Incoloy 800HT Tube: Superior Creep Resistance for High-Temperature Power Generation

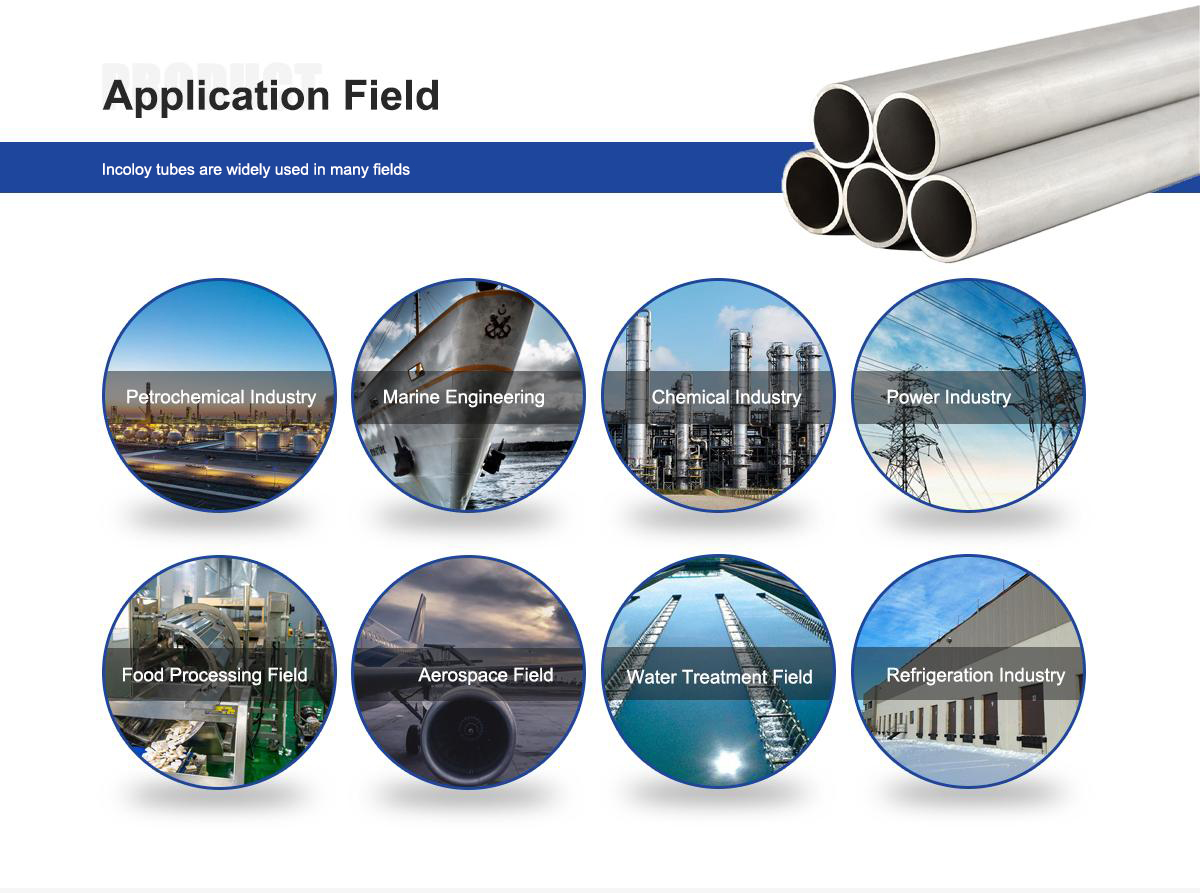

High-temperature industrial environments demand materials that can withstand constant stress, aggressive atmospheres, and long-term exposure to heat. One alloy that stands out in this regard is the Incoloy 800 HT tube. Engineered to deliver superior creep resistance and exceptional mechanical stability, this material has become a cornerstone in industries like power generation, petrochemical refining, and high-performance furnace construction.

Our company has spent years mastering the production and supply of Incoloy 800HT tubes. Through advanced metallurgical control, precision manufacturing, and strict quality testing, we deliver tubes that consistently outperform expectations. In environments where other materials fail due to creep, distortion, or corrosion, our Incoloy 800HT tubes continue to perform reliably, making them a trusted choice for global clients.

For more details, pls directly contact us.

Incoloy 800HT is a nickel-iron-chromium alloy that builds on the foundation of Incoloy 800 but with key enhancements. It contains carefully controlled amounts of carbon, aluminum, and titanium. These modifications strengthen the alloy’s microstructure, giving it outstanding creep rupture properties at high temperatures.

Creep resistance is crucial in industries like power generation where tubes are exposed to constant stress at elevated temperatures for thousands of hours. Standard alloys may lose strength over time, but Incoloy 800HT maintains its load-bearing capacity, ensuring safe and efficient operation of equipment.

The alloy also provides excellent resistance to oxidation, carburization, and chloride-induced stress cracking. This makes it versatile in environments where both chemical and thermal stability are essential.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

The power industry requires materials that can deliver uninterrupted performance. Boilers, superheaters, and turbine components all operate under extreme conditions, often close to 1100°C. Incoloy 800HT tubes are widely used in these systems because of their ability to resist creep deformation, maintain structural stability, and extend service life.

In fossil-fuel power plants, superheater and reheater tubes face high temperatures and pressures, along with the risk of oxidation and scaling. Incoloy 800HT offers the durability needed to maintain efficiency over long operational cycles.

In nuclear power systems, Incoloy 800HT tubes play a critical role in heat exchangers and steam generator tubing. Their metallurgical stability ensures consistent performance under radiation and long-term high-temperature exposure, where safety and reliability cannot be compromised.

Applications in Petrochemical and Furnace Systems

Beyond power generation, petrochemical plants rely heavily on Incoloy 800HT tubes. These facilities operate furnaces, heat exchangers, and reactors that are exposed to carburizing gases and thermal cycling. Incoloy 800HT provides the resistance needed to maintain structural integrity under these conditions.

Furnace manufacturers also choose this alloy for radiant tubes, muffles, and structural supports. Since furnaces operate continuously at elevated temperatures, material failure can cause significant downtime and costs. Incoloy 800HT minimizes these risks by ensuring long-lasting durability.

Global demand for reliable high-temperature materials is growing rapidly. The energy transition, with a strong focus on expanding nuclear capacity and upgrading fossil-fuel power plants for efficiency, has created an increased need for alloys like Incoloy 800HT.

Another factor driving demand is the global push toward sustainability. Operators are searching for materials that extend service life, reduce replacement cycles, and improve energy efficiency. By resisting creep and oxidation over long periods, Incoloy 800HT contributes to more sustainable operations.

Moreover, stricter safety regulations across industries are increasing reliance on alloys that offer predictable, long-term performance. Incoloy 800HT’s proven track record makes it an ideal choice for compliance with these standards.

Comparison Table: Incoloy 800HT Tube vs Alternatives

| Property | Incoloy 800HT Tube | Incoloy 800 Tube | Stainless Steel 310 Tube | Inconel 600 Tube |

|---|---|---|---|---|

| Base Composition | Nickel-Iron-Chromium + Al, Ti | Nickel-Iron-Chromium | Iron-Chromium-Nickel | Nickel-Chromium |

| Max Service Temp | ~1100°C (2000°F) | ~1100°C (2000°F) | ~1050°C (1920°F) | ~1150°C (2100°F) |

| Creep Resistance | Superior | High | Moderate | Very High |

| Oxidation Resistance | Excellent | Excellent | Good | Excellent |

| Carburization Resistance | Excellent | Excellent | Moderate | Excellent |

| Weldability | Good | Good | Good | Good |

| Long-Term Stability | Excellent (enhanced metallurgical) | Very Good | Moderate | Excellent |

| Typical Applications | Power generation, boilers, turbines | Furnaces, heat exchangers | Kilns, industrial heating | Reactors, aerospace |

Compared to standard Incoloy 800, the 800HT variant is specifically optimized for creep resistance. This makes it more suitable for long-term, high-stress, high-temperature applications.

When compared to stainless steels, Incoloy 800HT clearly outperforms them in terms of creep strength and thermal stability. Stainless steel 310, for instance, can handle moderately high temperatures but is not designed for prolonged exposure at 1000°C and above. Incoloy 800HT, by contrast, is engineered for precisely those conditions.

In comparison with Inconel 600, Incoloy 800HT offers a balance between performance and cost-effectiveness. While Inconel 600 has very high resistance to oxidation, it is generally more expensive, making Incoloy 800HT the practical choice for many industrial projects.

Customization and Supply Capabilities

Every project has unique requirements, and our ability to customize Incoloy 800HT tubes is one of our strongest advantages. We provide a wide range of dimensions, wall thicknesses, and finishes, ensuring that our tubes integrate seamlessly into complex systems.

Our production lines are equipped with advanced testing technologies including non-destructive testing, hydrostatic pressure testing, and chemical composition analysis. These processes guarantee that each tube meets strict mechanical and chemical requirements.

In addition, our supply chain is structured for efficiency. We maintain stocks of standard sizes for quick delivery while also managing custom orders with precision. This combination of readiness and flexibility ensures that our clients receive exactly what they need, when they need it.

Technical Knowledge: A strong foundation in alloy metallurgy and application engineering.

Quality Standards: Comprehensive testing protocols to guarantee consistent performance.

Customization: Ability to produce specialized tubes for demanding projects.

Global Supply: Efficient logistics for clients across multiple regions.

Customer Support: Technical consultation to help clients choose the right solution.

Sustainability Approach: Focus on delivering long-lasting products that support efficient and eco-conscious operations.

These advantages have earned us a reputation as a reliable partner in supplying high-performance alloys worldwide.

Future Outlook

The future of Incoloy 800HT tubes looks bright. With global expansion in nuclear power generation, increasing demand for efficient petrochemical processing, and continuous improvements in furnace and boiler technology, the need for creep-resistant, corrosion-resistant alloys is stronger than ever.

Our company is committed to staying at the forefront of this growth. By investing in advanced manufacturing, expanding research capabilities, and enhancing customer service, we ensure that our Incoloy 800HT tubes continue to meet evolving industry needs.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the primary composition of Incoloy 800HT tube?

Nickel, iron, and chromium with controlled carbon, aluminum, and titanium.What makes Incoloy 800HT different from Incoloy 800?

Improved creep and rupture resistance at high temperatures due to controlled chemistry.What temperature range can Incoloy 800HT tubes handle?

Up to about 1100°C (2000°F).Which industries use Incoloy 800HT most frequently?

Power generation, petrochemical, furnace, and nuclear sectors.Is Incoloy 800HT tube resistant to carburization and oxidation?

Yes, it provides excellent resistance under high-heat atmospheres.Why is Incoloy 800HT preferred in power generation?

Because of its superior creep resistance, thermal stability, and long service life.Can Incoloy 800HT tubes be customized in size and thickness?

Yes, available in various lengths, diameters, and wall thicknesses.How does Incoloy 800HT compare to stainless steel in high-temperature conditions?

It retains strength and resists creep much better than stainless steels.