ASTM B575 UNS N06022 Hastelloy C22 Sheet for Marine and Petrochemical Use

In highly demanding industries where exposure to aggressive chemicals, seawater, and extreme temperatures is routine, material selection determines the reliability and safety of entire systems. Among the most advanced materials available, Hastelloy C22 Sheet (UNS N06022) is recognized as a versatile nickel-chromium-molybdenum alloy offering exceptional resistance to both oxidizing and reducing environments. At DLX, we supply high-quality C22 Sheets that meet ASTM B575 standards, delivering consistent performance for marine, petrochemical, chemical processing, aerospace, and pollution control industries.

For more details, pls directly contact us.

Hastelloy C22 is part of a family of nickel-based alloys engineered to endure the harshest industrial environments. Its carefully balanced composition—primarily nickel with significant additions of chromium, molybdenum, and tungsten—provides superior protection against localized corrosion, such as pitting and crevice attack, while also preventing stress corrosion cracking.

Sheets manufactured from C22 are used in pressure vessels, tanks, heat exchangers, piping systems, and structural components. Their formability and weldability make them highly versatile, while their resistance to multiple types of chemical attacks makes them suitable for applications that require long-term reliability. DLX ensures that every Hastelloy C22 Sheet is manufactured to strict tolerances, tested for mechanical and chemical integrity, and delivered in the exact specifications our clients require.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Hastelloy C22 Sheets are widely adopted across industries where performance under extreme conditions is non-negotiable:

-

Marine Industry: C22 is highly resistant to chloride-induced corrosion, making it ideal for desalination plants, ship components, offshore drilling equipment, and seawater piping systems.

-

Petrochemical Sector: Refineries and processing plants use C22 Sheets for reactors, scrubbers, and containment vessels exposed to hydrocarbons and aggressive chemicals.

-

Chemical Processing: Equipment like evaporators, heat exchangers, and piping systems benefit from C22’s broad-spectrum corrosion resistance.

-

Aerospace: Components that must endure corrosive atmospheres and elevated temperatures find reliability in C22 Sheet applications.

-

Pollution Control: Flue gas scrubbers, stack liners, and environmental equipment use this alloy to withstand highly corrosive byproducts.

The adaptability of C22 Sheets to different corrosive environments sets them apart as one of the most reliable materials in high-performance engineering.

Today’s industries are under increasing pressure to perform safely, efficiently, and sustainably. As regulations tighten and operations expand into more challenging environments, demand for advanced alloys like Hastelloy C22 continues to grow.

-

Marine Expansion: With the growth of desalination plants and offshore projects, corrosion-resistant materials are critical for long-term reliability.

-

Petrochemical Growth: New facilities and the modernization of existing refineries require high-performance materials for critical process equipment.

-

Environmental Regulations: Pollution control systems must meet stricter requirements, driving demand for alloys that resist aggressive scrubbing environments.

-

Aerospace Advancements: Modern aircraft and space technologies rely on materials capable of withstanding both mechanical and chemical stress.

-

Global Chemical Processing: Expanding capacity in Asia and the Middle East creates strong demand for durable and high-performance alloys.

This industry landscape makes C22 Sheets one of the most valuable materials for future-oriented infrastructure and advanced systems.

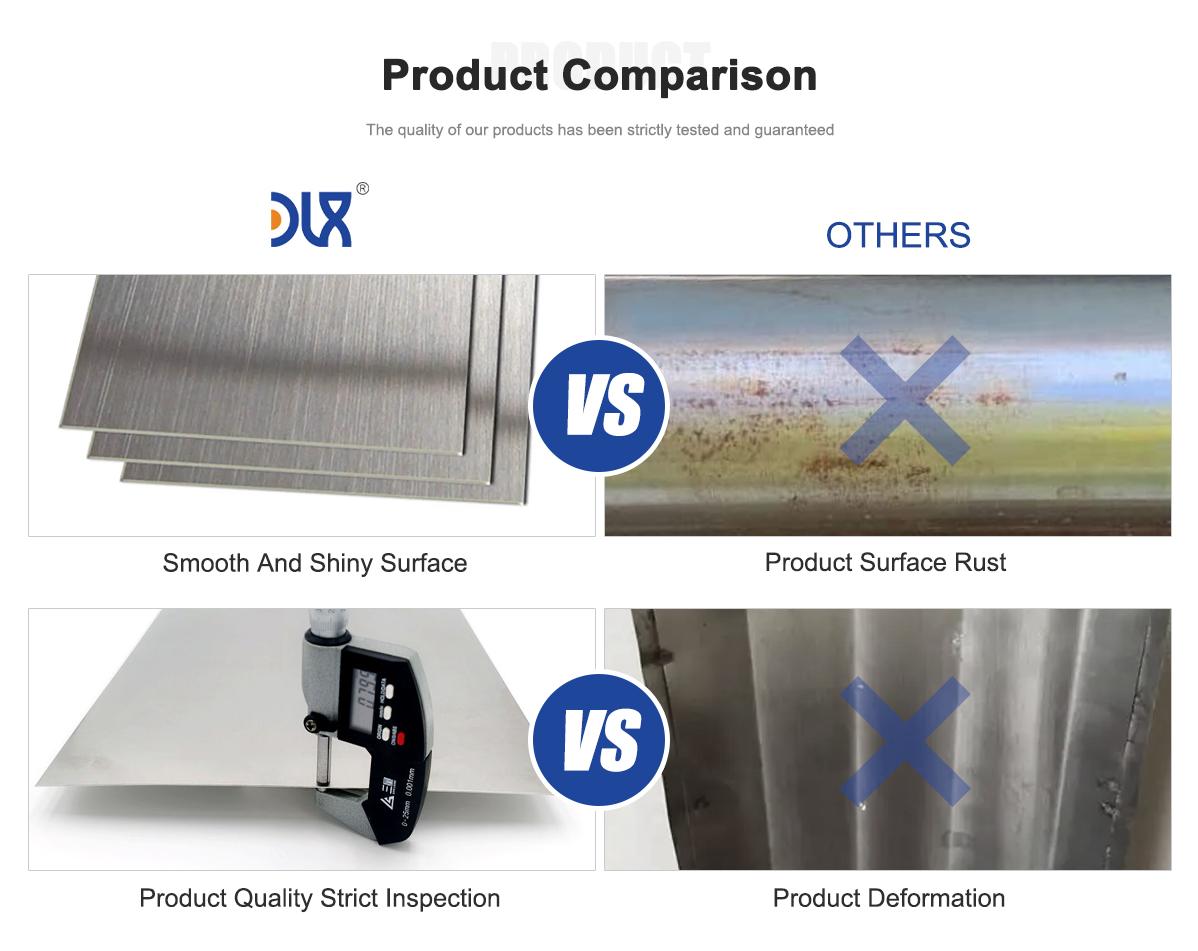

DLX Advantage

Comparison Table: Hastelloy C22 Sheet vs Other Alloys

| Property | Hastelloy C22 Sheet (UNS N06022) | Hastelloy C276 Sheet (UNS N10276) | Stainless Steel 316L Sheet |

|---|---|---|---|

| Base Material | Nickel-Chromium-Molybdenum Alloy | Nickel-Chromium-Molybdenum-Tungsten | Iron-Nickel-Chromium |

| Oxidizing Resistance | Excellent | Very Good | Moderate |

| Reducing Resistance | Very Good | Excellent | Limited |

| Marine Resistance | Excellent | Excellent | Moderate |

| High-Temperature Strength | Excellent | Excellent | Moderate |

| Weldability | Good | Good | Excellent |

| Pitting/Crevice Resistance | Excellent | Very Good | Limited |

| Applications | Marine, petrochemical, aerospace, pollution control | Chemical, petrochemical, pollution control, aerospace | Food, mild chemicals |

| Temperature Range | Up to ~1000°C | Up to ~1000°C | Up to ~870°C |

| Cost Level | Higher | Higher | Lower |

DLX has positioned itself as a reliable global supplier of Hastelloy C22 Sheets, offering more than just raw materials. Our strength lies in delivering solutions tailored to customer needs:

-

ASTM B575 Compliance: Every sheet meets international material standards.

-

Custom Specifications: Thickness, width, and finish tailored to customer requirements.

-

Rigorous Testing: Mechanical properties, chemical composition, and corrosion resistance are verified before dispatch.

-

Technical Expertise: Our team provides welding and fabrication support to maximize material performance.

-

Global Reach: DLX maintains efficient supply chains to ensure on-time delivery worldwide.

-

Reliable Service: Customer satisfaction is at the core of our operations, ensuring smooth project execution.

Our consistent quality and commitment to long-term partnerships make DLX a trusted source for industries requiring high-performance nickel alloys.

When considering material selection, it’s important to compare options. Stainless Steel 316L, while cost-effective, cannot withstand the extreme oxidizing and chloride-rich conditions faced in marine and petrochemical environments. Hastelloy C276 remains a versatile option, but C22 provides superior protection in oxidizing environments and is often preferred for mixed chemical exposure.

DLX’s expertise ensures customers receive tailored recommendations, balancing performance, cost, and long-term reliability. By offering Hastelloy C22 Sheets, we provide a solution that surpasses traditional materials in the harshest conditions.

The global market for corrosion-resistant alloys is expanding rapidly. With the continued development of petrochemical facilities, stricter environmental control systems, and the push for sustainable marine infrastructure, the demand for Hastelloy C22 Sheets is expected to grow steadily.

-

Marine sector investment is projected to rise, especially in desalination and offshore energy.

-

Petrochemical demand remains strong in emerging economies.

-

Environmental infrastructure is a growing priority worldwide.

DLX is strategically positioned to meet this demand with efficient supply, competitive pricing, and uncompromising quality.

Conclusion

ASTM B575 UNS N06022 Hastelloy C22 Sheet is an essential material for industries operating in aggressive chemical, marine, and high-temperature environments. Its combination of nickel, chromium, molybdenum, and tungsten ensures unmatched resistance to pitting, crevice, and stress corrosion cracking.

DLX supplies Hastelloy C22 Sheets with strict quality assurance, customized solutions, and global reliability. With a deep understanding of industry needs and a commitment to performance, DLX ensures our customers gain a competitive edge through materials that deliver long-term value and security.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is Hastelloy C22 Sheet?

A1: It is a nickel-chromium-molybdenum alloy sheet known for its superior resistance to oxidizing and reducing chemical environments.

Q2: What standards does Hastelloy C22 Sheet meet?

A2: It complies with ASTM B575 and UNS N06022 standards.

Q3: What industries commonly use Hastelloy C22 Sheets?

A3: Marine engineering, petrochemical, chemical processing, aerospace, and pollution control.

Q4: Why is Hastelloy C22 ideal for marine use?

A4: It provides excellent resistance to seawater, chlorides, and crevice corrosion.

Q5: Can Hastelloy C22 Sheets be welded and fabricated easily?

A5: Yes, they offer good weldability and formability without risk of grain boundary precipitation.

Q6: How does Hastelloy C22 compare to Hastelloy C276 in sheet form?

A6: C22 has better resistance to oxidizing environments, while C276 provides balanced resistance for both oxidizing and reducing conditions.

Q7: What temperature range can Hastelloy C22 Sheets withstand?

A7: They perform reliably in temperatures up to approximately 1000°C.

Q8: Why should customers choose DLX for Hastelloy C22 Sheets?

A8: DLX ensures ASTM-compliant products, strict quality control, customization, and global delivery with reliable service.