Constantan 6J11 Alloy Strip for Precision Instruments and Resistor Manufacturing

The Constantan 6J11 Alloy Strip is a trusted resistance alloy designed for precision instruments and resistor manufacturing. Known for its balance of copper and nickel, with a composition of approximately 60% copper and 40% nickel, it delivers stable resistivity and reliable performance across a broad range of temperatures. This makes it a highly valued material in electronics, sensors, and industrial systems requiring long-term accuracy.

At DLX, we manufacture Constantan 6J11 Alloy Strip with precision, ensuring consistency and tight dimensional tolerances. Our focus is not only on supplying materials but also on creating solutions that support the most demanding applications in precision instruments and resistive components.

For more details, pls directly contact us.

The global demand for resistance alloys like Constantan 6J11 is expanding due to rapid advancements in electronics, aerospace, renewable energy, and automation technologies. Each sector requires materials that can withstand environmental changes while maintaining stable resistivity.

Electronics and Instrumentation: Miniaturized electronic devices require materials with predictable resistance values. Constantan 6J11 fits perfectly, ensuring reliable output in compact designs.

Aerospace and Automotive: Aircraft and vehicles increasingly depend on advanced sensors, strain gauges, and resistors, all of which rely on alloys like 6J11 for stable operation.

Renewable Energy Systems: Solar, wind, and hydro power plants use precise monitoring systems, where constant resistance ensures accurate data collection.

Industrial Automation: As factories integrate more control and monitoring systems, resistance alloys like Constantan 6J11 play a key role in delivering measurement accuracy.

These factors make Constantan 6J11 an indispensable material in today’s fast-developing industries.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 | |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 | |

0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 | |

0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 | |

0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 | |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 | |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 | |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

The Constantan 6J11 Strip serves a variety of industries thanks to its unique balance of stability, corrosion resistance, and workability.

Precision Resistors: Delivers consistent resistance values required in high-performance circuits.

Strain Gauges: Ensures accurate stress measurement in automotive, civil engineering, and aerospace applications.

Industrial Sensors: Provides stable performance under different load and environmental conditions.

Thermocouples: Functions effectively as a compensating material in thermoelectric devices.

Instrumentation Components: Supports advanced measuring equipment used across scientific and industrial research.

Automotive Electronics: Applied in diagnostic and monitoring systems for enhanced accuracy.

DLX Company Advantages

DLX offers a significant edge in the production and supply of Constantan 6J11 Alloy Strip. Our approach focuses on precision, customization, and long-term client satisfaction.

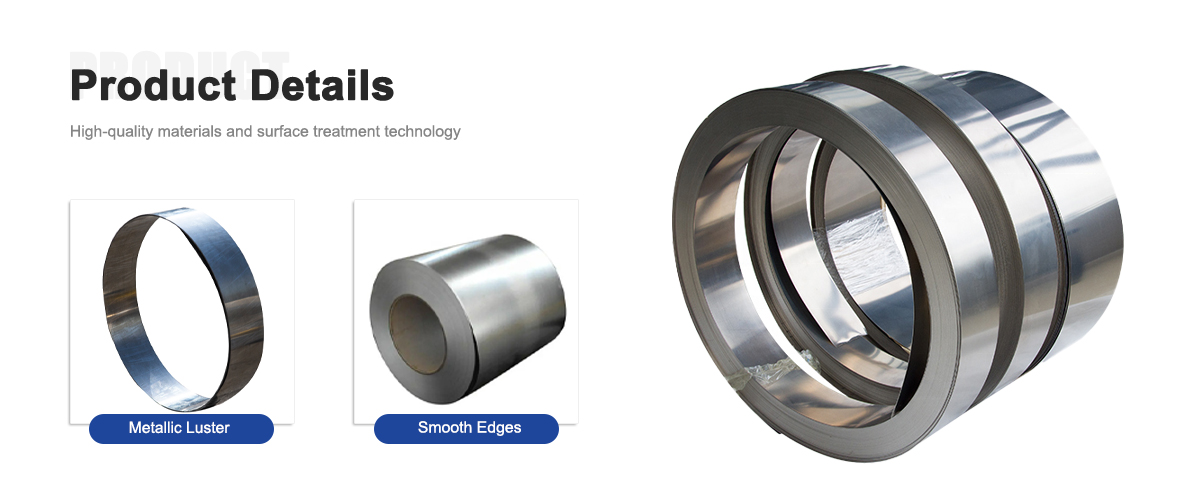

Precision Quality: DLX controls every production stage, ensuring uniform resistivity and exact strip dimensions.

Customized Manufacturing: We adapt our production lines to meet unique client specifications for specialized projects.

Consistent Reliability: Our rigorous quality assurance processes ensure every strip meets international standards.

Scalable Supply: From small experimental orders to large industrial quantities, we can deliver without compromising on quality.

Expert Support: Our technical team provides in-depth consultation to help clients optimize the use of 6J11 strips in their applications.

This customer-centered philosophy sets DLX apart as more than a supplier—we are a reliable partner in innovation.

Comparison Table: Constantan 6J11 vs Other Resistance Alloys

| Property | Constantan 6J11 Strip | Constantan 6J40 Strip | Manganese Bronze 6J12 Strip | Manganese Bronze 6J13 Strip | Manganese Bronze 6J8 Strip |

|---|---|---|---|---|---|

| Composition | Cu 60%, Ni 40% | Cu 55%, Ni 45% | Cu-Zn-Mn | Cu-Zn-Mn | Cu-Zn-Mn |

| Resistivity (Ω·mm²/m) | ~0.49 | ~0.48 | Lower | Lower | Lower |

| Temperature Stability | Very Good | Excellent | Moderate | Moderate | Moderate |

| Corrosion Resistance | High | High | Medium | Medium | Medium |

| Typical Applications | Resistors, instruments, gauges | Sensors, resistors, thermocouples | Marine hardware, parts | Connectors, machinery | Structural parts |

Several trends highlight why Constantan 6J11 is becoming increasingly important:

Electronics Miniaturization: As devices shrink, resistive components must deliver higher precision in smaller sizes.

Growth of Smart Manufacturing: Precision instruments in automated environments require alloys that perform consistently over time.

Green Energy Expansion: Renewable energy systems demand long-lasting resistance materials to maintain accurate data collection.

Infrastructure Development: Expanding global infrastructure needs advanced sensors and control systems built from reliable materials like Constantan 6J11.

These trends are shaping the global market, and DLX continues to evolve our production capabilities to meet emerging requirements.

DLX vs. Generic Suppliers

While other suppliers may provide standard Constantan alloys, DLX focuses on delivering high-performance materials that exceed basic requirements. Generic suppliers often lack the precision and customization needed for aerospace, scientific, and advanced industrial use.

DLX offers tailored solutions, ensuring that every strip of Constantan 6J11 integrates seamlessly into critical applications. This results in reduced downtime, increased reliability, and long-term cost savings for our clients.

The Constantan 6J11 Alloy Strip for Precision Instruments and Resistor Manufacturing is more than just a resistance alloy—it is a cornerstone material enabling industries to achieve accuracy, stability, and durability. Its reliable resistivity and resistance to corrosion make it indispensable in electronics, aerospace, automotive, and renewable energy systems.

DLX remains at the forefront of Constantan 6J11 production, delivering unmatched precision, consistency, and customer support. By combining advanced manufacturing processes with deep technical expertise, we provide not only materials but also solutions that help our clients achieve their goals.

As industries continue to demand higher precision and reliability, DLX is committed to ensuring that our Constantan 6J11 strips deliver the quality and performance that set us apart in the global market.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Constantan 6J11 Strip composed of?

It is composed mainly of copper and nickel, with about 60% copper and 40% nickel.What is the typical resistivity of Constantan 6J11?

Its resistivity is approximately 0.49 Ω·mm²/m.Does Constantan 6J11 perform well under varying temperatures?

Yes, it offers very stable resistance over a broad temperature range.What industries commonly use Constantan 6J11?

Electronics, instrumentation, aerospace, automotive, and industrial manufacturing.Can Constantan 6J11 be welded or processed easily?

Yes, it has good machinability, weldability, and workability.Is Constantan 6J11 corrosion resistant?

Yes, it resists atmospheric oxidation and general corrosion.What applications rely on Constantan 6J11?

Resistors, precision instruments, strain gauges, and industrial sensors.Why should companies choose DLX for Constantan 6J11 Strip?

Because DLX ensures tight tolerances, reliable performance, and tailored solutions for specific applications.