Incoloy 800 Tube: High-Temperature Resistance for Petrochemical and Furnace Applications

When it comes to materials that are designed to thrive in extreme conditions, Incoloy 800 tube is one of the most reliable choices available today. Engineered as a nickel-iron-chromium alloy, this product has gained widespread recognition across industries that require exceptional stability at elevated temperatures. Whether it is petrochemical refining, furnace equipment, or high-demand heat processing environments, the Incoloy 800 tube is consistently chosen because of its unique blend of strength, oxidation resistance, and longevity.

Our company has dedicated years of expertise to perfecting the production and supply of Incoloy 800 tubes. We not only manufacture according to international standards, but also tailor specifications to meet the diverse needs of clients worldwide. With in-house expertise, advanced production facilities, and strict quality controls, we ensure that our Incoloy 800 tubes exceed expectations in both performance and reliability.

For more details, pls directly contact us.

Incoloy 800 is designed around a balanced composition of nickel, iron, and chromium. Nickel provides high resistance to carburization and oxidation, while chromium enhances scaling resistance in high-temperature atmospheres. Iron stabilizes the alloy, making it both cost-effective and structurally sound.

The alloy is engineered to perform under long-term exposure to elevated temperatures without losing mechanical strength. In environments where other metals may soften or fail due to creep, Incoloy 800 retains its shape and load-bearing capacity. Its metallurgical stability is one of the primary reasons why it is trusted for petrochemical heaters and industrial furnaces.

Applications in Key Industries

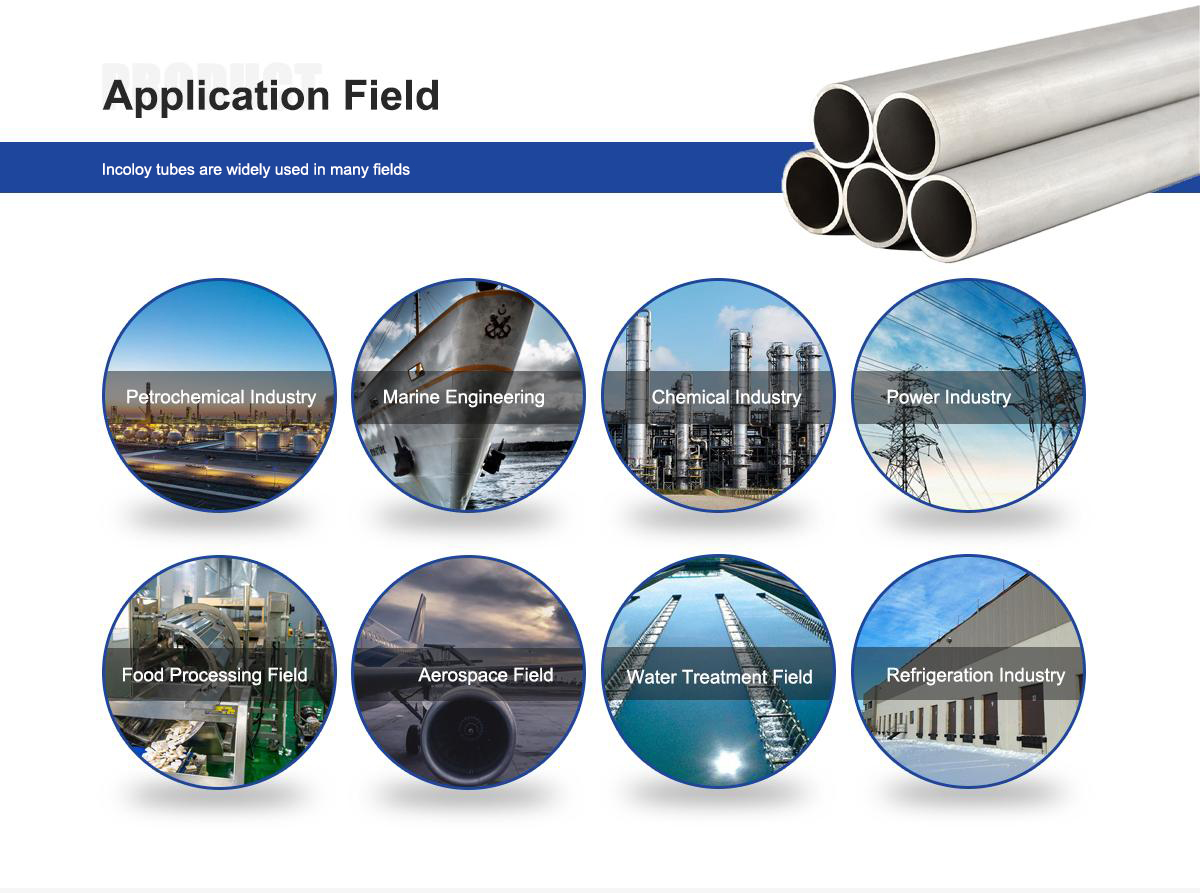

Petrochemical processing plants are among the biggest users of Incoloy 800 tubes. Equipment like ethylene furnace tubes, hydrocarbon cracking units, and heat exchangers require materials that can withstand aggressive atmospheres and long-term thermal cycling. Incoloy 800 meets these challenges by resisting carburization from hydrocarbons and maintaining structural integrity even when exposed to hydrogen-rich environments.

Furnace manufacturers also rely on this alloy for radiant tubes, muffles, and structural components. Since furnaces operate continuously at high temperatures, the tubes must resist scaling and distortion. Incoloy 800 ensures efficiency by reducing downtime caused by material failures and minimizing replacement costs.

The alloy’s role is not limited to heavy industries. It also finds use in power generation, nuclear steam generators, and heat treatment plants. In all these sectors, consistent thermal performance is essential, and Incoloy 800 tube offers precisely that.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

The global demand for high-temperature alloys is on the rise. With growing investments in petrochemical infrastructure, renewable energy systems, and advanced furnace technologies, materials like Incoloy 800 are experiencing increased demand. Many countries are upgrading their refining capacities, and this trend is directly pushing the need for durable, high-performance alloys.

Sustainability is another important factor shaping industry preferences. Long-lasting materials reduce waste, minimize downtime, and enhance efficiency, all of which contribute to more sustainable operations. Incoloy 800 tubes, with their proven service life, align perfectly with this trend.

In addition, global safety standards are becoming more stringent. Operators are increasingly seeking materials that can deliver predictable performance under stress. The ability of Incoloy 800 to resist creep rupture and maintain structural stability ensures that it complies with evolving safety and reliability requirements.

Comparison with Alternatives

When compared with stainless steels, Incoloy 800 offers significantly higher performance at elevated temperatures. Stainless steel 310, for example, is often used in high-temperature settings but lacks the same level of carburization resistance. Incoloy 800, by contrast, ensures longer service life in aggressive chemical and heat environments.

Compared to Inconel 600, another nickel-chromium alloy, Incoloy 800 is more cost-effective while still providing excellent resistance to oxidation and carburization. This balance of affordability and performance is one of the reasons Incoloy 800 remains a widely adopted choice.

Customization and Supply Capabilities

One of the strengths of our company lies in our ability to customize Incoloy 800 tubes according to specific project needs. Clients often require unique wall thicknesses, lengths, and diameters to suit specialized equipment. We provide tailored solutions without compromising on metallurgical integrity.

We also ensure timely delivery, which is critical in industries where equipment downtime can result in substantial financial losses. By maintaining a well-structured supply chain and stocking standard sizes, we enable customers to receive materials promptly while still having the flexibility to request customized production runs.

Comparison Table: Incoloy 800 Tube vs Common Alternatives

| Property | Incoloy 800 Tube | Stainless Steel 310 Tube | Inconel 600 Tube |

|---|---|---|---|

| Base Composition | Nickel-Iron-Chromium | Iron-Chromium-Nickel | Nickel-Chromium |

| Max Service Temp | ~1100°C (2000°F) | ~1050°C (1920°F) | ~1150°C (2100°F) |

| Oxidation Resistance | Excellent | Good | Excellent |

| Carburization Resistance | Excellent | Moderate | Excellent |

| Creep Strength | High | Medium | Very High |

| Weldability | Good | Good | Good |

| Cost | Moderate-High | Moderate | Higher |

| Typical Applications | Petrochemical, furnaces, heaters | Heat exchangers, kilns | Aerospace, chemical reactors |

As industries continue to evolve, the demand for high-performance alloys like Incoloy 800 will only grow stronger. With innovations in petrochemical processing, expansion of renewable energy infrastructure, and stricter requirements for reliability, the role of high-temperature materials will become even more vital.

Our company is committed to staying ahead of these trends by investing in advanced production methods and expanding our technical support capabilities. By doing so, we ensure that our Incoloy 800 tubes remain not just relevant, but indispensable in the modern industrial landscape.

Conclusion

Incoloy 800 tubes stand out as a trusted solution for high-temperature applications in petrochemical plants, furnaces, and beyond. Their combination of nickel, iron, and chromium ensures stability, resistance to aggressive atmospheres, and longevity in service. With growing global demand for reliable high-temperature alloys, choosing a supplier with proven expertise is more important than ever.

Our company offers more than just tubes—we provide assurance of performance, reliability, and long-term value. Through consistent quality, technical support, and adaptability, we continue to be a preferred partner for industries that operate in the toughest conditions. Incoloy 800 is not just a material; it’s a guarantee of durability and efficiency, and we are proud to deliver it to clients worldwide.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the primary material composition of Incoloy 800 tube?

Nickel-iron-chromium alloy with balanced additions for strength and oxidation resistance.What temperature range can Incoloy 800 tubes handle?

Typically up to 1100°C (2000°F).Which industries commonly use Incoloy 800 tubes?

Petrochemical, power generation, furnace manufacturing, and heat treatment industries.How does Incoloy 800 perform against carburization and oxidation?

Excellent resistance under high-temperature and reducing environments.Is Incoloy 800 tube weldable?

Yes, it offers good weldability with standard welding methods.What are the main benefits of using Incoloy 800 tube in furnace applications?

High thermal stability, long service life, and resistance to scaling.How does Incoloy 800 compare to stainless steel in high-temperature conditions?

It maintains strength and resists creep much better at elevated temperatures.Can Incoloy 800 be customized in size and shape for different projects?

Yes, tubes can be manufactured in various sizes, wall thicknesses, and lengths.