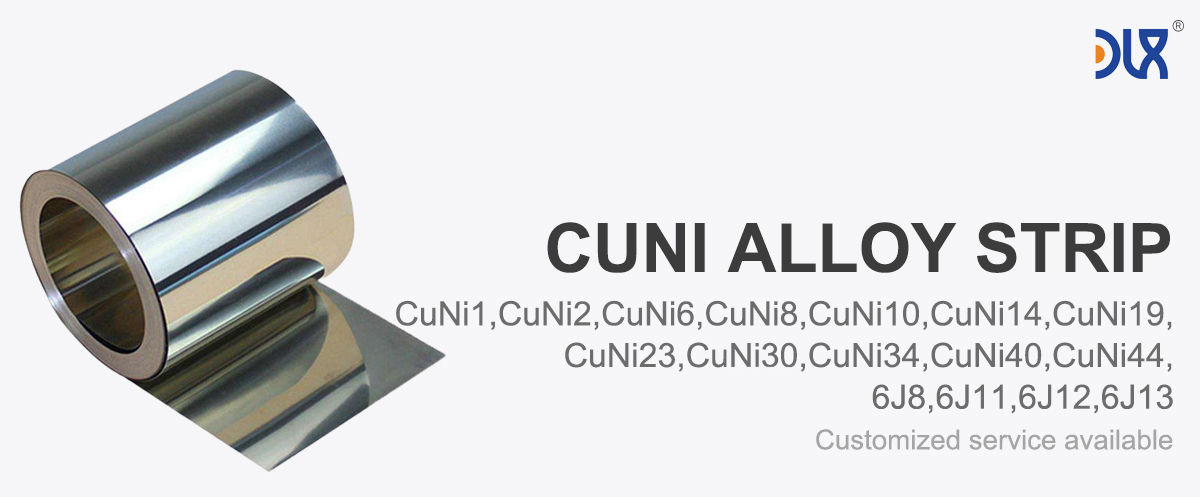

Corrosion-Resistant Manganese Bronze 6J12 Strip for Marine Engineering

The Corrosion-Resistant Manganese Bronze 6J12 Strip for Marine Engineering is a high-strength, durable, and seawater-resistant alloy designed for demanding applications in shipbuilding, offshore systems, and industrial machinery. At DLX, we manufacture 6J12 strips with precision and quality, ensuring they meet international standards for mechanical performance and corrosion resistance.

Manganese Bronze 6J12 offers a unique balance of toughness, wear resistance, and durability, making it an excellent material for heavy-duty environments. Its ability to withstand marine conditions makes it a trusted choice for components such as gears, shafts, bearings, and structural parts in the maritime and engineering industries.

For more details, pls directly contact us.

The global demand for marine-grade alloys is steadily increasing due to the expansion of shipbuilding, offshore drilling, renewable marine energy, and naval defense projects. Industries are actively seeking materials that can provide both mechanical strength and corrosion resistance, especially in saltwater environments.

Manganese Bronze 6J12 fits perfectly into this landscape, offering not only the strength needed for high-load components but also the durability required for long-term exposure to seawater. While stainless steels and other alloys are sometimes used in marine systems, Manganese Bronze provides a better balance of strength, machinability, and resistance to biofouling.

As industrial operations shift toward sustainability and efficiency, materials like 6J12 will see increased adoption because they reduce the frequency of replacement, lower maintenance costs, and extend equipment life cycles.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

|

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

|

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

|

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

|

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

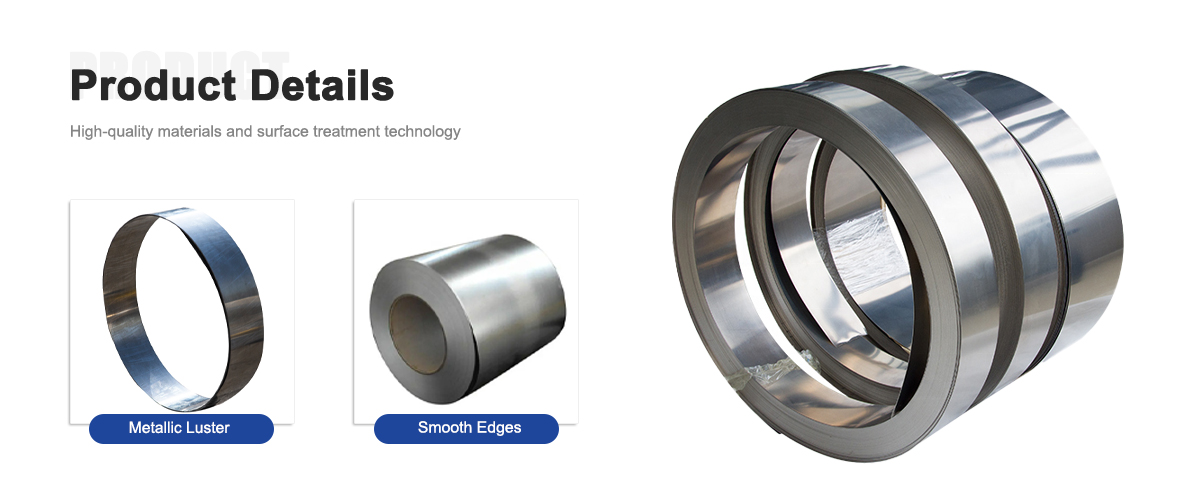

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

The Manganese Bronze 6J12 Strip is widely utilized in both marine and industrial environments due to its versatile properties. Key applications include:

-

Marine Engineering: Propeller shafts, rudders, hull fittings, and underwater fasteners.

-

Shipbuilding: Bearings, bushings, and high-load gears that must resist seawater corrosion.

-

Offshore Platforms: Structural parts that withstand saltwater and mechanical stress.

-

Heavy Industrial Equipment: Gears, couplings, and mechanical components requiring toughness.

-

Oil & Gas: Components in subsea systems exposed to high-pressure and corrosive environments.

-

Defense & Naval Systems: Strong, corrosion-resistant alloys for long-term deployment at sea.

-

Renewable Energy: Marine turbine components exposed to continuous water flow.

-

General Engineering: Shafts, connectors, and wear-resistant parts across industries.

DLX Company Advantages

At DLX, we understand that when clients choose Manganese Bronze 6J12, they expect more than just a strip of metal—they expect a reliable solution that supports performance, efficiency, and longevity. Here is how we stand out:

-

Precision Manufacturing: We apply strict process controls to ensure dimensional accuracy and uniform properties in every strip.

-

Global Supply Capability: From small R&D projects to large-scale industrial orders, DLX delivers consistent quality worldwide.

-

Custom Specifications: We produce strips in a variety of thicknesses, widths, and finishes to suit diverse engineering requirements.

-

Advanced Testing: Each batch undergoes corrosion and mechanical testing to guarantee performance in marine and industrial environments.

-

Customer-Centered Service: We work closely with our clients, offering technical support and supply-chain reliability.

-

Durability Assurance: By sourcing from DLX, clients minimize downtime and reduce long-term operational costs.

This focus on quality and partnership ensures our clients achieve consistent results, even under the toughest conditions.

Comparison Table: Manganese Bronze Strips

| Property | Manganese Bronze 6J12 Strip | Manganese Bronze 6J13 Strip | Manganese Bronze 6J8 Strip | Constantan 6J40 Strip | Constantan 6J11 Strip |

|---|---|---|---|---|---|

| Composition | Cu-Zn-Mn-Fe | Cu-Zn-Mn-Fe | Cu-Zn-Mn | Cu-Ni | Cu-Ni |

| Corrosion Resistance | Excellent in seawater | Very Good in seawater | Good in seawater | Moderate | Moderate |

| Mechanical Strength | High | Very High | Moderate | Moderate | Moderate |

| Wear Resistance | Excellent | Excellent | Good | Low | Low |

| Applications | Marine engineering, gears, bearings | Shipbuilding, offshore parts | Structural components | Resistors, sensors | Electrical components |

| Typical Density (g/cm³) | ~8.4 | ~8.5 | ~8.3 | ~8.9 | ~8.9 |

Manganese Bronze 6J12 is aligned with several global industrial trends:

-

Marine Renewable Energy: Growth in tidal and offshore wind projects increases demand for durable, seawater-resistant materials.

-

Shipbuilding Expansion: Asia and Europe are leading in naval and commercial vessel construction, driving usage of corrosion-resistant alloys.

-

Sustainable Engineering: Longer-lasting materials help companies meet sustainability goals by reducing replacement cycles.

-

Defense Applications: Increasing investments in naval defense require alloys like 6J12 for durability and strength.

-

Offshore Oil & Gas Projects: Deep-sea exploration continues to rely on high-strength, corrosion-resistant alloys.

These trends highlight the strategic role of alloys like Manganese Bronze 6J12 in global industrial and marine development.

DLX vs. Other Suppliers

While many suppliers provide basic bronze alloys, DLX goes further. Our Manganese Bronze 6J12 Strip is engineered to deliver consistent performance, even in the harshest environments. Competitors may offer standard materials, but DLX focuses on delivering tailored solutions backed by rigorous testing, advanced production methods, and reliable global logistics.

Clients choosing DLX are not only purchasing a material—they are investing in stability, efficiency, and a long-term partnership with a supplier that understands the challenges of marine and industrial sectors.

The Corrosion-Resistant Manganese Bronze 6J12 Strip for Marine Engineering represents the perfect balance of mechanical strength, toughness, and seawater durability. Its unique composition ensures long-lasting performance in environments where both high load-bearing capacity and corrosion resistance are essential.

At DLX, we take pride in delivering 6J12 strips that exceed client expectations. With advanced manufacturing, global supply reach, and a commitment to customer satisfaction, we provide more than material—we deliver trust and reliability.

As industries continue to advance in shipbuilding, renewable energy, offshore exploration, and heavy engineering, DLX remains ready to supply the materials that keep progress moving forward. By choosing DLX, clients secure not just a supplier, but a dedicated partner in performance and durability.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is the main composition of Manganese Bronze 6J12 Strip?

It is a copper-zinc alloy with added manganese, iron, and small elements for enhanced properties. -

What makes Manganese Bronze 6J12 corrosion-resistant?

The alloying with manganese improves strength and provides excellent resistance to seawater and industrial atmospheres. -

Where is Manganese Bronze 6J12 commonly used?

It is widely applied in marine engineering, shipbuilding, offshore structures, and heavy-duty industrial equipment. -

Does Manganese Bronze 6J12 have good mechanical strength?

Yes, it combines high strength with toughness and excellent wear resistance. -

Can Manganese Bronze 6J12 be welded or machined?

Yes, it has good machinability and can be welded with suitable techniques. -

How does Manganese Bronze 6J12 compare to other copper alloys?

It provides higher strength and better seawater resistance compared to many standard copper-zinc alloys. -

Is Manganese Bronze 6J12 suitable for high-load applications?

Yes, its mechanical performance makes it ideal for gears, bearings, shafts, and heavy-duty marine parts. -

Why should I source Manganese Bronze 6J12 Strip from DLX?

Because DLX ensures precision manufacturing, consistent quality, and customized supply options for global clients.