Premium C70600 Copper Nickel Busbar - Corrosion-Resistant 90/10 CuNi for Marine Applications

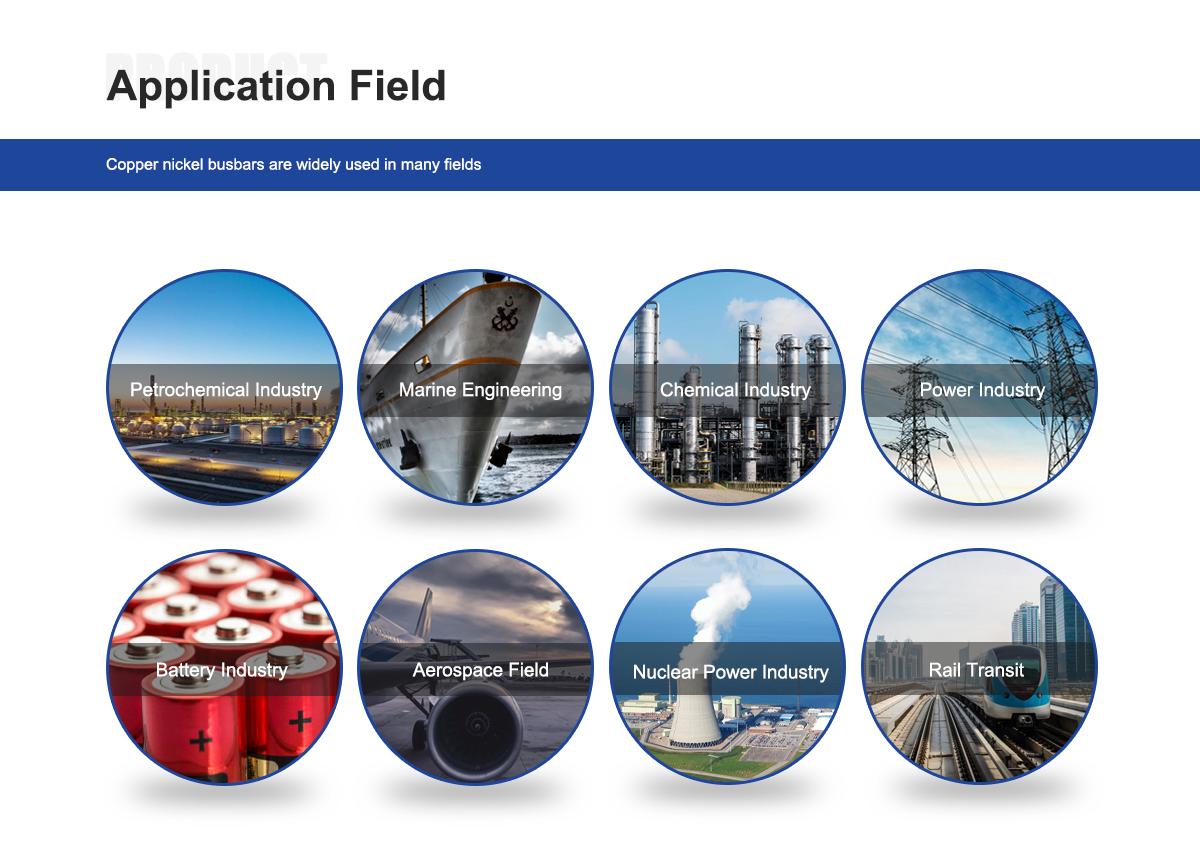

Copper Nickel (CuNi) busbars have become an essential component in modern marine electrical systems, combining electrical efficiency with exceptional corrosion resistance. The C70600 90/10 CuNi busbar is particularly engineered for marine applications, delivering high performance in environments exposed to saltwater, humidity, and fluctuating electrical loads. DLX specializes in manufacturing these premium CuNi busbars, ensuring adherence to international standards and providing long-term reliability for shipbuilding and offshore electrical distribution systems.

The C70600 90/10 CuNi busbar consists of 90% copper and 10% nickel. This composition ensures that the busbar maintains excellent electrical conductivity while significantly improving corrosion resistance compared to pure copper. In marine environments, where saltwater and moisture can quickly degrade standard copper or aluminum busbars, C70600 CuNi provides a robust solution that minimizes maintenance and extends service life.

| Property / Alloy Grade | C70600 CuNi 90/10 | Pure Copper (Cu) | Aluminum (Al) |

|---|---|---|---|

| Copper Content (%) | 90 | 100 | 100 |

| Nickel Content (%) | 10 | 0 | 0 |

| Max Service Temperature (°C) | 200 | 150 | 100 |

| Corrosion Resistance | Excellent | Moderate | Low |

| Electrical Conductivity (% IACS) | ~21 | 100 | ~61 |

| Typical Applications | Marine switchboards, offshore platforms, ship electrical distribution | General electrical systems | Lightweight electrical applications |

| International Equivalents | ASTM B122, DIN 2.0872, UNS C70600 | ASTM B187 | ASTM B298 |

For more details, pls directly contact us.

Marine electrical systems require materials that can endure continuous exposure to harsh environments. C70600 busbars provide mechanical stability under thermal cycling, which is critical in applications such as shipboard switchboards, grounding systems, and offshore platform power distribution. Their superior ductility allows for precise fabrication, bending, and installation without compromising electrical performance.

Compared with traditional copper or aluminum busbars, CuNi offers a unique combination of durability, corrosion resistance, and electrical conductivity. Pure copper, while highly conductive, suffers from rapid oxidation in saltwater conditions. Aluminum, although lightweight, lacks the mechanical strength and corrosion resistance needed for long-term marine applications. C70600 90/10 CuNi busbars effectively balance these requirements, making them the ideal choice for marine electrical infrastructure.

Global demand for corrosion-resistant CuNi busbars is growing in tandem with the expansion of offshore energy, shipbuilding, and marine transport sectors. Offshore platforms, desalination plants, and naval vessels require busbars that can deliver reliable performance under continuous electrical load while resisting corrosive elements. The adoption of C70600 CuNi busbars reduces downtime, minimizes maintenance, and ensures operational safety for critical electrical systems.

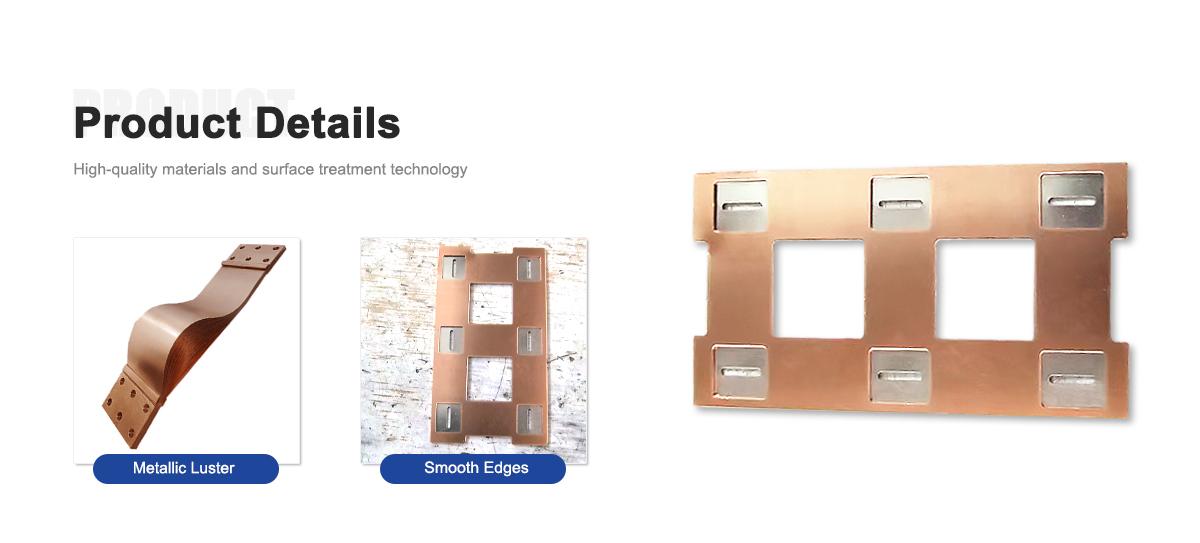

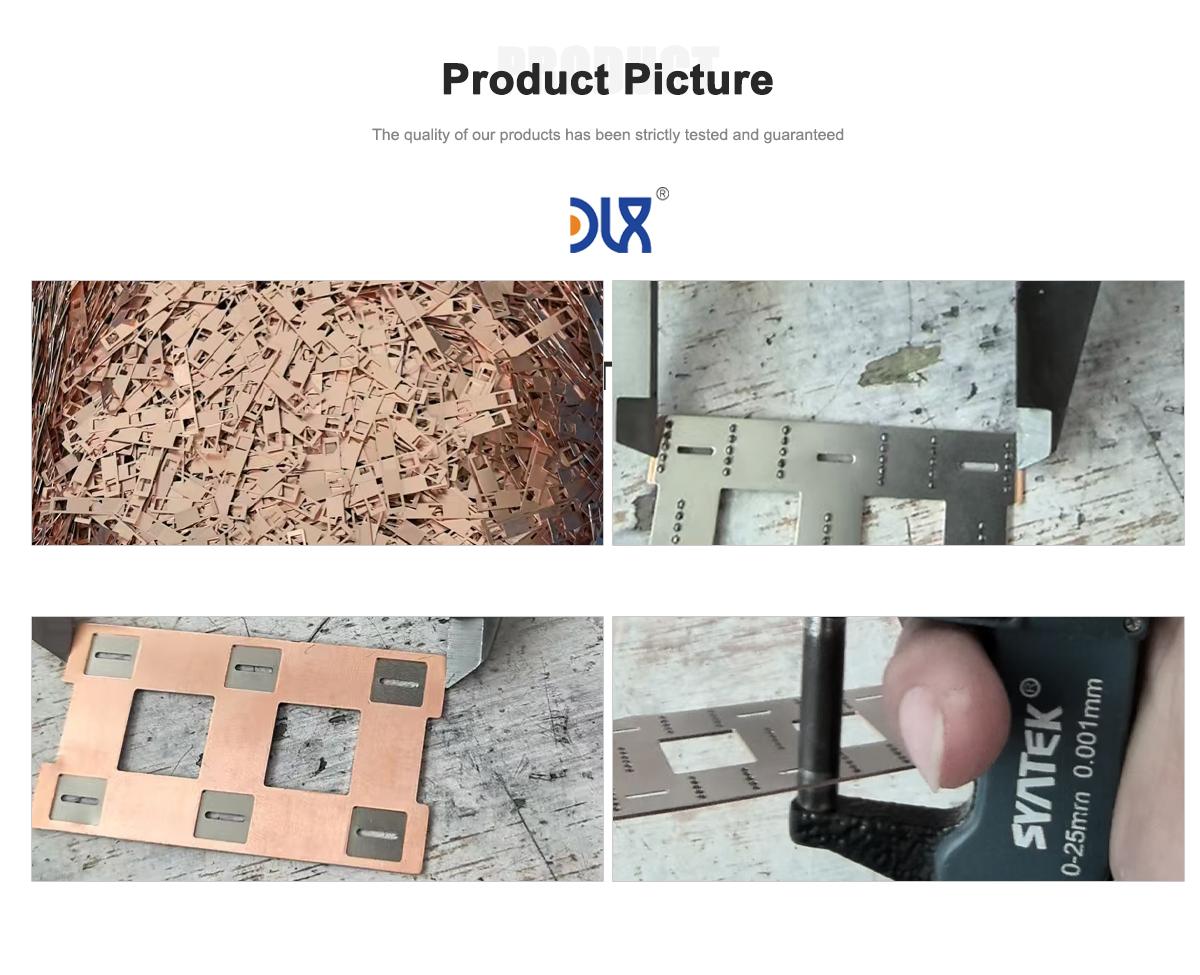

DLX has positioned itself as a leading provider of C70600 90/10 CuNi busbars by combining advanced manufacturing techniques with rigorous quality assurance. Each busbar undergoes precise alloy composition checks, dimensional verification, and surface finish assessments. Conductivity, mechanical integrity, and corrosion resistance are tested to guarantee performance under demanding marine conditions.

International standard compliance is a key advantage of DLX CuNi busbars. C70600 90/10 busbars conform to ASTM B122, DIN 2.0872, and UNS C70600 standards. This ensures that our products meet global project requirements and integrate seamlessly into marine electrical systems worldwide. Engineers and procurement teams can specify DLX busbars with confidence, knowing that they adhere to internationally recognized specifications.

DLX also provides consultative support, assisting clients in selecting the optimal busbar size, grade, and fabrication process based on project specifications. This tailored approach reduces installation risks and ensures long-term reliability. Coupled with a global logistics network, DLX delivers high-quality CuNi busbars promptly, supporting shipyards, offshore facilities, and marine electrical projects across continents.

In marine applications, CuNi busbars excel in switchboards, grounding connections, and power distribution networks. Their corrosion resistance protects against saltwater, biofouling, and oxidation, maintaining both structural integrity and electrical performance. Industrial and renewable energy sectors also benefit from these busbars, where high-current loads and corrosive conditions are prevalent.

Market trends emphasize the need for sustainable, long-lasting materials that lower operational costs and maintenance frequency. C70600 CuNi busbars meet these criteria by providing long-term electrical and mechanical stability, minimizing energy loss, and extending the service life of marine electrical systems. Industries increasingly prefer CuNi busbars over copper or aluminum alternatives for both performance and lifecycle cost efficiency.

DLX continuously invests in production innovations, including precision cutting, bending, surface finishing, and comprehensive testing. Every busbar is manufactured to deliver consistent electrical conductivity, mechanical stability, and corrosion resistance. This meticulous attention to quality ensures that clients receive CuNi busbars capable of performing reliably over years of continuous marine and industrial operation.

In summary, the C70600 90/10 CuNi busbar is a premium solution for marine and industrial electrical applications. Combining excellent conductivity, superior corrosion resistance, and mechanical strength, these busbars offer long-term reliability and reduced maintenance for shipbuilding, offshore platforms, and other critical electrical systems. DLX, through advanced production processes, adherence to international standards, and customer-focused service, provides high-quality CuNi busbars that meet the demands of modern marine and industrial infrastructure.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: