High-Performance Copper Nickel (CuNi) Busbar for Marine and Electrical Applications

Copper Nickel (CuNi) busbars are a premium choice for applications demanding a combination of excellent electrical conductivity, superior corrosion resistance, and mechanical durability. With alloy grades such as 90/10 and 70/30 CuNi, these busbars are widely adopted in marine, industrial, and power distribution applications. Their performance under harsh environmental conditions, particularly in seawater and humid atmospheres, makes them indispensable in sectors where reliability and longevity are critical.

The defining feature of CuNi busbars is their unique balance between copper’s high conductivity and nickel’s superior resistance to corrosion. This combination allows the busbar to carry significant electrical current while withstanding chemical attack, biofouling, and general oxidation. The CuNi 90/10 variant maintains high copper content for better conductivity while offering enhanced resistance to marine corrosion, making it the preferred choice for shipbuilding and offshore electrical systems. CuNi 70/30, with higher nickel content, provides even stronger corrosion resistance, suitable for highly aggressive environments such as saltwater heat exchangers or submerged electrical components.

| Property / Alloy Grade | CuNi 90/10 | CuNi 70/30 | Pure Copper (Cu) |

|---|---|---|---|

| Copper Content (%) | 90 | 70 | 100 |

| Nickel Content (%) | 10 | 30 | 0 |

| Max Service Temp (°C) | 200 | 200 | 150 |

| Corrosion Resistance | Excellent | Very Good | Good |

| Conductivity (% IACS) | ~21 | ~12 | 100 |

| Typical Applications | Marine, shipbuilding, power distribution, heat exchangers | Marine, saltwater equipment, electrical busbars | General electrical applications |

| International Equivalents | ASTM B122, DIN 2.0872, UNS C70600 | ASTM B122, DIN 2.0880, UNS C71500 | ASTM B187 |

For more details, pls directly contact us.

From a materials perspective, CuNi busbars also offer excellent mechanical strength. They maintain dimensional stability under thermal cycling, which is critical in electrical distribution systems that experience fluctuating loads. Their ductility allows for easy fabrication, bending, and joining without compromising performance. Compared to pure copper busbars, CuNi options provide a longer service life in corrosive environments, reducing maintenance costs and operational downtime.

The versatility of CuNi busbars extends across various industries. In marine applications, they are used extensively for shipboard power systems, grounding connections, and switchboards. The combination of corrosion resistance and conductivity ensures reliable electrical performance even in salt-laden atmospheres. In power distribution and renewable energy systems, CuNi busbars handle high-current connections in a compact footprint, ensuring stable voltage transmission and minimizing energy losses. Furthermore, industrial equipment such as desalination plants, chemical processing units, and heat exchangers benefit from CuNi busbars due to their resistance to corrosion and biofouling.

Global trends indicate an increasing demand for CuNi busbars in both traditional marine sectors and emerging renewable energy applications. Offshore wind farms, solar power plants, and electric shipbuilding are driving the adoption of high-performance, corrosion-resistant materials. The shift toward sustainable energy and durable infrastructure necessitates materials that can withstand harsh conditions without frequent replacement. CuNi busbars perfectly align with these market needs, offering a cost-effective solution for long-term electrical performance.

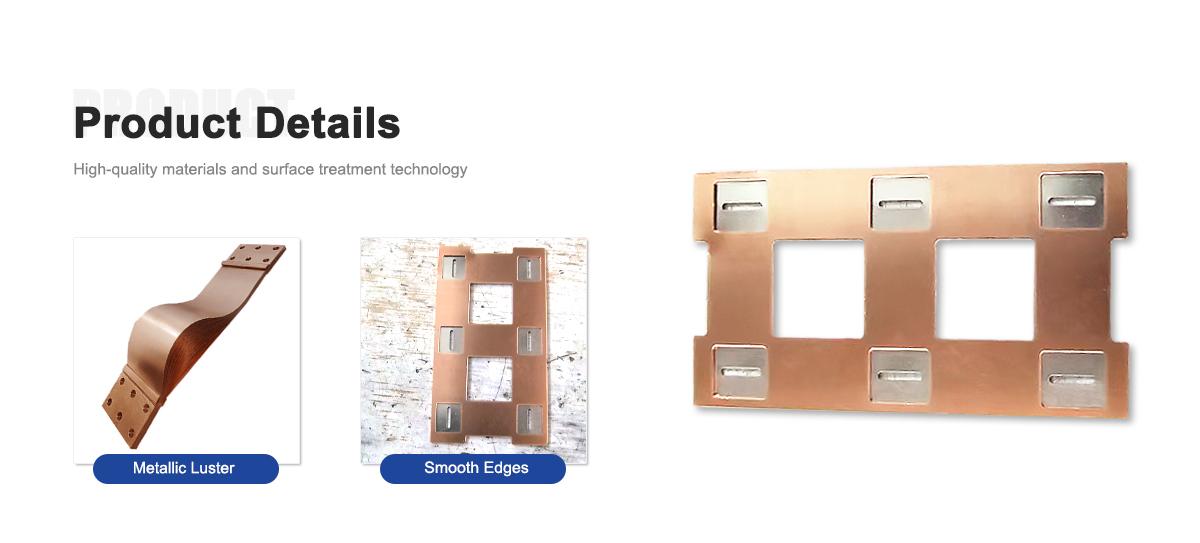

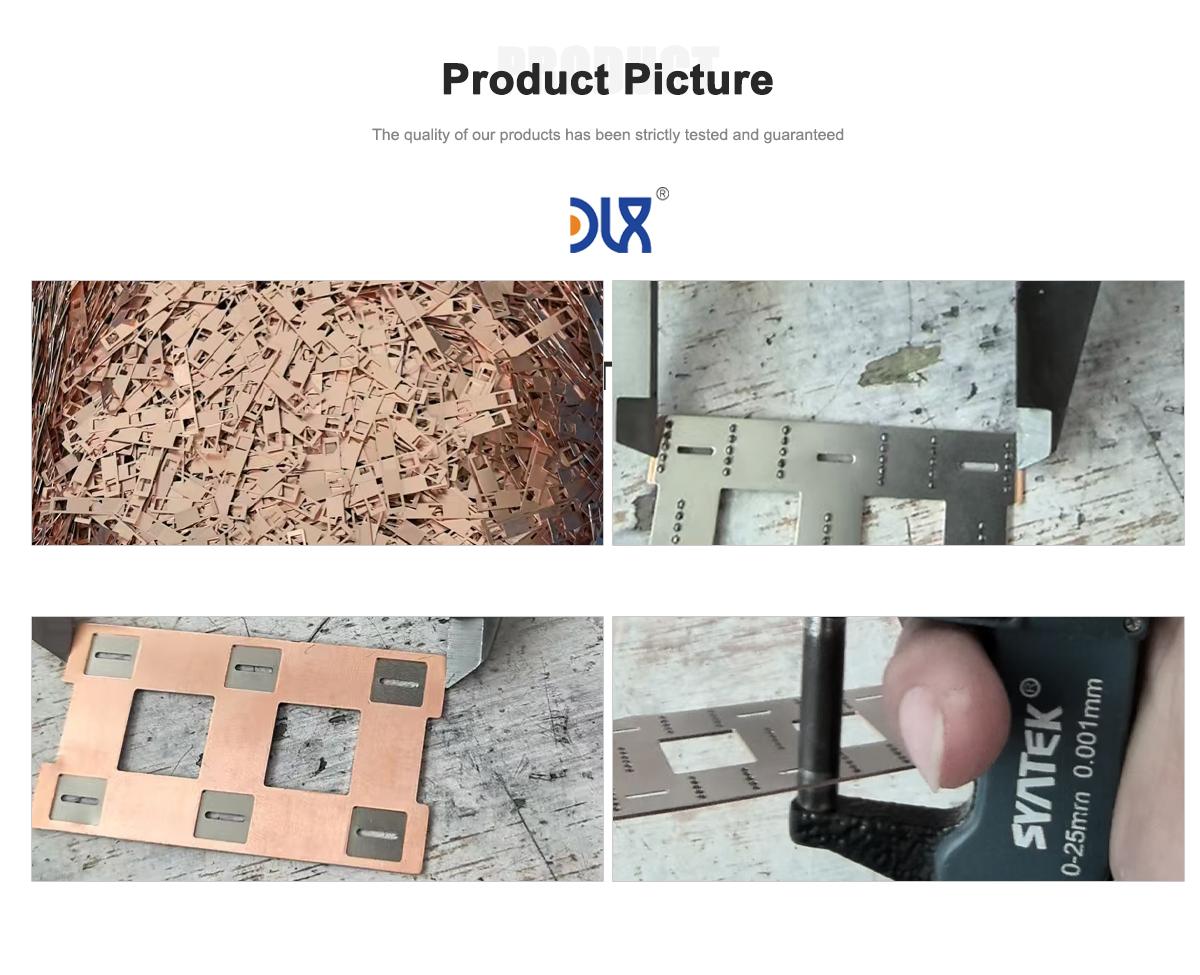

DLX stands out as a leading supplier of Copper Nickel busbars by combining high-quality alloy production, precise fabrication, and robust technical support. Our production process ensures uniform alloy composition, exact dimensions, and smooth surface finishes, which are essential for electrical efficiency and ease of installation. Each busbar is tested to meet stringent conductivity, corrosion resistance, and mechanical performance standards.

One of the main advantages of sourcing from DLX is our ability to provide international-grade CuNi busbars compatible with ASTM, DIN, UNS, and other recognized standards. For example, ASTM B122 and DIN 2.0872/C70600 represent widely used CuNi 90/10 specifications, while CuNi 70/30 equivalents include ASTM B122, DIN 2.0880, and UNS C71500. This ensures that our products integrate seamlessly into global systems, whether for new installations or retrofits.

Compared to other suppliers, DLX combines engineering expertise with customer-oriented service. We advise clients on selecting the appropriate CuNi alloy, dimensions, and fabrication options based on application, environment, and electrical requirements. This consultative approach minimizes errors, optimizes performance, and extends the service life of the busbars. Moreover, our global logistics network ensures timely delivery, supporting projects across Europe, North America, Asia, and beyond.

The performance advantages of CuNi busbars are especially evident when compared to traditional copper or aluminum busbars in marine and industrial settings. While copper provides excellent conductivity, it is prone to rapid corrosion in seawater. Aluminum is lightweight and cost-effective but lacks the mechanical robustness and corrosion resistance needed for long-term marine applications. CuNi busbars, by contrast, offer a balanced solution: they combine electrical efficiency with the strength and durability necessary for demanding environments.

With the rise of electrification in marine vessels, renewable energy platforms, and industrial equipment, CuNi busbars are positioned as a critical material for reliable electrical distribution. They ensure that energy is transmitted efficiently while minimizing maintenance and replacement costs. This trend is likely to accelerate as industries increasingly prioritize sustainability, energy efficiency, and operational reliability.

DLX continues to innovate in CuNi busbar production by leveraging modern metallurgical techniques and fabrication methods. From precision cutting and bending to surface finishing and testing, every step is controlled to meet strict quality standards. This commitment ensures that clients receive busbars that not only meet technical specifications but also deliver consistent performance throughout their operational life.

In conclusion, Copper Nickel busbars represent the ideal choice for electrical applications that demand high performance in challenging environments. With exceptional corrosion resistance, stable conductivity, and mechanical strength, CuNi busbars serve a wide range of applications from marine vessels to industrial power distribution systems. DLX, with its advanced production capabilities, global standards compliance, and customer-focused approach, delivers CuNi busbars that provide reliable, long-term performance, helping industries achieve operational efficiency and cost savings.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: