Hastelloy B-2 Plate: Nickel-Molybdenum Alloy for Acid-Resistant Applications

In today’s industrial world, selecting the right material can make the difference between long-term success and frequent maintenance problems. When dealing with aggressive reducing environments, especially hydrochloric acid, Hastelloy B-2 Plate has earned a reputation as a material that ensures reliability and durability. At DLX, we are committed to providing our clients with top-quality Hastelloy B-2 Plates, manufactured in compliance with ASTM standards and tailored to meet the demands of critical industries.

For more details, pls directly contact us.

Hastelloy B-2 Plate (UNS N10665) is a nickel-molybdenum alloy designed specifically to resist aggressive reducing agents. It provides excellent resistance to hydrochloric acid across all concentrations and temperatures, as well as other strong acids like sulfuric and phosphoric acids under reducing conditions. Its metallurgical stability helps prevent issues such as grain boundary carbide precipitation, which can compromise performance in lesser alloys.

This material is ideal for plate fabrication because it maintains strength and corrosion resistance after welding and forming. DLX supplies Hastelloy B-2 Plates in a wide range of thicknesses and dimensions, ensuring versatility for different industrial applications.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

The unique properties of Hastelloy B-2 Plates make them essential for industries where acid resistance is a priority:

-

Chemical Processing: Used in reactors, heat exchangers, evaporators, and pipelines handling hydrochloric acid.

-

Petrochemicals: Deployed in environments where strong reducing agents are common.

-

Pharmaceutical Industry: Offers safe, acid-resistant materials for processing and sterilization equipment.

-

Pollution Control: Provides reliable performance in systems exposed to acidic waste streams.

-

Power Generation: Suitable for certain flue gas scrubbers and acid-handling systems.

By selecting DLX’s Hastelloy B-2 Plates, companies can significantly reduce downtime, extend equipment life, and improve overall safety in harsh conditions.

Industries worldwide are facing increasing challenges due to stricter regulations, higher process temperatures, and more aggressive chemicals. This has driven demand for high-performance materials such as Hastelloy B-2 Plates. Several key trends highlight why this alloy is becoming more important:

-

Chemical Industry Expansion: Modern chemical plants require advanced materials to handle aggressive acids safely.

-

Pharmaceutical Growth: Equipment must meet higher purity and corrosion-resistance standards, making Hastelloy B-2 an attractive option.

-

Petrochemical Development: Strong reducing environments demand alloys that maintain stability and strength.

-

Environmental Regulations: Stricter pollution control measures require reliable acid-resistant materials for waste treatment.

-

Global Infrastructure Investments: Expansion in Asia and the Middle East is creating demand for advanced corrosion-resistant alloys.

In each of these cases, Hastelloy B-2 Plates offer a proven, reliable solution for meeting these evolving industrial requirements.

Comparison Table: Hastelloy B-2 Plate vs Alternatives

| Property | Hastelloy B-2 Plate (UNS N10665) | Hastelloy C-22 Plate (UNS N06022) | Stainless Steel 316L Plate |

|---|---|---|---|

| Base Material | Nickel-Molybdenum Alloy | Nickel-Chromium-Molybdenum Alloy | Iron-Nickel-Chromium |

| Resistance to Reducing Acids | Excellent | Very Good | Poor |

| Resistance to Oxidizers | Limited | Excellent versatile | Moderate |

| Hydrochloric Acid | Excellent at all concentrations | Good | Poor |

| High-Temperature Strength | Very Good | Excellent | Moderate |

| Weldability | Good with proper practices | Good | Excellent |

| Pitting/Crevice Resistance | Excellent in reducing conditions | Excellent | Limited |

| Applications | Chemical, petrochemical, pharma | Marine, chemical, petrochemical | Food, mild chemicals |

| Temperature Range | Up to ~815°C | Up to ~1000°C | Up to ~870°C |

| Cost Level | Higher | Higher | Lower |

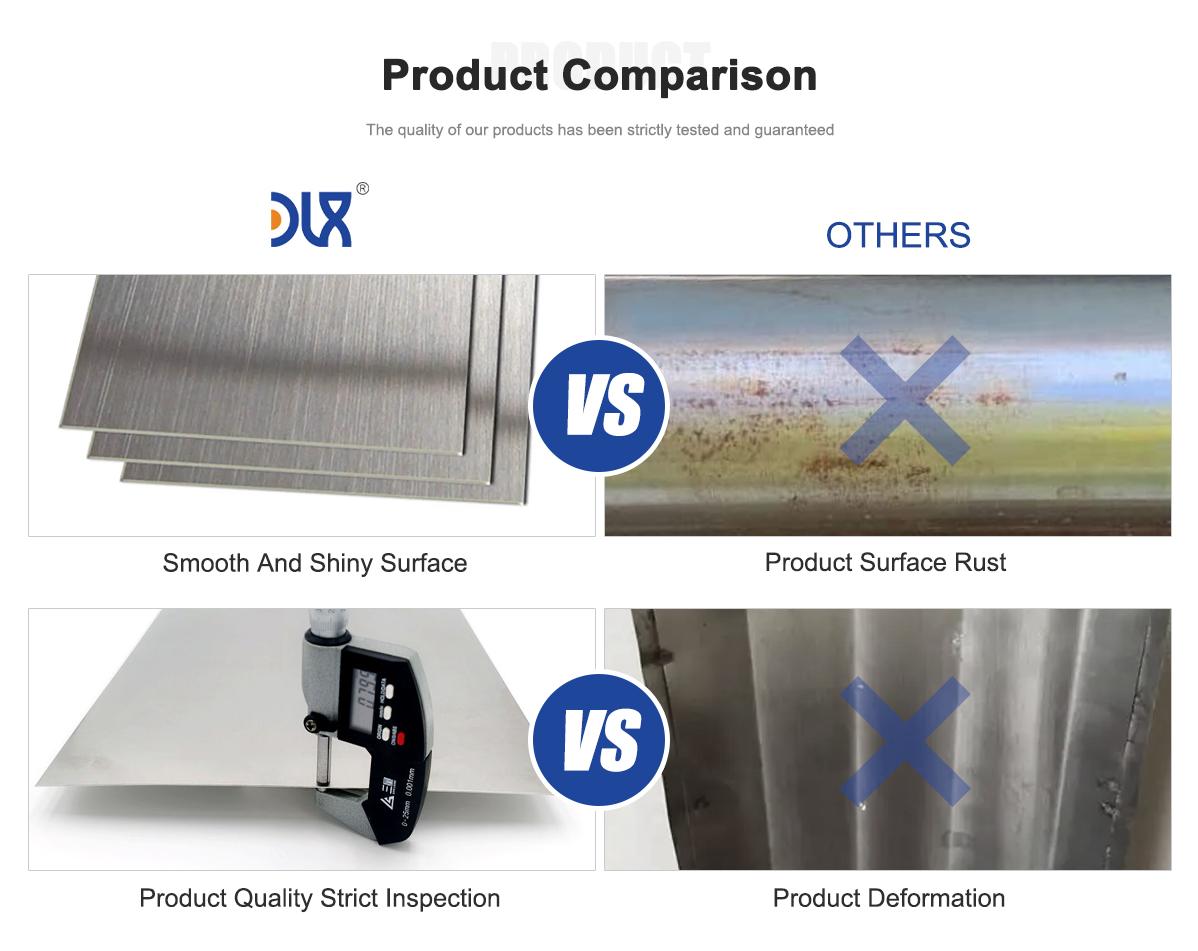

At DLX, we understand that choosing a supplier is about more than just purchasing a product. It’s about securing long-term reliability and support. Here’s what sets us apart in the market for Hastelloy B-2 Plates:

-

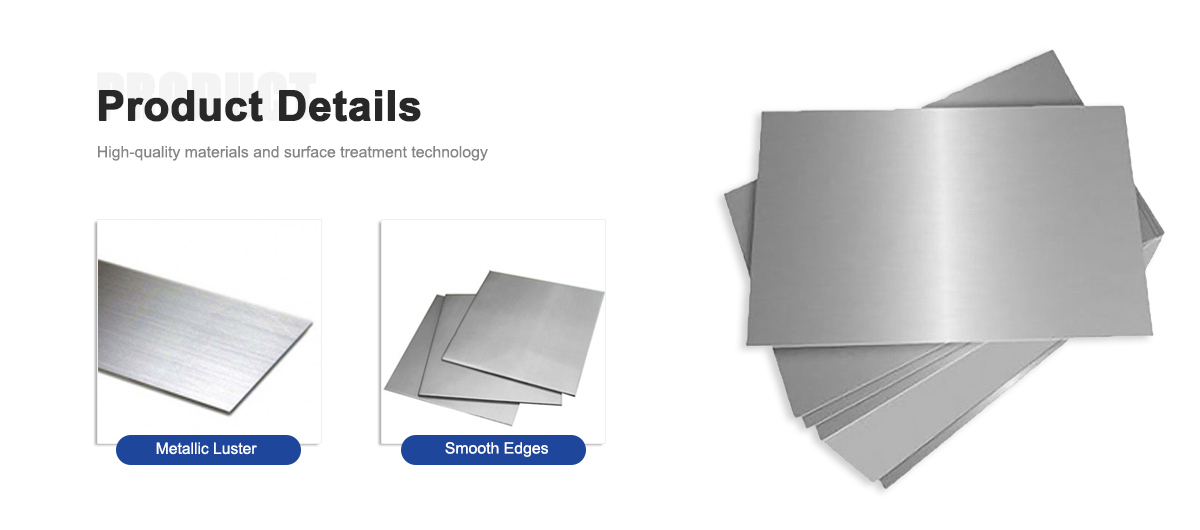

Compliance with International Standards: All plates are produced in accordance with ASTM B333 specifications, ensuring quality and consistency.

-

Tailored Solutions: We provide customized thicknesses, dimensions, and finishes based on specific client needs.

-

Strict Quality Control: Each batch is thoroughly tested for mechanical strength, corrosion resistance, and dimensional accuracy.

-

Fabrication Support: Our technical experts guide clients on welding, cutting, and forming practices.

-

Global Distribution Network: We serve customers worldwide with reliable logistics and on-time delivery.

-

Competitive Value: High-performance alloys supplied at competitive prices without compromising on quality.

This approach ensures that DLX is not just a supplier, but a long-term partner in helping clients succeed with their projects.

While stainless steel is widely used in industrial applications, it falls short when exposed to strong reducing acids like hydrochloric acid. Stainless steel 316L, for example, provides adequate performance in mild environments but fails rapidly in aggressive acid conditions. Hastelloy C-22, on the other hand, offers a balance between reducing and oxidizing environments, but Hastelloy B-2 remains unmatched in hydrochloric acid resistance.

DLX helps clients select the most appropriate material for their applications, balancing cost, performance, and long-term operational needs.

The global market for Hastelloy B-2 Plates is expanding as industries demand higher reliability and longer service life for their equipment. Some of the main drivers of growth include:

-

Expansion of chemical processing plants in Asia and North America.

-

Increasing investments in pharmaceutical production requiring clean, acid-resistant materials.

-

Rising importance of environmental compliance in pollution control and waste treatment.

-

Continued growth in petrochemicals and power generation infrastructure.

DLX is well-positioned to meet these demands, offering a combination of high-quality products and industry expertise.

Conclusion

Hastelloy B-2 Plate is a high-performance nickel-molybdenum alloy designed to withstand aggressive reducing environments, particularly hydrochloric acid. Its superior resistance to acid attack, excellent mechanical strength, and stability under stress make it indispensable in industries such as chemical processing, pharmaceuticals, petrochemicals, and pollution control.

At DLX, we supply ASTM-compliant Hastelloy B-2 Plates, offering tailored solutions, strict quality standards, and reliable delivery worldwide. By combining top-quality materials with expert support, we help our clients achieve greater durability, efficiency, and safety in their operations.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is Hastelloy B-2 Plate?

A1: It is a nickel-molybdenum alloy plate with excellent resistance to hydrochloric acid and other strong reducing environments.

Q2: What industries commonly use Hastelloy B-2 Plates?

A2: Chemical processing, petrochemicals, pharmaceuticals, power generation, and pollution control.

Q3: How does Hastelloy B-2 Plate perform in hydrochloric acid?

A3: It provides outstanding resistance at all concentrations and temperatures.

Q4: Is Hastelloy B-2 Plate resistant to oxidizing media?

A4: It performs best in reducing conditions and should be avoided in strongly oxidizing environments.

Q5: Can Hastelloy B-2 Plates be welded?

A5: Yes, with proper welding practices they maintain corrosion resistance and mechanical stability.

Q6: How does Hastelloy B-2 compare to stainless steels?

A6: It offers far superior acid resistance, especially in hydrochloric acid, where stainless steels typically fail.

Q7: What is the temperature range for Hastelloy B-2 Plates?

A7: They maintain reliable performance up to about 815°C in reducing conditions.

Q8: Why choose DLX for Hastelloy B-2 Plates?

A8: DLX provides ASTM-compliant products, tailored solutions, strict quality control, and reliable global supply.