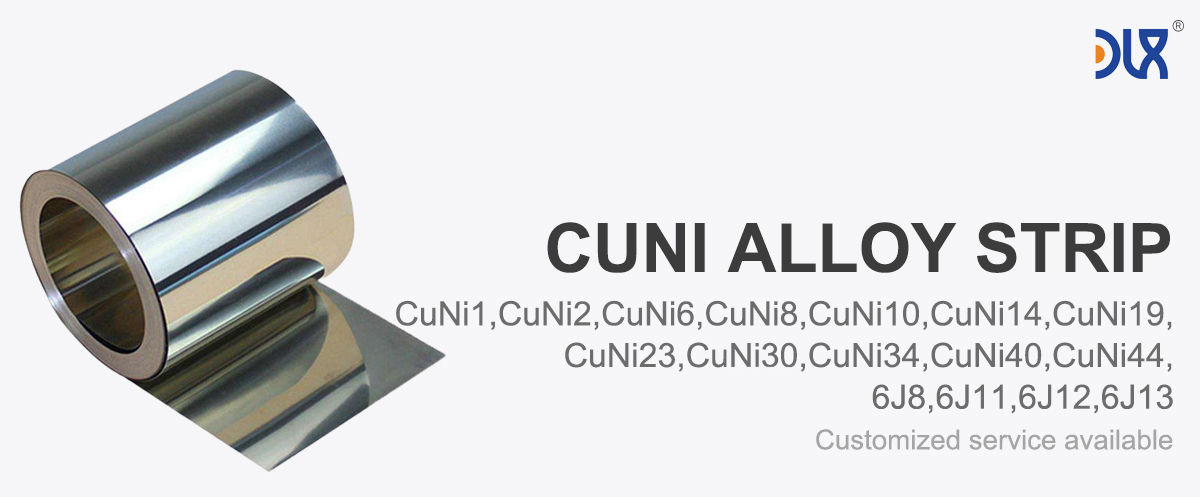

Precision CuNi34 Alloy Strip for Corrosion-Resistant Sensors

Our Precision CuNi34 Alloy Strip is a top-tier material crafted for corrosion-resistant sensors and high-performance electrical components. With a 34% nickel content, this copper-nickel alloy delivers exceptional resistance to corrosion, high thermal stability, and reliable electrical properties. It’s the perfect choice for industries needing sensors that can withstand harsh environments, like marine, chemical processing, and automotive. Available in widths from 0.02mm to 150mm, our strip is designed to meet the most demanding specifications with precision and consistency.

This alloy’s high resistivity—around 40 µΩ·cm at 20°C—makes it ideal for precision sensors and resistors, while its ability to perform at temperatures up to 500°C ensures reliability in extreme conditions. We’ve fine-tuned our production process to deliver a product that not only meets but exceeds industry standards, giving you a material you can trust for long-term performance in corrosive environments.

For more details, pls directly contact us.

The CuNi34 Alloy Strip is a standout for its unique blend of properties. Its 34% nickel content gives it superior corrosion resistance compared to lower-nickel alloys like CuNi10 , making it a go-to for sensors exposed to saltwater, acids, or other aggressive chemicals. Compared to higher-nickel alloys like CuNi44, it’s more cost-effective without sacrificing performance. Its thermal conductivity (30 W/mK) ensures efficient heat dissipation, while its tensile strength (380 MPa) provides durability under mechanical stress.

This alloy’s low temperature coefficient of resistance (TCR) ensures stable electrical properties across a wide temperature range, from -100°C to 500°C. This makes it perfect for sensors in applications where temperature fluctuations are common, like marine monitoring systems or chemical processing plants. Its exceptional resistance to chemical corrosion also means it can handle the toughest environments, ensuring your sensors stay accurate and reliable for years.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 | |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 | |

0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 | |

0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 | |

0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 | |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 | |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

The copper-nickel alloy market is thriving, driven by the growing need for corrosion-resistant materials in marine, automotive, and chemical processing industries. Sensors, in particular, are seeing increased demand as industries adopt advanced monitoring systems to improve efficiency and safety. The global sensor market is projected to grow at a CAGR of around 6.5% through 2030, fueled by advancements in IoT, industrial automation, and environmental monitoring.

Copper-nickel alloys like CuNi34 are at the forefront of this growth. Their ability to resist corrosion in harsh environments makes them essential for sensors used in marine applications, chemical plants, and renewable energy systems. The rise of electric vehicles (EVs) and autonomous driving technologies is also driving demand for reliable sensor materials that can handle high temperatures and corrosive conditions. CuNi34’s high resistivity and durability make it a perfect fit for these applications.

Sustainability is a key trend shaping the industry. Companies are under pressure to use eco-friendly materials, and our CuNi34 strip delivers. Produced with energy-efficient processes, it’s also fully recyclable, helping customers meet environmental goals. The trend toward miniaturization in electronics is another driver, with industries demanding thinner, more precise alloy strips for compact sensor designs. Our ability to produce strips as thin as 0.02mm positions us to meet this growing need.

Emerging technologies, like smart sensors for environmental monitoring and IoT-enabled industrial systems, are increasing the demand for high-performance alloys. These systems require materials that can maintain accuracy in corrosive environments, and CuNi34 is up to the task. As industries continue to innovate, the role of corrosion-resistant alloys in sensor technology will only expand.

Applications of CuNi34 Alloy Strip

Our CuNi34 Alloy Strip is a versatile material with applications across a wide range of industries. Here’s where it makes a difference:

Corrosion-Resistant Sensors: Its superior resistance to chemical and seawater corrosion makes it ideal for sensors in marine monitoring, chemical processing, and environmental monitoring systems.

Precision Resistors: The strip’s high resistivity and stable electrical properties are perfect for resistors in automotive, telecommunications, and medical devices.

Marine Applications: Used in sensors and electrical components for ships, offshore platforms, and desalination systems, it withstands constant exposure to saltwater.

Automotive Systems: From EV battery monitoring sensors to engine control units, CuNi34 ensures reliable performance in high-temperature, corrosive environments.

Chemical Processing: Its resistance to acids and other corrosive chemicals makes it suitable for sensors and components in chemical plants.

Renewable Energy: In wind and tidal energy systems, the strip is used in sensors that require durability in harsh outdoor conditions.

Its flexibility also makes it suitable for custom applications, like low-voltage circuit breakers and conductive elements, where corrosion resistance and thermal stability are critical.

Comparison Table: CuNi34 vs. CuNi14 vs. Other Copper-Nickel Alloys

Property | CuNi34 | CuNi14 | CuNi10 | CuNi44 (Constantan) |

|---|---|---|---|---|

Nickel Content (%) | 34 | 14 | 10 | 44 |

Resistivity at 20°C (µΩ·cm) | 40 | 20 | 15 | 49 |

Max Operating Temp (°C) | 500 | 450 | 300 | 600 |

Thermal Conductivity (W/mK) | 30 | 45 | 50 | 23 |

Tensile Strength (MPa) | 380 | 320 | 250 | 420 |

Corrosion Resistance | Excellent | Excellent | Good | Excellent |

Chemical Corrosion Resistance | Superior | Excellent | Moderate | Excellent |

Applications | Sensors, resistors | Desalination, heat exchangers | Low-temp heating | Precision resistors, thermocouples |

We’re not just a supplier—we’re a leader in delivering high-quality CuNi34 Alloy Strip. Here’s why we stand out:

Unmatched Precision: Our advanced manufacturing ensures strips with tight tolerances, from 0.02mm to 150mm in width, delivering consistent performance for your sensors.

Customizable Solutions: We offer tailored strip sizes and configurations to meet your specific needs, whether for sensors, resistors, or other components.

Rigorous Quality Control: Every batch undergoes extensive testing in our state-of-the-art labs, meeting ASTM and ISO9001 standards for chemical and physical properties.

Global Expertise, Local Support: With over 40 years of experience, we export to more than 70 countries and provide dedicated support to ensure your projects succeed.

Eco-Friendly Production: Our energy-efficient processes and recyclable materials help you meet sustainability goals without compromising quality.

Fast Delivery: Our streamlined production and logistics ensure quick turnaround times, even for custom orders, keeping your projects on schedule.

Compared to others, our focus on precision, customization, and sustainability gives us a clear advantage. We deliver a product that’s tailored to your needs and built to perform in the toughest conditions.

Looking Forward

The future of CuNi34 Alloy Strip is bright. As industries like marine, automotive, and chemical processing continue to grow, the demand for corrosion-resistant, high-performance alloys will soar. We’re committed to staying ahead, investing in R&D to enhance our strip’s properties and meet emerging challenges. From developing thinner strips for compact sensors to improving corrosion resistance for next-generation applications, we’re always innovating.

Our CuNi34 strip is a critical component in the systems driving modern industries. From sensors monitoring ocean conditions to components in EV battery systems, it’s a small but essential part of the bigger picture. We’re excited to support our customers in building reliable, sustainable solutions for the future.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the Precision CuNi34 Alloy Strip used for?

It’s designed for corrosion-resistant sensors, precision resistors, and low-voltage electrical components in industries like marine, automotive, and chemical processing.Why is CuNi34 ideal for corrosion-resistant sensors?

Its high nickel content (34%) provides excellent resistance to corrosion in harsh environments, ensuring reliable sensor performance.Which industries benefit from CuNi34 Alloy Strip?

Marine, automotive, renewable energy, chemical processing, and industrial automation use it for sensors and electrical components.How does CuNi34 compare to other copper-nickel alloys?

CuNi34 offers higher corrosion resistance than CuNi10 and better cost-efficiency than CuNi44, balancing performance and affordability.What are the temperature limits for CuNi34?

It performs reliably from -100°C to 500°C, suitable for extreme temperature sensor applications.Is CuNi34 resistant to chemical corrosion?

Yes, it excels in environments with saltwater, acids, and other corrosive chemicals, making it ideal for sensors in harsh settings.Can CuNi34 be customized for specific sensor designs?

We provide tailored strip sizes, from 0.02mm to 150mm in width, to meet unique project specifications.What’s the lifespan of CuNi34 in sensor applications?

With proper use, it delivers consistent performance for years, even in aggressive corrosive environments.