Hastelloy C-4 Plate: Durable Nickel-Chromium-Molybdenum Alloy for High-Temperature Use

Industrial applications are constantly evolving, pushing materials to perform in harsher, hotter, and more chemically aggressive environments. In such demanding conditions, Hastelloy C-4 Plate emerges as one of the most reliable solutions. This nickel-chromium-molybdenum alloy is engineered to maintain excellent corrosion resistance and structural stability at elevated temperatures. DLX specializes in the production and supply of high-quality Hastelloy C-4 Plates, helping industries around the world achieve safer and more efficient operations.

For more details, pls directly contact us.

Hastelloy C-4 (UNS N06455) is part of the corrosion-resistant nickel alloy family, specifically designed to excel in high-temperature oxidizing environments. Its chemical composition—primarily nickel, with carefully balanced additions of chromium and molybdenum—delivers outstanding resistance against strong oxidizers and localized corrosion phenomena.

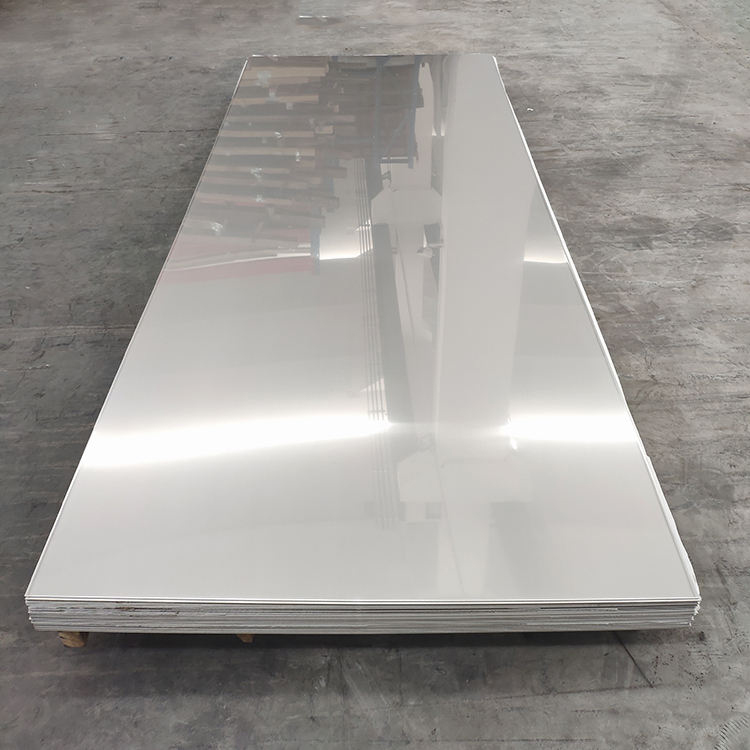

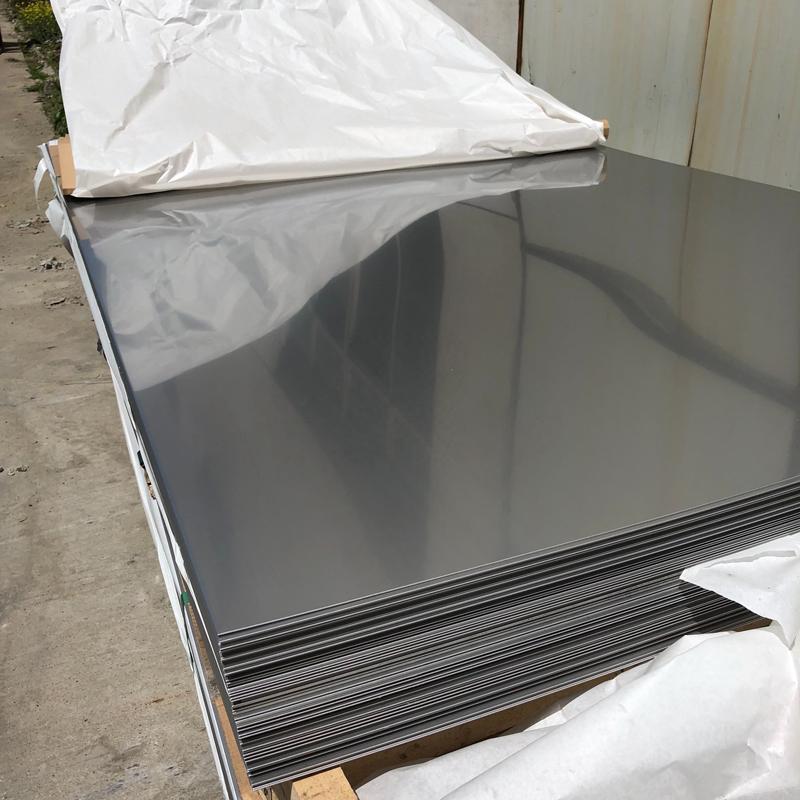

Plates produced from Hastelloy C-4 are widely used in fabricating tanks, pressure vessels, piping systems, heat exchangers, and structural parts exposed to aggressive chemical and thermal conditions. The alloy’s combination of formability, weldability, and strength ensures that it can be processed into complex components without compromising performance. At DLX, our Hastelloy C-4 Plates undergo rigorous quality inspections and are manufactured to meet ASTM standards, providing clients with consistent and dependable materials.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

The versatility of Hastelloy C-4 Plates makes them essential in multiple industries:

-

Chemical Processing: Ideal for equipment handling oxidizing acids, chlorine compounds, and contaminated solutions.

-

Aerospace Industry: High-performance alloys are vital in parts exposed to both extreme temperatures and corrosive environments.

-

Pharmaceuticals: Provides a sterile, corrosion-resistant surface for equipment in aggressive cleaning and production environments.

-

Pollution Control: Flue gas scrubbers, stack liners, and waste treatment systems require reliable resistance against mixed corrosives.

-

Petrochemicals: Effective for processing environments where both heat and aggressive catalysts are present.

By selecting DLX’s Hastelloy C-4 Plates, customers gain confidence in material integrity for long-term use in the harshest applications.

Industry Analysis

Industries worldwide are facing mounting challenges. Global expansion in energy, chemicals, and environmental protection drives demand for alloys capable of enduring extreme conditions. Key trends influencing demand for Hastelloy C-4 include:

-

Stricter Environmental Standards: Pollution control systems are expected to operate under harsher conditions for longer periods, requiring materials with exceptional stability.

-

Chemical Processing Growth: Facilities are increasingly handling aggressive substances that demand advanced alloys.

-

Aerospace Advancements: With new aerospace technologies and materials exposed to high-temperature corrosive gases, alloys like Hastelloy C-4 are crucial.

-

Pharmaceutical Expansion: Demand for high-purity and reliable materials continues to grow.

-

Global Energy Projects: Petrochemical and refinery investments highlight the need for alloys that withstand both chemical and thermal stress.

Hastelloy C-4 Plates fit perfectly into this evolving industrial environment, offering unmatched resistance and stability.

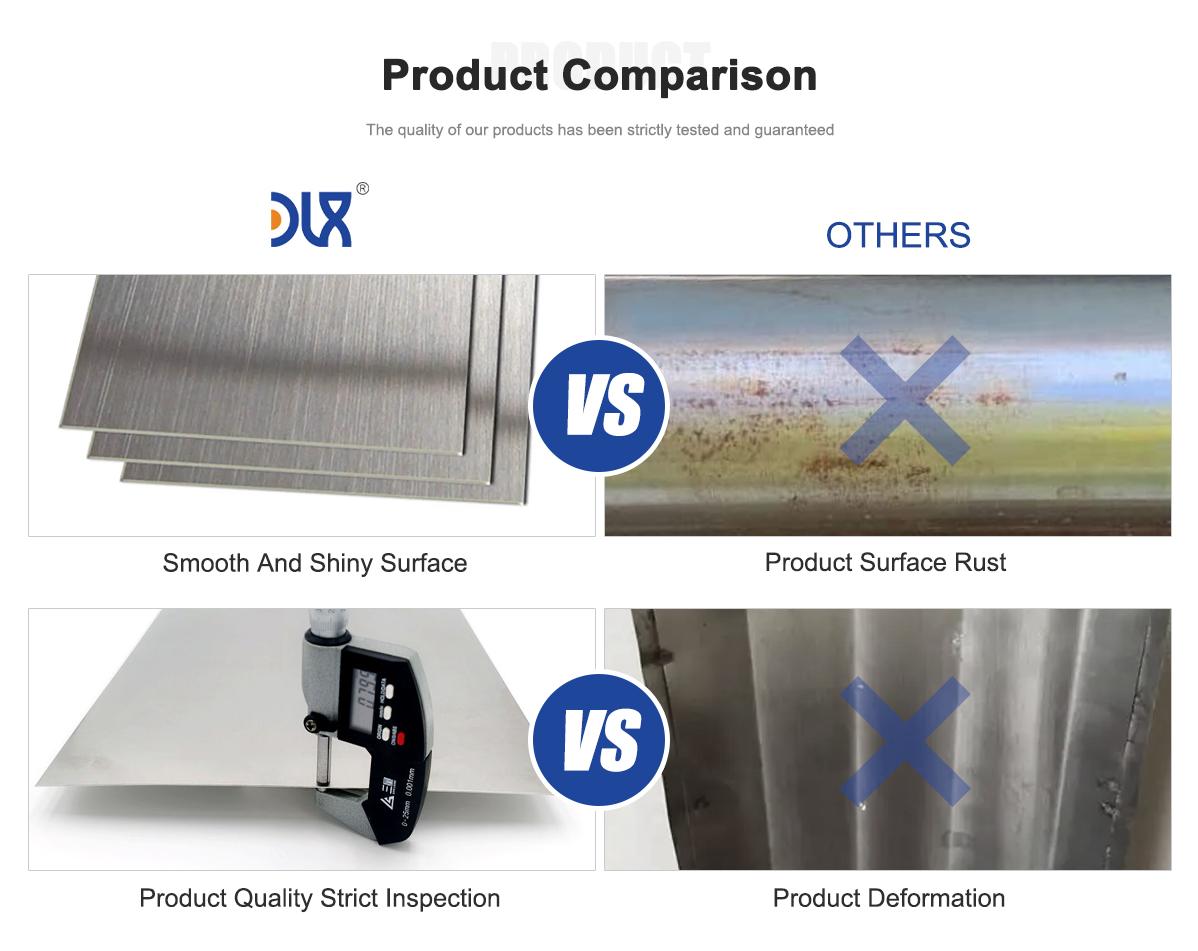

Choosing the right supplier is as critical as selecting the right material. DLX provides more than alloy plates—we deliver a partnership built on reliability, expertise, and customer satisfaction.

-

ASTM-Compliant Production: Every Hastelloy C-4 Plate adheres to ASTM B575 standards.

-

Custom Solutions: Thickness, dimensions, and finishes tailored to customer requirements.

-

Quality Control: Comprehensive testing ensures mechanical strength and corrosion resistance.

-

Technical Expertise: Our team supports customers with welding, machining, and fabrication guidance.

-

Global Supply Chain: Efficient logistics guarantee on-time delivery worldwide.

-

Commitment to Value: We offer premium alloys with competitive pricing to maximize customer returns.

This combination of high-quality materials and strong customer support makes DLX a trusted partner across industries.

Comparison Table: Hastelloy C-4 Plate vs Other Alloys

| Property | Hastelloy C-4 Plate (UNS N06455) | Hastelloy C-22 Plate (UNS N06022) | Stainless Steel 316L Plate |

|---|---|---|---|

| Base Material | Nickel-Chromium-Molybdenum Alloy | Nickel-Chromium-Molybdenum Alloy | Iron-Nickel-Chromium |

| Oxidizing Resistance | Excellent (High Temp Stability) | Excellent (Versatile) | Moderate |

| Reducing Resistance | Very Good | Very Good | Limited |

| High-Temperature Strength | Excellent | Excellent | Moderate |

| Chloride Resistance | Excellent | Excellent | Moderate |

| Weldability | Good | Good | Excellent |

| Pitting/Crevice Resistance | Excellent | Excellent | Limited |

| Applications | Chemical, aerospace, pollution control, pharmaceuticals | Chemical, petrochemical, marine | Food, mild chemicals |

| Temperature Range | Up to ~1000°C | Up to ~1000°C | Up to ~870°C |

| Cost Level | Higher | Higher | Lower |

While stainless steel and other nickel alloys remain common in industrial settings, they often cannot match the specific advantages of Hastelloy C-4. Stainless steel 316L, for example, is a cost-effective choice for mild environments but fails under high temperatures or strong oxidizers. Hastelloy C-22 provides versatile resistance in mixed environments, but C-4 stands out for its exceptional stability at elevated temperatures in oxidizing atmospheres.

DLX guides customers in choosing the best alloy for their needs, ensuring that they receive not only high-performance materials but also practical cost-effective solutions.

The demand for Hastelloy C-4 Plates is projected to expand significantly as industries continue to prioritize safety, reliability, and long-term performance. Growth in the following areas will drive demand:

-

Expansion of chemical and petrochemical plants in Asia and the Middle East.

-

Increased aerospace projects requiring high-performance alloys.

-

Rising demand for pollution control equipment in response to stricter environmental regulations.

-

Continued pharmaceutical growth, particularly in sterile, high-purity production facilities.

DLX is strategically positioned to meet this demand with reliable products, strong customer support, and efficient logistics.

Hastelloy C-4 Plate is a durable, nickel-chromium-molybdenum alloy that delivers superior corrosion resistance and stability in high-temperature applications. It is an essential material for chemical processing, aerospace, petrochemical, pharmaceutical, and environmental systems.

At DLX, we manufacture and supply ASTM-compliant Hastelloy C-4 Plates, offering quality assurance, customization, and dependable service. With a focus on long-term partnerships, we provide solutions that enable our customers to succeed in the world’s harshest environments.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is Hastelloy C-4 Plate?

A1: It is a nickel-chromium-molybdenum alloy plate designed for excellent resistance to strong oxidizers, stress corrosion cracking, and high-temperature environments.

Q2: What industries typically use Hastelloy C-4 Plates?

A2: Chemical processing, aerospace, pharmaceutical, petrochemical, and pollution control industries.

Q3: What is the key advantage of Hastelloy C-4 compared to conventional stainless steels?

A3: It maintains exceptional corrosion resistance and stability at high temperatures, where stainless steels may fail.

Q4: Is Hastelloy C-4 Plate resistant to chloride-induced corrosion?

A4: Yes, it offers superior resistance to localized corrosion such as pitting and crevice attack in chloride environments.

Q5: Can Hastelloy C-4 Plates be fabricated and welded easily?

A5: Yes, they can be welded and formed without significant risk of grain boundary precipitation.

Q6: What temperature range can Hastelloy C-4 Plates handle?

A6: They perform effectively up to around 1000°C in aggressive service environments.

Q7: How does Hastelloy C-4 compare to Hastelloy C-22?

A7: C-4 is especially stable in high-temperature oxidizing conditions, while C-22 is more versatile in mixed oxidizing and reducing environments.

Q8: Why should customers choose DLX for Hastelloy C-4 Plates?

A8: DLX provides ASTM-compliant materials, precision manufacturing, technical expertise, and reliable global supply.