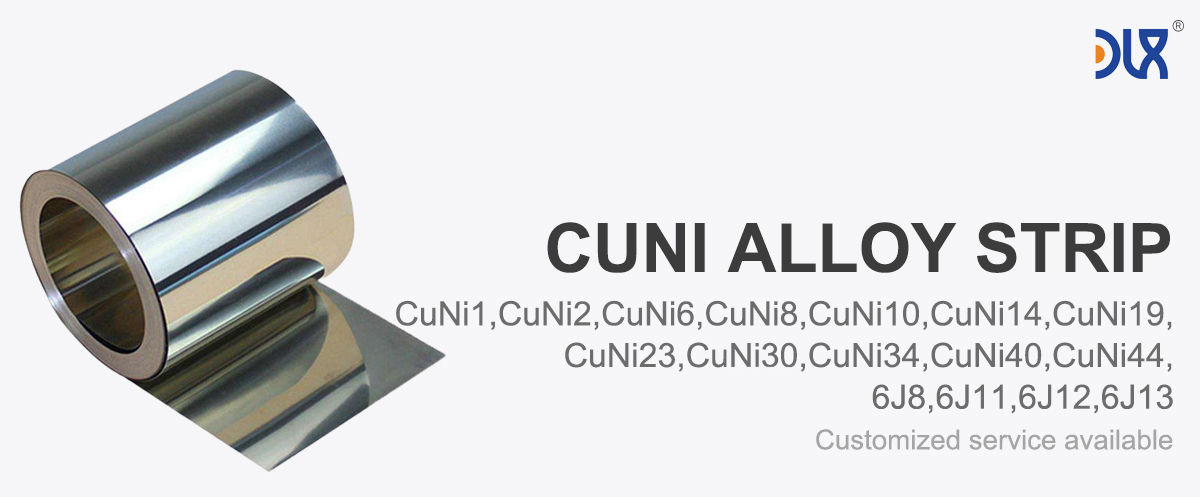

Premium Quality Manganese Bronze 6J13 Strip for Industrial Applications

The Premium Quality Manganese Bronze 6J13 Strip for Industrial Applications represents one of the strongest and most reliable copper alloys available today. Known for its outstanding mechanical performance, this material combines high tensile strength, excellent wear resistance, and solid corrosion resistance. At DLX, we manufacture 6J13 strips with precision and consistency, ensuring they meet the demanding requirements of global industrial sectors.

Manganese Bronze 6J13 is a robust alloy designed for heavy-duty environments. Its ability to endure mechanical stress, resist seawater corrosion, and deliver long service life makes it a preferred material for critical components in industries ranging from shipbuilding and offshore engineering to heavy machinery and power transmission systems.

For more details, pls directly contact us.

The industrial materials market is rapidly evolving as companies demand stronger, more durable, and more cost-efficient materials. With global infrastructure expansion, renewable energy development, and the increasing scale of shipbuilding and offshore projects, the need for high-strength bronze alloys like 6J13 has grown significantly.

In marine and offshore engineering, Manganese Bronze 6J13 is an ideal solution due to its corrosion resistance in saltwater and its toughness under mechanical load. In industrial machinery, it plays a vital role in ensuring reliability, particularly in parts that experience friction, pressure, and wear.

The global focus on sustainability also contributes to the rising use of 6J13. Since this alloy is highly durable and reduces the need for frequent part replacement, it lowers costs and minimizes environmental impact.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

|

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

|

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

|

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

|

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

|

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

The versatility of Manganese Bronze 6J13 Strip is evident in its wide range of uses. Typical applications include:

-

Gears and Transmission Systems: High-load gears and mechanical systems that require both toughness and wear resistance.

-

Bearings and Bushings: Long-lasting parts designed to reduce friction under pressure.

-

Shafts and Couplings: Essential components for machinery, marine propulsion, and power systems.

-

Marine Hardware: Propellers, rudders, and underwater components requiring seawater resistance.

-

Heavy-Duty Industrial Equipment: Machinery parts that must endure stress, vibration, and wear.

-

Offshore Structures: Components exposed to corrosive environments and mechanical load.

-

Renewable Energy Systems: Marine turbines and mechanical equipment exposed to continuous water flow.

-

Defense Applications: Naval and industrial-grade components where strength and durability are critical.

DLX Company Advantages

At DLX, we understand the critical role materials play in industrial and marine engineering. When choosing Manganese Bronze 6J13 Strip, clients are not simply selecting a material—they are investing in reliability, long service life, and consistent performance.

Here’s why DLX is the trusted partner for global industries:

-

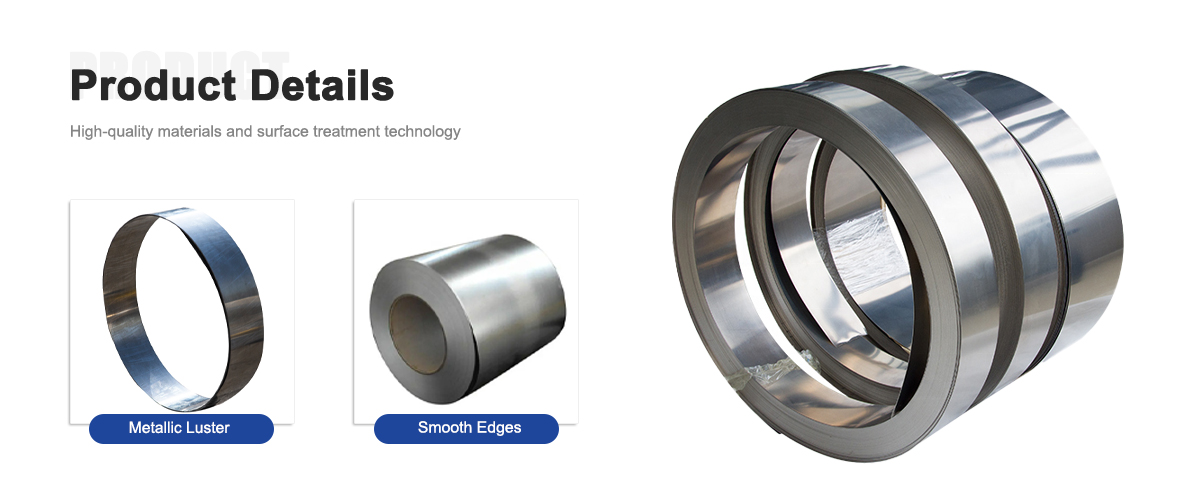

High-Precision Production: Our strips are manufactured with advanced equipment, ensuring dimensional accuracy and mechanical consistency.

-

Custom Specifications: We offer tailored sizes, thicknesses, and finishes to match diverse industrial needs.

-

Quality Assurance: Every batch undergoes rigorous inspection and testing for strength, toughness, and corrosion resistance.

-

Global Reach: With a well-established supply chain, DLX serves clients across different continents with timely delivery.

-

Technical Support: Our team provides expert guidance on material selection, processing, and application integration.

-

Durability Commitment: By sourcing from DLX, industries gain reliable materials that lower downtime and reduce long-term costs.

This customer-first approach ensures that DLX’s Manganese Bronze 6J13 Strip delivers performance advantages far beyond what standard suppliers offer.

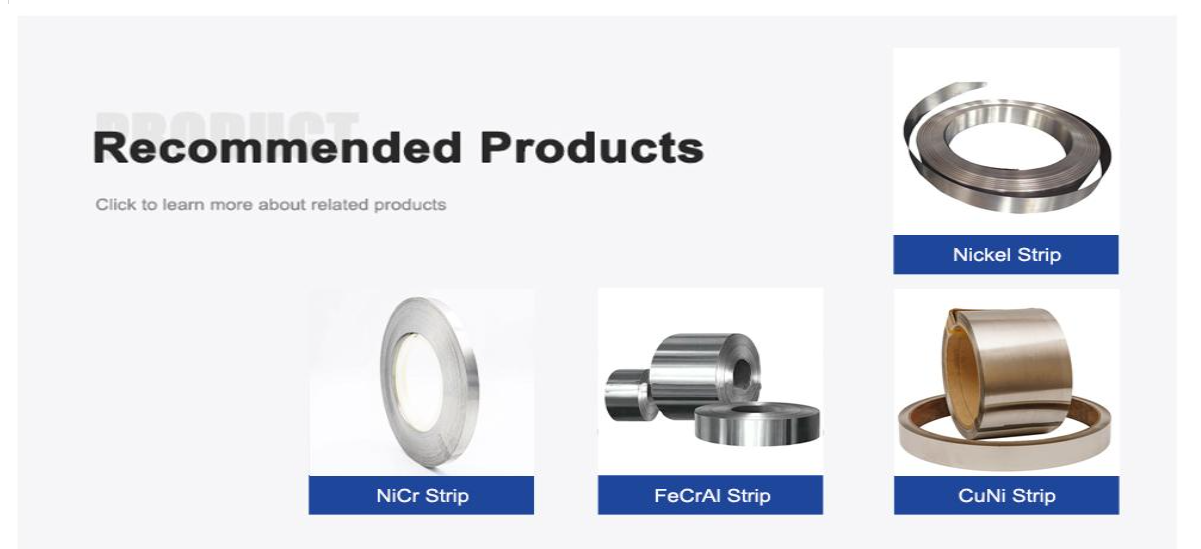

Comparison Table: Manganese Bronze Alloys

| Property | Manganese Bronze 6J13 Strip | Manganese Bronze 6J12 Strip | Manganese Bronze 6J8 Strip | Constantan 6J40 Strip | Constantan 6J11 Strip |

|---|---|---|---|---|---|

| Composition | Cu-Zn-Mn-Fe | Cu-Zn-Mn-Fe | Cu-Zn-Mn | Cu-Ni | Cu-Ni |

| Corrosion Resistance | Very Good in seawater | Excellent in seawater | Good in seawater | Moderate | Moderate |

| Mechanical Strength | Very High | High | Moderate | Moderate | Moderate |

| Wear Resistance | Excellent | Excellent | Good | Low | Low |

| Applications | Industrial gears, bearings, shafts, bushings | Marine parts, offshore equipment | Structural engineering components | Resistors, sensors | Electrical parts |

| Typical Density (g/cm³) | ~8.5 | ~8.4 | ~8.3 | ~8.9 | ~8.9 |

The growing global reliance on high-performance alloys highlights the importance of Manganese Bronze 6J13. Some key trends shaping its demand include:

-

Shipbuilding Growth: Rapid expansion in naval and commercial ship construction boosts demand for seawater-resistant alloys.

-

Offshore Energy Development: Tidal, wind, and offshore drilling projects require strong, corrosion-resistant materials.

-

Industrial Modernization: Heavy machinery and equipment demand durable components that can withstand increasing workloads.

-

Sustainability: Companies are shifting toward materials that extend equipment lifespans, lowering environmental and financial costs.

-

Defense Investments: Naval and defense projects continue to rely on strong, reliable alloys like 6J13 for critical hardware.

These trends confirm that alloys like 6J13 are not just industrial staples—they are strategic enablers of long-term industrial growth.

DLX vs. Other Suppliers

What distinguishes DLX in the global market is our dedication to more than just material supply. While many providers offer generic bronze alloys, DLX delivers tailored solutions engineered for performance.

We combine advanced production techniques with strict quality control, ensuring each 6J13 strip exceeds expectations. Where other suppliers may provide limited customization, DLX works closely with clients to deliver the right specifications for their exact application. This combination of material excellence, flexibility, and customer service makes us the preferred choice for industries worldwide.

The Premium Quality Manganese Bronze 6J13 Strip for Industrial Applications represents the perfect material choice for environments that demand high strength, excellent wear resistance, and reliable corrosion performance.

At DLX, we take pride in producing 6J13 strips that not only meet but exceed industry expectations. With our advanced manufacturing, global logistics network, and client-focused approach, we ensure that every delivery supports the long-term success of our customers.

As industries continue to evolve in shipbuilding, offshore energy, industrial machinery, and defense, DLX remains committed to supplying the materials that drive innovation and reliability. Choosing DLX means choosing durability, consistency, and a trusted partner in progress.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the main composition of Manganese Bronze 6J13 Strip?

It is primarily a copper-zinc alloy with manganese, iron, and other strengthening elements. -

What makes Manganese Bronze 6J13 suitable for industrial applications?

Its high strength, toughness, and excellent resistance to wear and corrosion make it ideal. -

Can Manganese Bronze 6J13 be used in marine environments?

Yes, it offers very good seawater resistance, making it reliable for marine and offshore engineering. -

Does Manganese Bronze 6J13 have good machinability?

Yes, it can be machined efficiently and shaped into complex components. -

What are the main applications of Manganese Bronze 6J13 Strip?

It is commonly used in gears, bearings, shafts, bushings, marine hardware, and heavy-duty machinery. -

How does Manganese Bronze 6J13 compare with 6J12 and 6J8?

It offers higher strength and toughness compared to 6J12 and 6J8, with excellent wear resistance. -

Is Manganese Bronze 6J13 suitable for high-load environments?

Yes, it performs exceptionally well in high-stress, heavy-duty applications. -

Why source Manganese Bronze 6J13 Strip from DLX?

Because DLX guarantees precise production, consistent quality, and tailored solutions for global industries.