Incoloy 800HT Tube for Stable Performance in Petrochemical and Furnace Systems

When industries operate in high-temperature and corrosive conditions, material selection becomes one of the most critical decisions. For petrochemical processing plants and furnace systems, the demand for stability, strength, and long-term resistance to degradation is especially high. Incoloy 800H T tubes were developed precisely for these environments, offering superior performance where standard alloys and steels would fail.

As a company specializing in nickel-based alloys, we have extensive experience in producing and supplying Incoloy 800 HT tubes to meet global industry needs. Our commitment to quality, customization, and reliability ensures that our clients receive products capable of delivering stable performance in some of the toughest operating conditions.

Incoloy 800HT is a derivative of the original Incoloy 800, but with significant metallurgical improvements. While both alloys are based on a nickel-iron-chromium foundation, 800HT is engineered with carefully controlled levels of carbon, aluminum, and titanium. These additions enhance the alloy’s ability to resist creep deformation—an essential property for components that are under constant stress at high temperatures.

Creep is one of the primary failure mechanisms in high-temperature service. Materials that slowly deform over time under heat and load can compromise the safety and efficiency of entire systems. By improving creep rupture strength, Incoloy 800HT maintains structural integrity far longer than conventional alloys or stainless steels.

For more details, pls directly contact us.

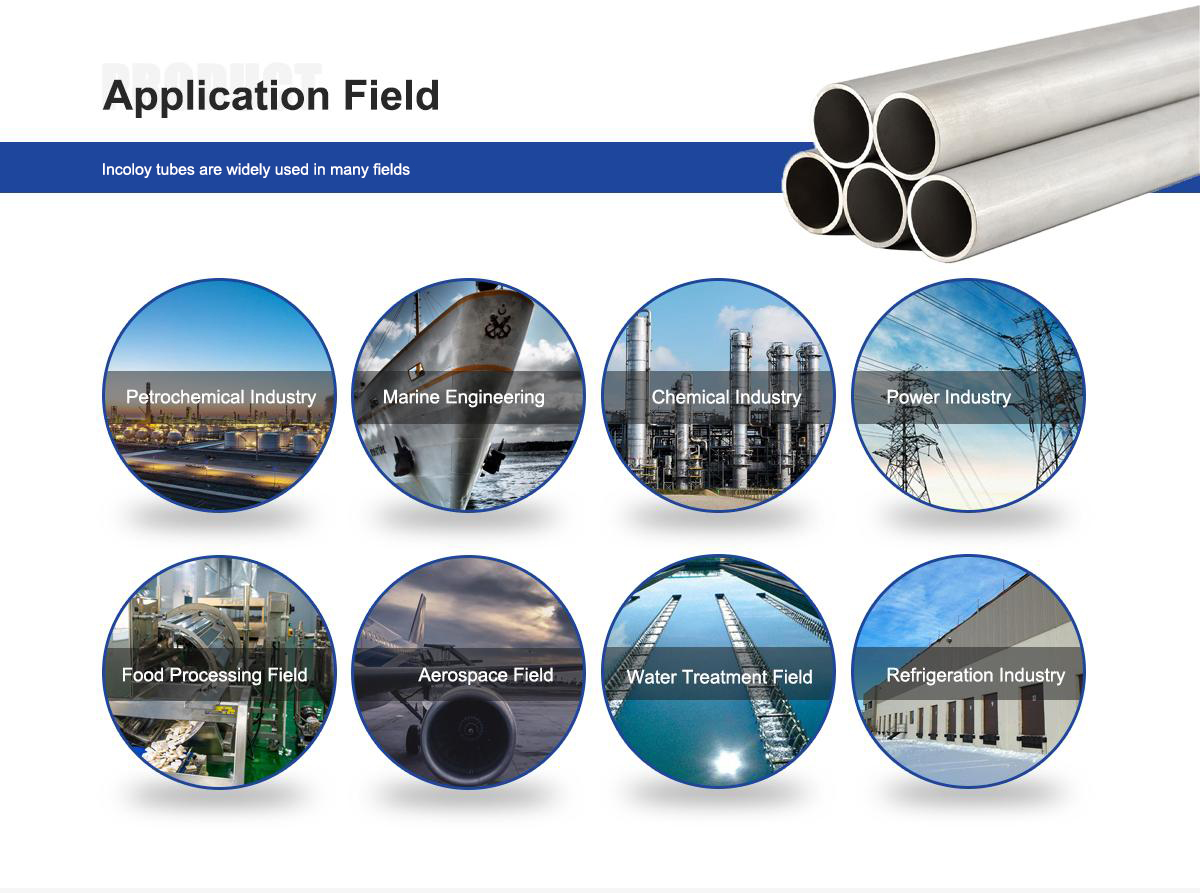

Petrochemical plants operate under some of the harshest industrial conditions. Processes such as hydrocarbon cracking, reforming, and ethylene production expose equipment to carburizing atmospheres, thermal cycling, and corrosive gases. Tubes in heat exchangers, reformer units, and transfer lines are directly exposed to these challenges.

Incoloy 800HT tubes excel in such environments by resisting carburization and oxidation while retaining mechanical strength. This means fewer shutdowns, less maintenance, and greater reliability in continuous operations. For petrochemical operators, this translates directly into higher productivity and lower long-term costs.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Furnace systems are another key area where Incoloy 800HT demonstrates its value. Radiant tubes, muffles, and structural furnace components operate continuously at temperatures near 1100°C. Materials that cannot resist scaling, distortion, or creep will inevitably fail, causing costly downtime.

Incoloy 800HT tubes provide the long-term stability needed in furnace environments. Their oxidation resistance reduces scaling, ensuring tubes maintain efficient heat transfer. Their creep strength allows them to carry loads without warping or collapsing, even after thousands of hours in service. For manufacturers of furnaces and thermal processing equipment, these characteristics are vital.

Expansion of Petrochemical Capacity: As economies grow, the need for refined fuels, plastics, and chemicals increases. This has driven new investments in petrochemical infrastructure, boosting demand for durable tube materials.

Focus on Energy Efficiency: Both petrochemical and furnace operators are under pressure to maximize efficiency. Materials like Incoloy 800HT that extend equipment life and reduce energy losses are increasingly preferred.

Stricter Safety Standards: Regulations worldwide are tightening, requiring equipment to be made of alloys that offer predictable, long-term stability under extreme conditions.

Sustainability Goals: Companies are looking for materials that reduce waste and extend service cycles. Incoloy 800HT contributes to sustainable operations by reducing replacement frequency.

Comparison with Alternatives

While stainless steels like grade 310 are commonly used in high-temperature service, they cannot match the creep resistance or carburization resistance of Incoloy 800HT. Stainless steels also lose mechanical stability more quickly at elevated temperatures, making them less reliable for continuous petrochemical or furnace operations.

Compared to the original Incoloy 800, the 800HT variant provides significantly better creep rupture strength, making it the preferred choice for long-term, high-stress applications.

Against higher-cost alloys such as Inconel 600, Incoloy 800HT offers a balance of affordability and performance. While Inconel 600 is excellent in extreme oxidation environments, many operators find that Incoloy 800HT provides the required stability at a more competitive price.

One of our company’s strengths lies in our ability to deliver customized Incoloy 800HT tubes. Every project comes with unique requirements for size, thickness, and length. We manufacture to exact specifications, ensuring that each tube fits seamlessly into the client’s system.

We also apply advanced non-destructive testing methods—such as ultrasonic and hydrostatic testing—to verify the integrity of every tube. By combining precision manufacturing with rigorous quality control, we ensure that our Incoloy 800HT tubes consistently meet the highest standards.

Our position as a trusted supplier of Incoloy 800HT tubes is built on a combination of expertise, infrastructure, and customer focus:

Deep Metallurgical Knowledge: Our team has years of experience with nickel-based alloys, enabling us to guide clients in material selection and application engineering.

Strict Quality Control: Every batch undergoes chemical analysis, dimensional inspection, and performance testing.

Flexibility in Production: We deliver both standard sizes and custom-engineered tubes for specific projects.

Global Supply Chain: Our logistics network ensures timely delivery to clients worldwide.

Customer Partnership: We work closely with clients to understand their needs and provide tailored solutions.

Sustainability Commitment: By supplying long-lasting materials, we help reduce waste and improve system efficiency.

These advantages allow us to consistently deliver not just tubes, but complete solutions that add value to our clients’ operations.

Comparison Table: Incoloy 800HT Tube vs Alternatives

| Property | Incoloy 800HT Tube | Incoloy 800 Tube | Stainless Steel 310 Tube | Inconel 600 Tube |

|---|---|---|---|---|

| Base Composition | Nickel-Iron-Chromium + Al, Ti | Nickel-Iron-Chromium | Iron-Chromium-Nickel | Nickel-Chromium |

| Max Service Temp | ~1100°C (2000°F) | ~1100°C (2000°F) | ~1050°C (1920°F) | ~1150°C (2100°F) |

| Creep Resistance | Superior (optimized for long-term service) | High | Moderate | Very High |

| Oxidation Resistance | Excellent | Excellent | Good | Excellent |

| Carburization Resistance | Excellent | Excellent | Moderate | Excellent |

| Long-Term Stability | Excellent (controlled carbon + Ti, Al) | Very Good | Moderate | Excellent |

| Weldability | Good | Good | Good | Good |

| Typical Applications | Petrochemical, furnaces, power generation | Heat exchangers, furnaces | Kilns, industrial heating | Aerospace, reactors, furnaces |

Looking ahead, the role of Incoloy 800HT tubes will only become more important. The petrochemical industry continues to expand, and furnace technologies are becoming more advanced and demanding. At the same time, global emphasis on safety, efficiency, and sustainability ensures that high-performance alloys will remain in strong demand.

We are preparing for this future by expanding our production capacity, investing in R&D, and strengthening our customer support capabilities. Our goal is to remain at the forefront of the industry, supplying alloys that enable clients to meet evolving challenges with confidence.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the base composition of Incoloy 800HT tube?

Nickel, iron, and chromium with controlled amounts of carbon, aluminum, and titanium.How does Incoloy 800HT perform in high-temperature petrochemical systems?

It maintains strength, resists creep, and offers excellent carburization resistance.What is the maximum service temperature of Incoloy 800HT tubes?

Around 1100°C (2000°F).Which industries use Incoloy 800HT tubes the most?

Petrochemical plants, furnace systems, power generation, and nuclear facilities.Why is Incoloy 800HT preferred for furnace applications?

Because of its long-term stability, oxidation resistance, and superior creep strength.Can Incoloy 800HT tubes be welded?

Yes, they are weldable with standard procedures.What is the difference between Incoloy 800 and Incoloy 800HT?

800HT has enhanced creep rupture strength and improved high-temperature performance.Can Incoloy 800HT tubes be manufactured to custom specifications?

Yes, sizes, thicknesses, and lengths can be tailored to application needs.