Precision CuNi19 Copper Nickel Strip for Thermocouples

We’re proud to offer our Precision CuNi19 Copper Nickel Strip, a high-performance material designed specifically for thermocouple applications and low-voltage electrical systems. This copper-nickel alloy, with 19-23% nickel content, strikes a perfect balance between resistivity, thermal stability, and durability. It’s a go-to choice for industries needing reliable temperature measurement and corrosion-resistant solutions. Whether you’re building thermocouples for industrial automation or designing heating cables for renewable energy systems, our CuNi19 strip delivers consistent performance.

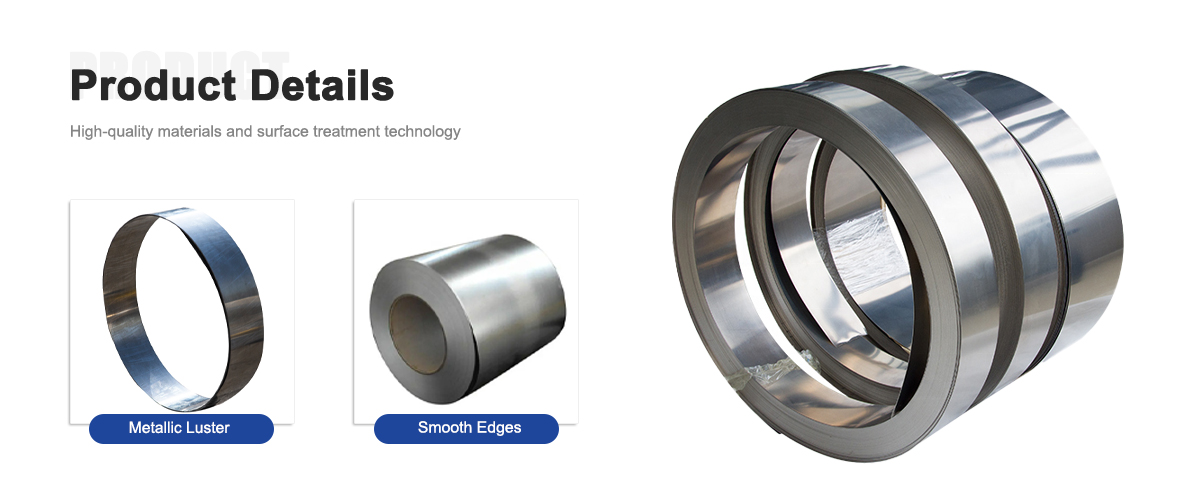

Our strip is engineered with precision, available in widths from 0.05mm to 200mm, and crafted to meet the exacting demands of modern industries. Its medium-low resistivity makes it ideal for applications where efficiency and accuracy are non-negotiable. Plus, it’s built to withstand temperatures up to 400°C while maintaining excellent corrosion resistance, even in harsh environments like sulfur or sulfide-heavy settings. We’ve fine-tuned our manufacturing process to ensure every strip meets strict quality standards, giving you a product you can trust for years.

For more details, pls directly contact us.

The magic of CuNi19 lies in its composition. With a nickel content of 19-23%, it offers a sweet spot for resistivity—around 25-30 µΩ·cm at 20°C—making it versatile for thermocouples like Type T, J, E, and KCB. Unlike alloys with lower nickel content, like CuNi10 , it provides better thermal stability, and compared to higher-nickel alloys like CuNi44 (Constantan), it’s more cost-effective for applications that don’t require extreme resistivity. Its thermal conductivity (38 W/mK) ensures efficient heat transfer, while its tensile strength (340 MPa) guarantees durability under stress.

This alloy’s low temperature coefficient of resistance (TCR) ensures stable performance across a wide temperature range, from -200°C to 400°C. For thermocouple applications, this means accurate readings even in fluctuating conditions. And let’s not forget its corrosion resistance—CuNi19 holds up in environments that would degrade lesser materials, making it a favorite for industries like marine engineering and chemical processing.

Parameter:

|

Properties Material |

Resistivity 200c μΩ.m |

Max working temperature (℃) |

Tensile strength (Mpa) |

Melting point (℃) |

Density (g/cm3) |

TCR *10-6/℃ (20-600℃) |

EMF vs Cu (μV/℃) (0-100℃) |

|

CuNi1 |

0.03 |

200 |

210 |

1085 |

8.9 |

<100 |

-8 |

|

0.05 |

200 |

220 |

1090 |

8.9 |

<120 |

-12 |

|

|

0.1 |

220 |

250 |

1095 |

8.9 |

<60 |

-18 |

|

|

0.12 |

250 |

270 |

1097 |

8.9 |

<57 |

-22 |

|

|

0.15 |

250 |

290 |

1100 |

8.9 |

<50 |

-25 |

|

|

0.2 |

300 |

310 |

1115 |

8.9 |

<30 |

-28 |

|

|

0.25 |

300 |

340 |

1135 |

8.9 |

<25 |

-32 |

|

|

CuNi23 |

0.3 |

300 |

350 |

1150 |

8.9 |

<16 |

-34 |

|

0.35 |

350 |

400 |

1170 |

8.9 |

<10 |

-37 |

|

|

0.4 |

350 |

400 |

1180 |

8.9 |

0 |

-39 |

|

|

CuNi44 |

0.5 |

400 |

420 |

1200 |

8.9 |

<-6 |

-43 |

|

Size Range |

|

|

Wire |

0.08-7.5mm |

|

Ribbon |

(0.05-0.35)*(0.5-6.0)mm |

|

Strip |

(0.50-2.5)*(5-180)mm |

|

Rod |

8-50mm |

For more details, pls directly contact us.

The copper-nickel alloy market is thriving, driven by demand for reliable materials in electronics, automotive, aerospace, and renewable energy sectors. Thermocouples, in particular, are seeing increased adoption as industries prioritize precision temperature monitoring to optimize processes and ensure safety. The global thermocouple market is projected to grow steadily, with a compound annual growth rate (CAGR) of around 5% through 2030, fueled by advancements in industrial automation and the push for energy-efficient systems.

Copper-nickel alloys like CuNi19 are at the heart of this growth. Their versatility makes them indispensable in applications beyond thermocouples, such as heating cables, shunt resistors, and low-voltage circuit breakers. The rise of electric vehicles (EVs) and renewable energy systems, like solar and wind, has further boosted demand for materials that can handle high temperatures and corrosive environments. For instance, heating elements in EVs require alloys with low resistivity and high durability—exactly what CuNi19 delivers.

Sustainability is another key trend shaping the industry. Manufacturers are under pressure to produce eco-friendly materials with minimal environmental impact. Our CuNi19 strip is produced with energy-efficient processes, and its long lifespan reduces the need for frequent replacements, aligning with the industry’s shift toward greener solutions. Additionally, the alloy’s recyclability makes it a smart choice for companies looking to meet sustainability goals.

Emerging technologies, like smart grids and IoT-enabled industrial systems, are also driving demand for precision alloys. These systems rely on accurate sensors, where thermocouples made with CuNi19 play a critical role. As industries move toward automation and real-time monitoring, the need for reliable, high-performance materials will only grow.

Applications of CuNi19 Copper Nickel Strip

Our CuNi19 Copper Nickel Strip is a workhorse across multiple industries. Here’s a closer look at where it shines:

-

Thermocouples: As the negative conductor in Type T, J, E, and KCB thermocouples, CuNi19 ensures precise temperature measurements in applications ranging from laboratory research to industrial furnaces. Its low Seebeck coefficient (around 8 μV/K) makes it ideal for Type T thermocouples, which are widely used in HVAC and food processing.

-

Heating Cables: With its medium-low resistivity and ability to operate at temperatures up to 400°C, the strip is perfect for flexible heating elements in electric blankets, underfloor heating, and automotive systems.

-

Low-Voltage Electrical Components: CuNi19 is a key material in circuit breakers, thermal overload relays, and shunt resistors, where its stability and corrosion resistance ensure long-term reliability.

-

Renewable Energy: In solar and wind energy systems, the strip is used in sensors and heating elements that require durability in outdoor, corrosive environments.

-

Marine and Chemical Industries: Its resistance to corrosion makes it a top choice for applications exposed to saltwater or chemical vapors, such as marine sensors and chemical processing equipment.

The strip’s versatility doesn’t stop there. It’s also used in precision resistors, controllers, and fuses, where its consistent electrical properties and high tensile strength make it a reliable performer.

Comparison Table: CuNi19 vs. CuNi23 vs. Other Copper-Nickel Alloys

|

Property |

CuNi19 |

CuNi23 |

CuNi10 |

CuNi44 (Constantan) |

|---|---|---|---|---|

|

Nickel Content (%) |

19 |

23 |

10 |

44 |

|

Resistivity at 20°C (µΩ·cm) |

25 |

30 |

15 |

49 |

|

Max Operating Temp (°C) |

400 |

400 |

300 |

600 |

|

Thermal Conductivity (W/mK) |

38 |

38 |

50 |

23 |

|

Tensile Strength (MPa) |

340 |

340 |

250 |

420 |

|

Corrosion Resistance |

Excellent |

Excellent |

Good |

Excellent |

|

Thermocouple Types |

T, J, E, KCB |

T, J, E, KCB |

Limited use |

T, J, E |

|

Applications |

Heating, resistors, thermocouples |

Heating, resistors, thermocouples |

Low-temp heating |

Precision resistors, thermocouples |

We’re not just another supplier—we’re a partner you can count on for top-quality CuNi19 Copper Nickel Strip. Here’s why we stand out:

-

Unmatched Precision: Our advanced manufacturing process ensures every strip meets tight tolerances, with widths as narrow as 0.05mm and consistent resistivity across batches. This precision translates to better performance in your applications.

-

Customization Options: Need a specific size or configuration? We offer tailored solutions to match your exact requirements, whether it’s for thermocouples, heating cables, or resistors.

-

Rigorous Quality Control: From raw material selection to final testing, we monitor every step to ensure our strips meet international standards like ASTM and ISO9001. Our in-house chemical and physical testing labs guarantee consistency.

-

Global Reach, Local Support: With over 35 years of experience, we’ve built a global network, exporting to more than 60 countries. Our dedicated support team is always ready to assist, no matter where you are.

-

Sustainability Focus: Our production processes prioritize energy efficiency, and our recyclable CuNi19 strips help you meet environmental goals without sacrificing performance.

-

Fast Turnaround: We know time is money. Our streamlined production and logistics ensure quick delivery, even for custom orders, so your projects stay on track.

Compared to others in the market, our focus on precision, customization, and sustainability gives us an edge. We don’t just sell a product—we deliver a solution that’s tailored to your needs and built to last.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Precision CuNi19 Copper Nickel Strip used for?

It’s primarily used as the negative conductor in thermocouples (Type T, J, E, and KCB) for accurate temperature measurement in industries like HVAC, aerospace, and energy. -

What are the key properties of CuNi19?

It offers medium-low resistivity, excellent corrosion resistance, and stability at temperatures up to 400°C, making it ideal for low-voltage and heating applications. -

What industries rely on CuNi19 Copper Nickel Strip?

Industries like electronics, automotive, renewable energy, and industrial automation use it for thermocouples, heating cables, and resistors. -

How does CuNi19 compare to other copper-nickel alloys?

CuNi19 has a balanced nickel content (19-23%), offering a good mix of resistivity and thermal stability compared to lower or higher nickel alloys like CuNi10 or CuNi44. -

What are the temperature limits for CuNi19?

It operates reliably from -200°C to 400°C, with some applications extending down to 20 K for specific thermocouple types. -

Is CuNi19 suitable for corrosive environments?

Yes, its copper-nickel composition provides excellent corrosion resistance, especially in sulfur and sulfide environments. -

Can CuNi19 be customized for specific applications?

Absolutely, we offer tailored strip sizes, from 0.05mm to 200mm in width, to meet unique project needs. -

What’s the typical lifespan of CuNi19 in thermocouple applications?

With proper use, it maintains stability and accuracy for years, even in demanding industrial settings.