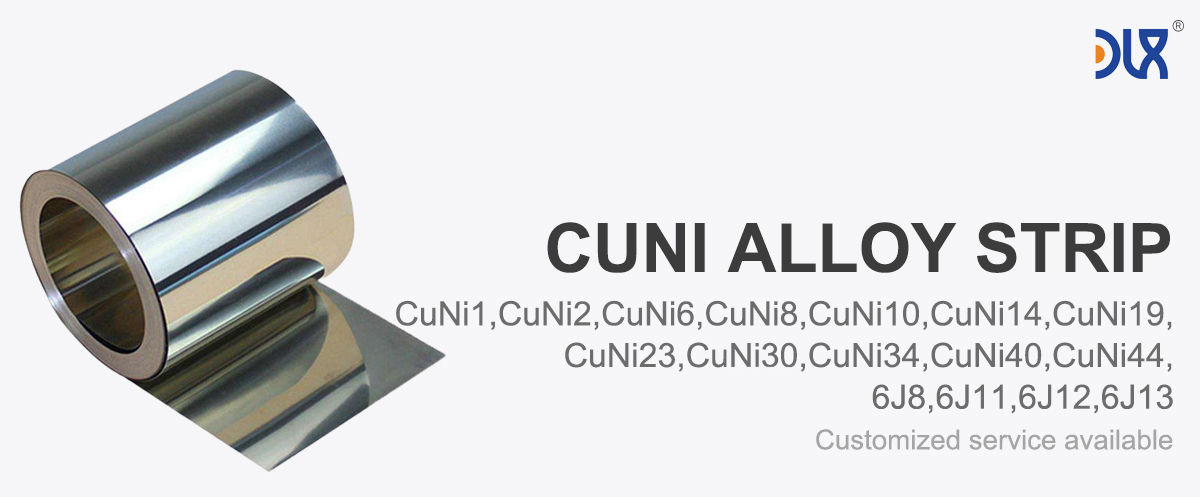

CuNi10 Strip for Corrosion-Resistant Marine Applications

Our CuNi1 0 strip is a superstar for marine applications, built to take on the toughest saltwater environments without flinching. This copper-nickel alloy, with 10% nickel and often a bit of iron (CuNi10Fe), is our go-to for projects where corrosion resistance and reliability are critical.

For more details, pls directly contact us.

The big deal with CuNi10 strip is its ability to stand up to seawater like nobody’s business. It’s perfect for marine heat exchangers, ship wiring, desalination components, and corrosion-resistant fittings. The iron in CuNi10Fe gives it an extra layer of protection against rust, so your marine systems keep humming even in the saltiest conditions. Plus, it’s got solid electrical conductivity—around 20% IACS—making it great for marine electrical applications where performance can’t falter.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 | |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 | |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

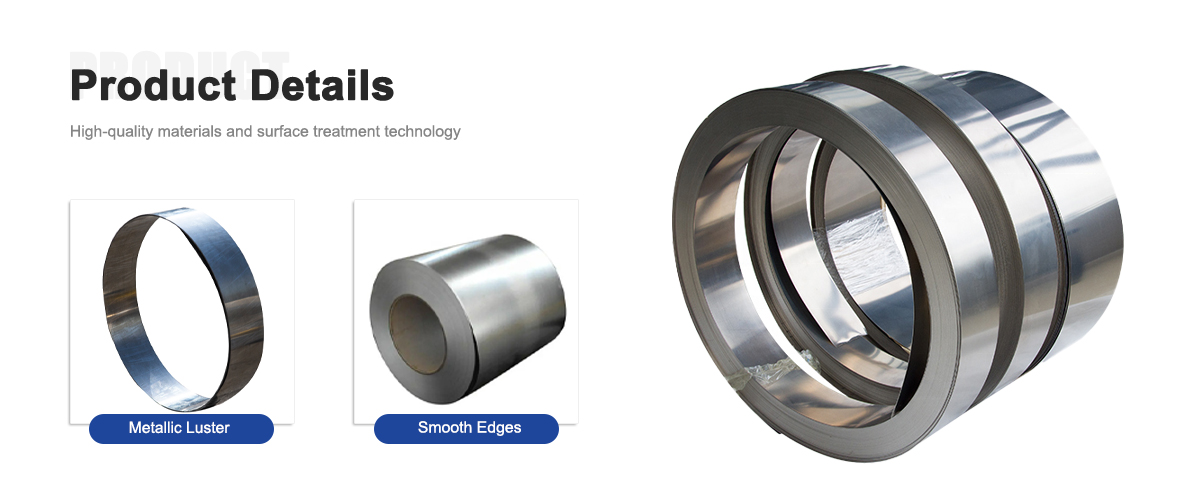

This strip is a breeze to work with. Its awesome formability means you can shape, weld, or roll it into whatever your project needs—thin strips for wiring or wider ones for heat exchanger plates. Need a custom thickness or width? We can tailor it to fit your specs, making manufacturing smooth and hassle-free. It’s also stable up to 400°C, so it handles the heat in marine systems without breaking a sweat.

The industry’s all about materials that are tough, sustainable, and cost-effective, and CuNi10 strip checks every box. It’s recyclable, which is a win for eco-friendly projects, and its long lifespan means fewer replacements and less waste. With marine industries growing—think offshore wind farms, shipping, and desalination—demand for corrosion-resistant materials like CuNi10 is through the roof. Energy efficiency is a hot trend too, and this strip’s reliability in heat exchangers supports greener marine operations.

Compared to other materials, CuNi10 strip holds its own. Pure copper’s a conductivity champ but corrodes fast in seawater. CuNi30Mn has better corrosion resistance and heat tolerance but lower conductivity and higher cost, making CuNi10 a great balance for marine applications. Stainless steel’s strong but doesn’t match CuNi10’s seawater resistance or formability. This strip is the perfect pick for marine durability.

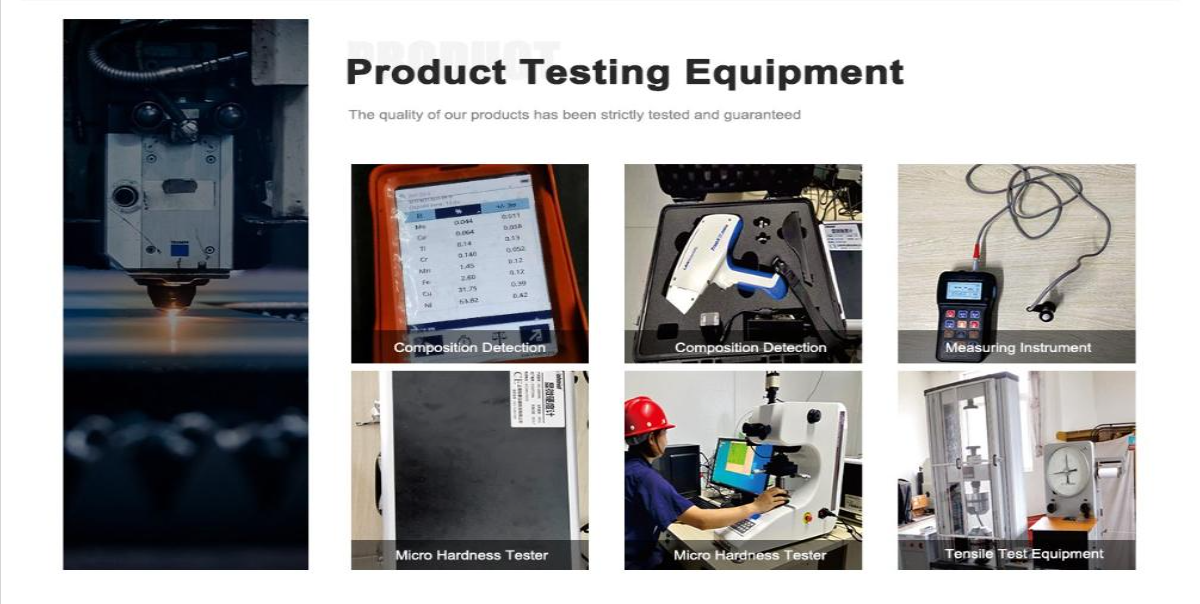

We produce our CuNi10 strip to meet strict standards like ISO 9001, so you’re getting quality you can trust every time. Whether you’re wiring ships or building desalination systems, this strip’s ready to perform. Got a specific need? Let us know, and we’ll make it happen.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is CuNi10 strip made of?

It’s a copper-nickel alloy with 10% nickel, often with iron (CuNi10Fe) to enhance corrosion resistance.What are the main uses for CuNi10 strip in marine applications?

It’s used in marine heat exchangers, ship wiring, desalination components, and corrosion-resistant fittings.How does CuNi10 strip perform in seawater?

It’s outstanding, resisting saltwater corrosion, making it ideal for marine and coastal environments.Can CuNi10 strip handle high temperatures?

Yes, it’s stable up to about 400°C, suitable for marine heat exchangers and low-temperature systems.Is CuNi10 strip cost-effective?

It’s pricier than pure copper, but its durability and low maintenance in marine settings save costs long-term.How does CuNi10 strip compare to CuNi30Mn strip?

CuNi10 has higher electrical conductivity but slightly less corrosion resistance and thermal stability than CuNi30Mn.Can CuNi10 strip be customized?

Definitely! We can adjust thickness, width, or supply it in various forms to meet specific marine needs.Is CuNi10 strip environmentally friendly?

It’s recyclable, supporting sustainable practices, and its long lifespan reduces waste from replacements.