High-Conductivity UNS C71500 70/30 Copper Nickel Busbar for Industrial Power Systems

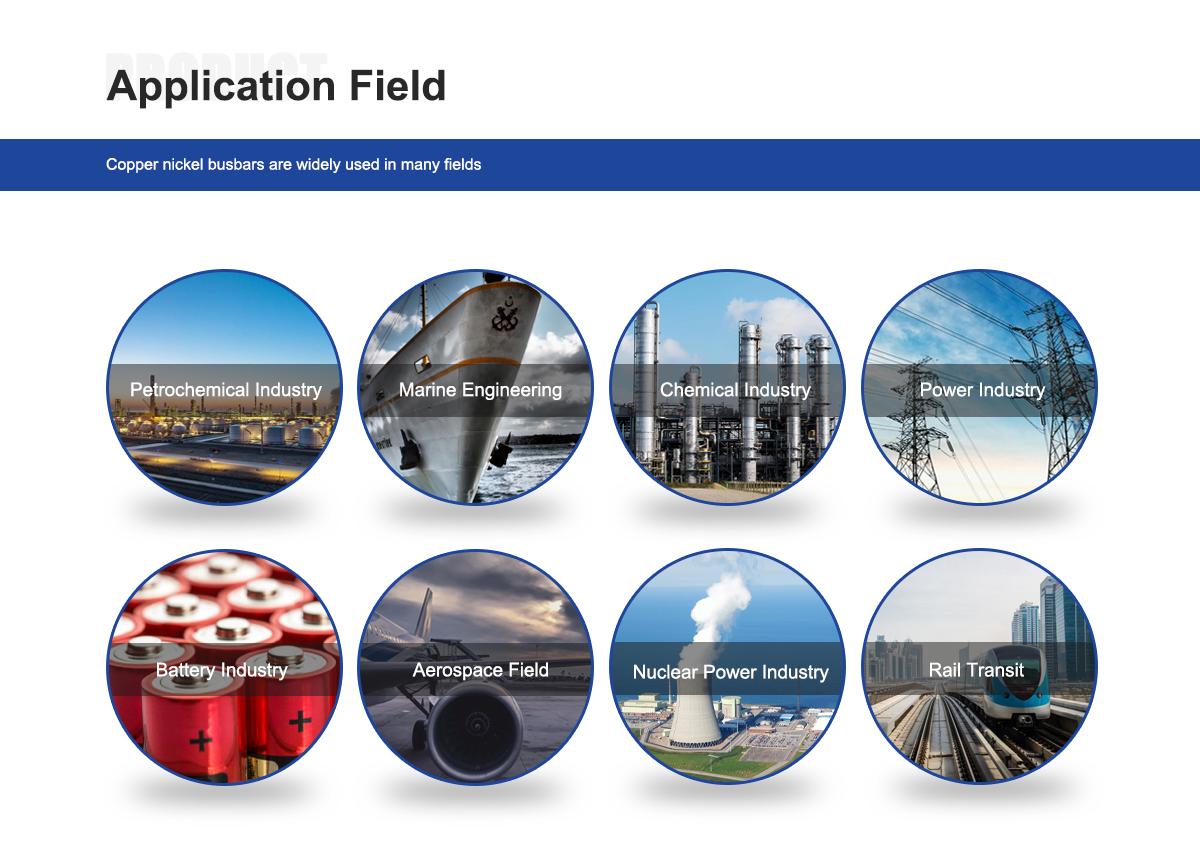

Copper Nickel (CuNi) busbars are a critical material in modern industrial power systems, offering a unique combination of electrical conductivity, mechanical strength, and corrosion resistance. Among these, the UNS C71500 70/30 CuNi busbar stands out for its enhanced corrosion resistance and mechanical durability, making it ideal for demanding industrial applications. DLX produces premium 70/30 CuNi busbars that meet international standards, ensuring reliable performance in complex and harsh industrial environments.

The 70/30 CuNi alloy contains 70% copper and 30% nickel, providing superior resistance to corrosion, particularly in aggressive industrial atmospheres, chemical exposure, or offshore environments. While the 90/10 CuNi alloy offers higher electrical conductivity, 70/30 CuNi excels in maintaining mechanical integrity and resisting chemical attack in extreme conditions. This makes it the preferred choice for industrial power systems that require long-term reliability under high load and environmental stress.

| Property / Alloy Grade | CuNi 70/30 (C71500) | CuNi 90/10 (C70600) | Pure Copper (Cu) |

|---|---|---|---|

| Copper Content (%) | 70 | 90 | 100 |

| Nickel Content (%) | 30 | 10 | 0 |

| Max Service Temperature (°C) | 200 | 200 | 150 |

| Corrosion Resistance | Superior | Excellent | Moderate |

| Electrical Conductivity (% IACS) | ~12 | ~21 | 100 |

| Typical Applications | Industrial power systems, offshore platforms, heat exchangers | Marine switchboards, industrial electrical distribution | General electrical distribution |

| International Equivalents | ASTM B122, DIN 2.0880, UNS C71500 | ASTM B122, DIN 2.0872, UNS C70600 | ASTM B187 |

For more details, pls directly contact us.

UNS C71500 70/30 CuNi busbars are widely used in industrial power systems, including switchboards, busway assemblies, high-current distribution panels, and offshore electrical platforms. Their corrosion resistance ensures minimal maintenance and extended operational life, while their mechanical stability allows for precision bending, cutting, and installation without compromising performance.

One of the key advantages of 70/30 CuNi busbars is their performance in high-current industrial applications. Electrical distribution systems often experience fluctuating loads, which can cause thermal cycling and mechanical stress. 70/30 CuNi maintains dimensional stability and resists fatigue, ensuring consistent electrical performance over time. Compared to pure copper or aluminum busbars, CuNi provides a balance of conductivity, mechanical strength, and corrosion resistance, making it highly reliable for industrial operations.

Industrial environments, particularly those with exposure to chemicals, moisture, or offshore conditions, demand materials that maintain integrity under challenging conditions. Pure copper, although highly conductive, corrodes rapidly under such conditions, leading to increased maintenance and reduced service life. Aluminum, while lightweight, cannot withstand aggressive environments and high current loads without deformation. UNS C71500 CuNi busbars address these challenges by offering a durable, corrosion-resistant, and mechanically robust solution for industrial power systems.

Global trends in renewable energy, offshore power generation, and industrial automation have increased the demand for reliable CuNi busbars. Industries are moving toward materials that provide longevity, operational efficiency, and reduced maintenance. UNS C71500 70/30 CuNi busbars meet these requirements, providing superior performance in high-demand electrical applications and ensuring long-term reliability.

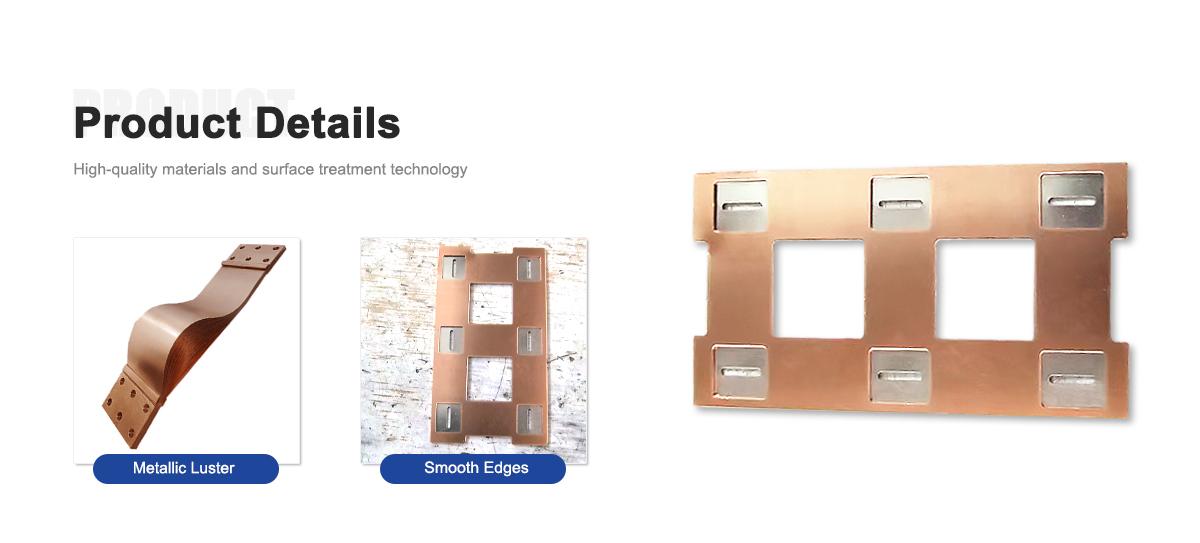

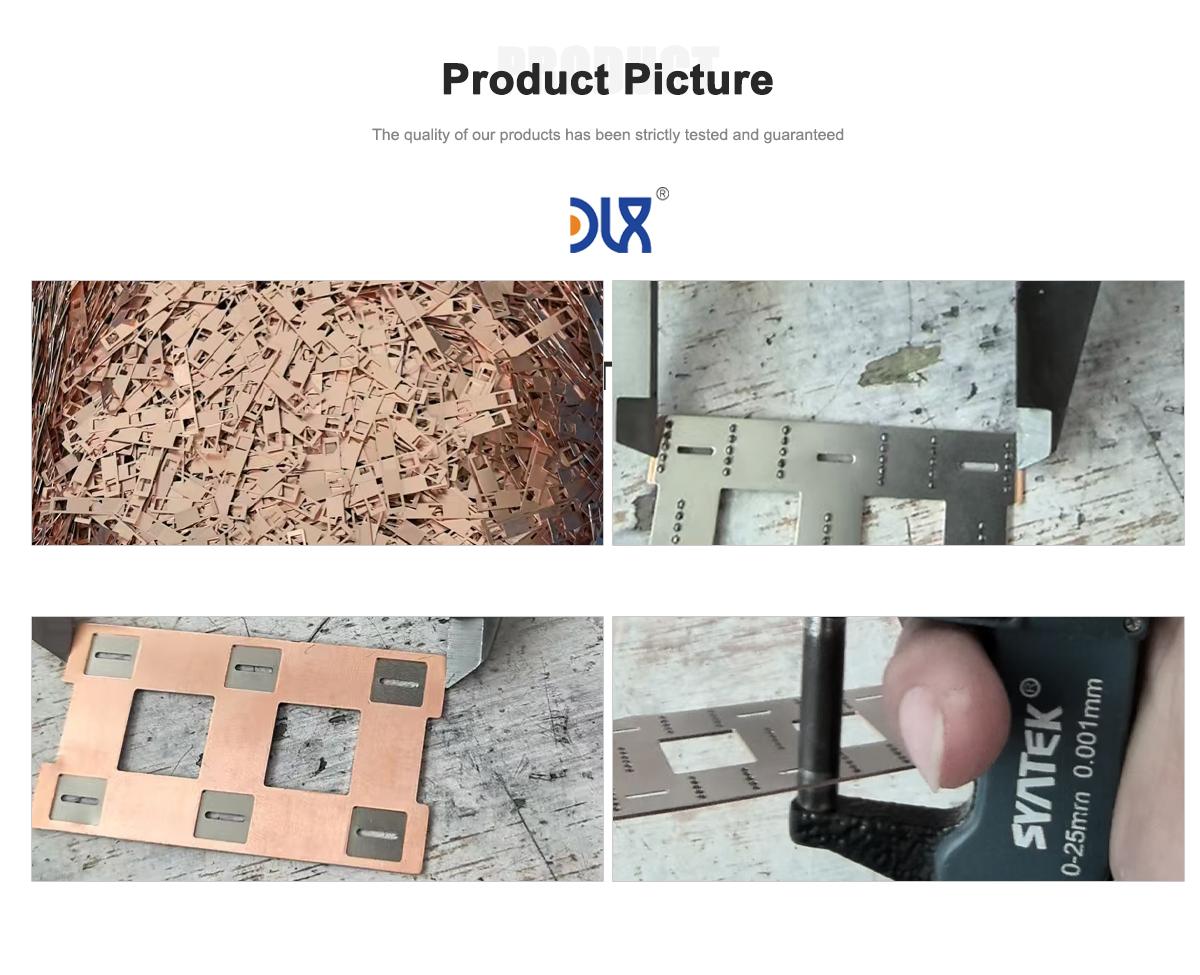

DLX distinguishes itself by producing CuNi busbars to the highest standards of quality and precision. Each busbar is subjected to strict quality control processes, including alloy composition verification, dimensional accuracy, surface finish assessment, and mechanical testing. Electrical conductivity, corrosion resistance, and mechanical integrity are thoroughly evaluated to guarantee reliable performance in industrial power systems.

International standard compliance is another key strength of DLX CuNi busbars. UNS C71500 70/30 products comply with ASTM B122, DIN 2.0880, and UNS C71500 specifications. This ensures that DLX busbars meet global project requirements and integrate seamlessly into industrial power systems worldwide, providing engineers and project managers with confidence in material reliability.

DLX also provides expert consultative support, assisting clients in selecting the appropriate busbar alloy, size, and fabrication process to match specific project requirements. This reduces installation risks, ensures optimal performance, and helps clients achieve long-term operational efficiency. Coupled with a robust global supply chain, DLX delivers CuNi busbars promptly to industrial projects across multiple regions, supporting both new installations and retrofits.

In industrial applications, 70/30 CuNi busbars excel in high-current distribution panels, offshore platforms, renewable energy substations, and industrial switchboards. Their corrosion resistance, combined with mechanical stability, ensures reliable performance over years of continuous operation. Maintenance requirements are minimal, reducing operational downtime and associated costs.

The market trend is shifting toward materials that provide both long-term durability and sustainability. UNS C71500 70/30 CuNi busbars meet these demands by providing extended service life, reduced maintenance, and reliable electrical performance. As industries increasingly prioritize energy efficiency and sustainability, CuNi busbars are becoming the material of choice for high-performance industrial power systems.

DLX continuously improves production processes to maintain premium quality. Precision cutting, bending, surface finishing, and comprehensive testing ensure that every busbar meets stringent industrial requirements. This meticulous attention to detail guarantees that clients receive CuNi busbars capable of performing reliably under demanding industrial conditions for decades.

In conclusion, UNS C71500 70/30 Copper Nickel busbars provide an optimal solution for high-current industrial power systems. Their superior corrosion resistance, mechanical strength, and reliable conductivity make them ideal for demanding applications, including offshore platforms, industrial distribution systems, and renewable energy substations. DLX, through advanced manufacturing, international standard compliance, and customer-focused support, delivers premium CuNi busbars that meet modern industrial power system demands while minimizing maintenance and ensuring long-term operational reliability.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: