Copper Nickel Busbar for Power Distribution and Renewable Energy Equipment | International Standards

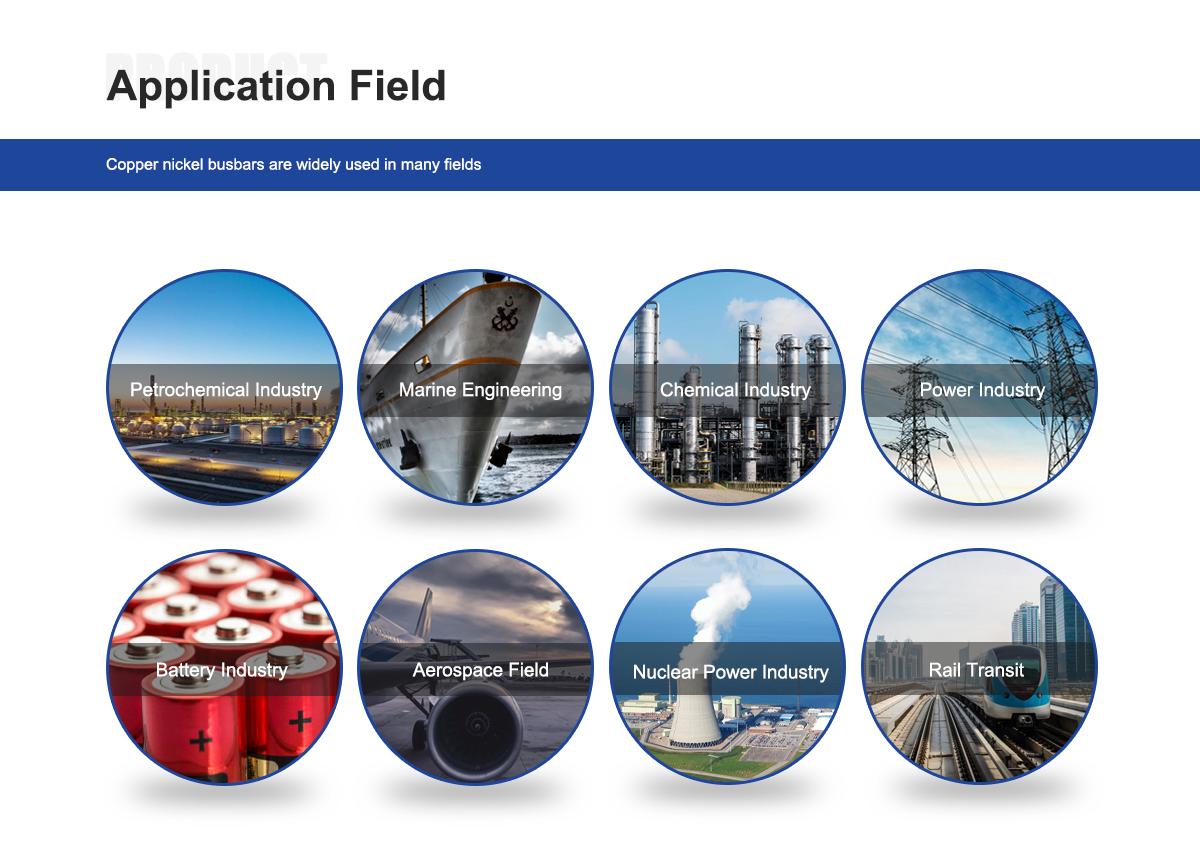

Copper Nickel (CuNi) busbars are increasingly recognized as a premium solution for power distribution and renewable energy equipment. Designed to combine electrical efficiency with superior corrosion resistance, CuNi busbars are engineered for applications that demand long-term reliability, durability, and consistent performance in harsh environments. Their unique combination of copper’s conductivity and nickel’s corrosion resistance makes them particularly suitable for marine, industrial, and renewable energy sectors, where environmental challenges such as humidity, saltwater exposure, and chemical attack are common.

CuNi busbars typically come in 90/10 and 70/30 alloy compositions. The 90/10 CuNi variant provides high copper content, maintaining efficient electrical conductivity while offering excellent corrosion resistance for moderately aggressive environments. The 70/30 CuNi variant, with a higher nickel content, further enhances resistance to corrosion and chemical attack, making it ideal for demanding applications such as offshore platforms, desalination systems, and renewable energy installations exposed to harsh conditions.

Comparison Table

| Property / Alloy Grade | CuNi 90/10 | CuNi 70/30 | Pure Copper (Cu) |

|---|---|---|---|

| Copper Content (%) | 90 | 70 | 100 |

| Nickel Content (%) | 10 | 30 | 0 |

| Max Service Temperature (°C) | 200 | 200 | 150 |

| Corrosion Resistance | Excellent | Superior | Moderate |

| Electrical Conductivity (% IACS) | ~21 | ~12 | 100 |

| Typical Applications | Electrical distribution, marine switchboards, industrial power systems | Offshore platforms, renewable energy equipment, heat exchangers | General electrical systems |

| International Equivalents | ASTM B122, DIN 2.0872, UNS C70600 | ASTM B122, DIN 2.0880, UNS C71500 | ASTM B187 |

For more details, pls directly contact us.

One of the key advantages of CuNi busbars is their mechanical stability under thermal cycling. Electrical distribution systems, especially in renewable energy equipment, often experience fluctuating currents and temperatures. CuNi busbars maintain dimensional stability and resist fatigue, ensuring long-term reliable operation. Their mechanical ductility allows for easier fabrication and installation, reducing project costs and time compared to rigid alternatives.

Compared to traditional pure copper busbars, CuNi alloys significantly reduce the risk of corrosion-related failures. Pure copper, while highly conductive, is vulnerable to oxidation and corrosion in marine or chemical environments, often leading to premature degradation and maintenance requirements. Aluminum busbars, although lightweight, lack the mechanical robustness and corrosion resistance required for long-term applications. CuNi busbars effectively bridge this gap, providing conductivity, mechanical strength, and corrosion resistance in a single material solution.

The demand for CuNi busbars is strongly tied to trends in renewable energy and sustainable infrastructure. As solar farms, wind power installations, and offshore energy platforms expand globally, the need for durable, low-maintenance electrical materials has surged. CuNi busbars are ideal for these applications, offering reliable electrical performance, reduced downtime, and extended service life. Their corrosion resistance in saltwater or high-humidity environments also makes them particularly valuable in coastal and offshore energy projects.

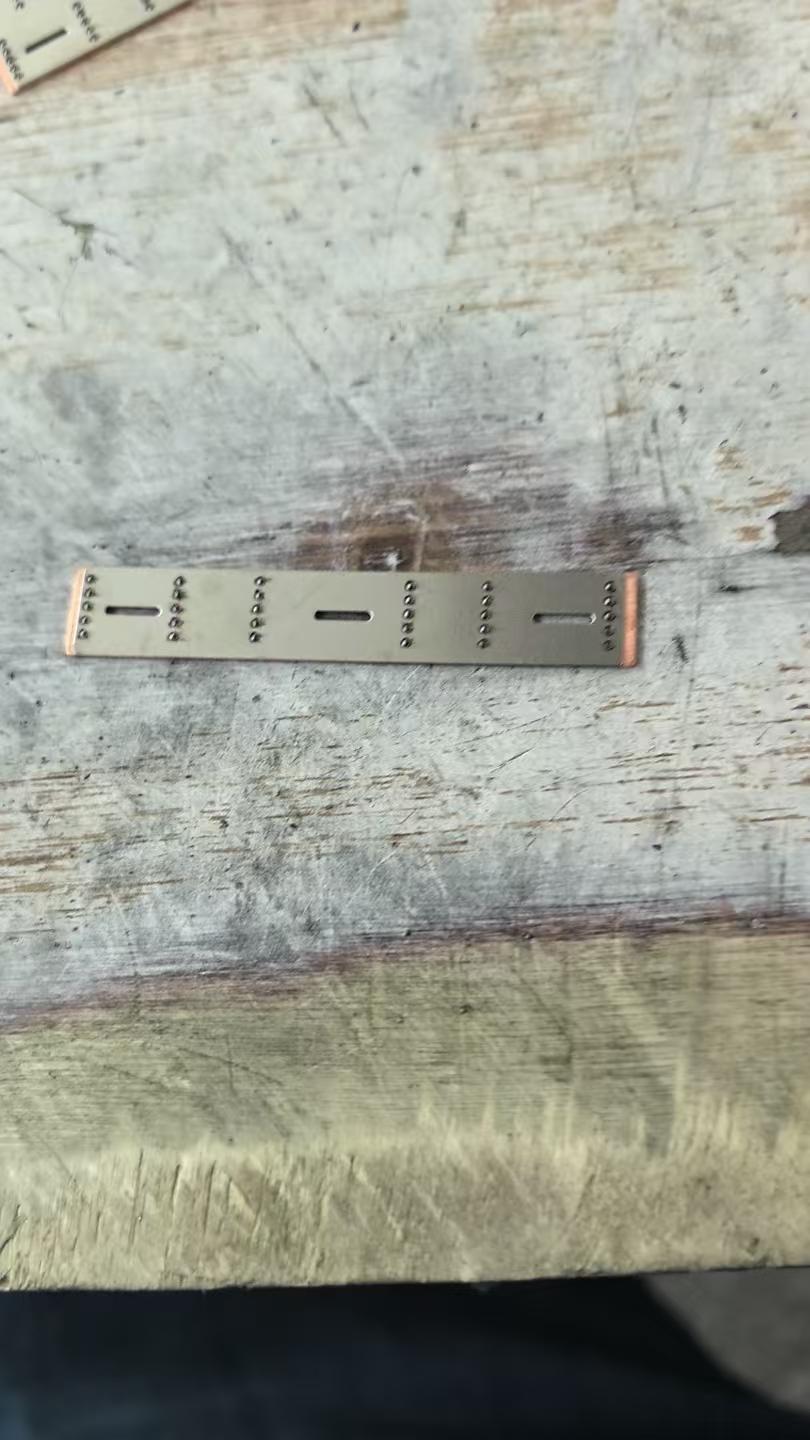

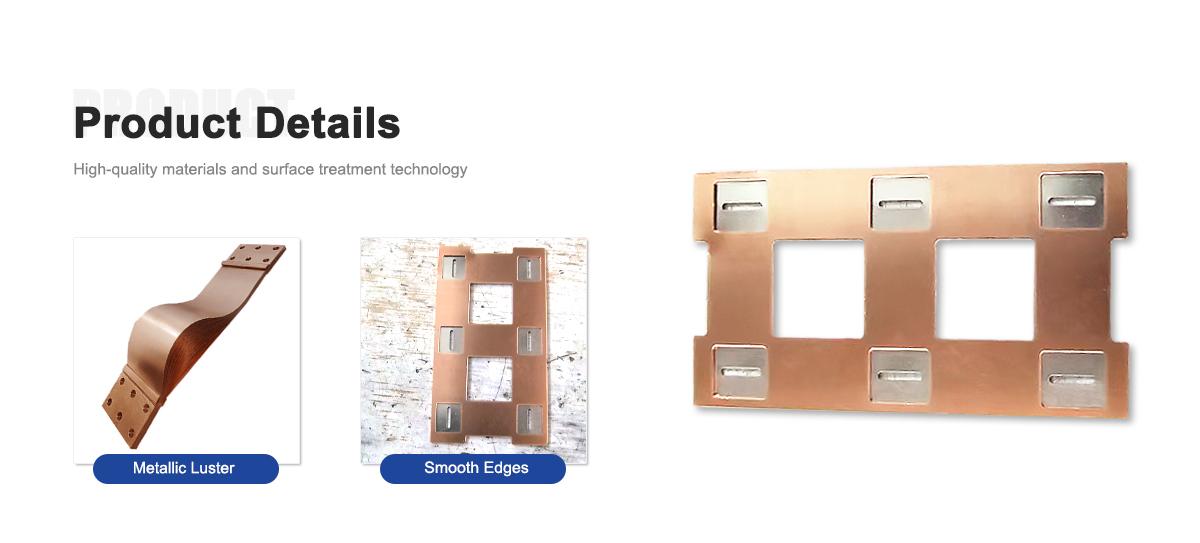

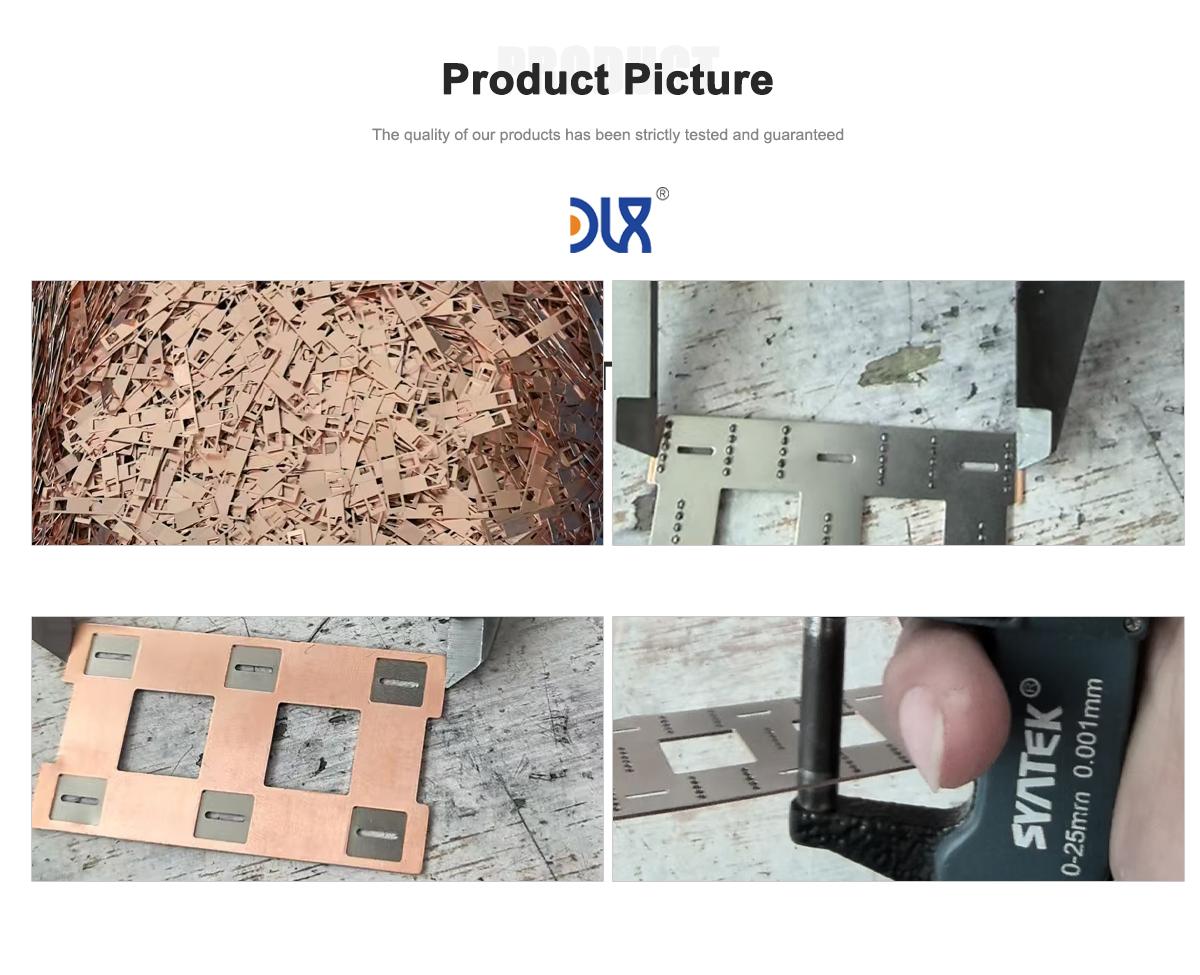

DLX has positioned itself as a global leader in CuNi busbar production by emphasizing quality, precision, and customer-focused solutions. Each busbar is manufactured to strict specifications, ensuring uniform alloy composition, exact dimensions, and smooth surface finishes, all of which are crucial for optimal electrical performance. Quality control measures include conductivity testing, corrosion resistance evaluation, and mechanical integrity assessments to ensure that every busbar meets international standards and client expectations.

International standard compliance is a hallmark of DLX CuNi busbars. For 90/10 CuNi, products conform to ASTM B122, DIN 2.0872, and UNS C70600 specifications. For 70/30 CuNi, equivalents include ASTM B122, DIN 2.0880, and UNS C71500. Compliance with these global standards ensures that DLX busbars integrate seamlessly into international projects, whether for renewable energy installations, industrial electrical systems, or marine equipment.

DLX also offers consultative support to clients, assisting in the selection of appropriate CuNi grades, dimensions, and fabrication processes. This ensures that every busbar meets the specific electrical and environmental requirements of a project. By combining technical expertise with global logistics, DLX guarantees reliable supply, timely delivery, and reduced project risk.

The versatility of CuNi busbars extends across multiple industries. In marine applications, they are used in switchboards, grounding connections, and power distribution networks, performing reliably in saltwater conditions. In industrial power systems, CuNi busbars handle high currents efficiently while minimizing energy losses. Renewable energy applications, including solar and wind installations, benefit from their long-term stability, corrosion resistance, and minimal maintenance requirements.

Market trends indicate a growing preference for materials that offer longevity, sustainability, and energy efficiency. CuNi busbars meet these demands by reducing maintenance cycles, improving reliability, and supporting the operational efficiency of modern energy systems. The shift from traditional copper or aluminum solutions to CuNi alloys reflects the increasing emphasis on performance and lifecycle value in electrical engineering and renewable energy projects.

DLX’s production capabilities include precision cutting, bending, surface finishing, and rigorous testing to ensure each busbar performs consistently under operational conditions. Our customer-focused approach, combined with strict adherence to international standards, provides clients with confidence in material quality, performance, and longevity.

In summary, Copper Nickel busbars are a highly reliable and corrosion-resistant solution for power distribution and renewable energy equipment. The 90/10 and 70/30 alloys provide an ideal balance of electrical conductivity, corrosion resistance, and mechanical strength, suitable for marine, industrial, and renewable energy applications. DLX, with its advanced production techniques, global standard compliance, and consultative support, delivers CuNi busbars that ensure long-term performance, operational reliability, and cost-effective maintenance.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: