stress cracking in sour gas and seawater.

What industry trends are driving demand for Incoloy 925 plate?

Rising offshore exploration, 6-7% CAGR market growth through 2032, sustainable material demands, and advancements in corrosion-resistant alloys.

Is Incoloy 925 plate suitable for harsh oil and gas environments?

Yes, it withstands sour gas, chloride-rich seawater, and temperatures up to 1000°F (538°C) in demanding conditions.

How do you maintain Incoloy 925 plate components?

Inspect every 12-18 months for pitting or cracking, clean off deposits, and replace or recoat every 3-5 years as needed.

How do environmental factors affect Incoloy 925 plate performance?

Resists chloride and H2S corrosion but may need monitoring in high-fluoride or extreme acidic environments.

What future trends might impact Incoloy 925 plate for oil and gas applications?

Nanotechnology-enhanced coatings, use in deep-sea and renewable energy systems, and eco-friendly alloy production to reduce environmental impact.