UNS N10665 Hastelloy B-2 Sheet for Chemical and Petrochemical Processing

Selecting the right alloy sheet is critical when equipment is exposed to aggressive chemical environments. Among the high-performance materials available today, UNS N10665 Hastelloy B-2 Sheet is recognized as one of the most reliable solutions for reducing acid resistance. At DLX, we specialize in supplying this alloy in sheet form, engineered to meet the most demanding standards in chemical and petrochemical applications.

For more details, pls directly contact us.

Hastelloy B-2 Sheet (UNS N10665) is a nickel-molybdenum alloy designed to handle highly aggressive reducing media. It provides outstanding resistance to hydrochloric acid across all concentrations and temperatures. Unlike many alloys, it resists localized corrosion such as pitting and crevice attack under reducing conditions, making it a preferred material for critical process equipment.

The alloy’s improved thermal stability minimizes the risk of carbide precipitation during welding, ensuring that its corrosion resistance is not compromised. Available in various thicknesses and dimensions, Hastelloy B-2 Sheets from DLX can be tailored to fit diverse industry requirements.

Specification

item | HC-276 | C-22 | C-4 | B2 | B3 | N |

C | ≤0.01 | ≤0.015 | ≤0.015 | ≤0.02 | ≤0.01 | 0.04-0.08 |

Mn | ≤1 | ≤0.5 | ≤1 | ≤1 | ≤3 | ≤1 |

Fe | 4-7 | 2-6 | ≤3 | ≤2 | ≤1.5 | ≤5 |

P | ≤0.04 | ≤0.02 | ≤0.04 | ≤0.04 | -- | ≤0.015 |

S | ≤0.03 | ≤0.02 | ≤0.03 | ≤0.03 | -- | ≤0.02 |

Si | ≤0.08 | ≤0.08 | ≤0.08 | ≤0.1 | ≤0.1 | ≤1 |

Ni | rest | rest | rest | rest | ≤65 | rest |

Co | ≤2.5 | ≤2.5 | ≤2 | ≤1 | ≤3 | ≤0.2 |

Ti+Cu | -- | -- | ≤0.7 | -- | ≤0.4 | ≤0.35 |

Al+Ti | -- | -- | -- | -- | ≤0.5 | ≤0.5 |

Cr | 14.5-16.5 | 20-22.5 | 14-18 | ≤1 | ≤1.5 | 6-8 |

Mo | 15-17 | 12.5-14.5 | 14-17 | 26-30 | ≤28.5 | 15-18 |

B | -- | -- | -- | -- | -- | ≤0.01 |

W | 3-4.5 | 2.5-3.5 | -- | -- | ≤3 | ≤0.5 |

V | ≤0.35 | ≤0.35 | -- | 0.2-0.4 | -- | ≤0.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

For more details, pls directly contact us.

Hastelloy B-2 Sheets play a vital role in industries where failure is not an option. Some of the major application areas include:

Chemical Processing: Storage tanks, heat exchangers, and reactors handling hydrochloric acid.

Petrochemical Plants: Equipment in contact with reducing agents where traditional alloys would fail.

Pharmaceutical Industry: Corrosion-resistant surfaces for production equipment requiring cleanliness and durability.

Pollution Control: Acid-resistant linings and scrubbers for treating aggressive industrial waste streams.

Power Generation: Components exposed to acid condensates in flue gas scrubbers and related systems.

By selecting DLX’s Hastelloy B-2 Sheets, customers benefit from longer service life, lower maintenance costs, and improved operational safety.

The global demand for advanced corrosion-resistant materials is on the rise. Several factors are driving this trend:

Expansion of Chemical Industry: Increased production of hydrochloric acid and related compounds requires durable materials.

Petrochemical Growth: New refineries and processing units in Asia and the Middle East are increasing the demand for robust alloys.

Stricter Environmental Regulations: Governments worldwide are enforcing stricter rules for handling hazardous chemicals, necessitating advanced materials like Hastelloy B-2.

Pharmaceutical Advancements: Higher purity standards and safety requirements demand alloys with proven acid resistance.

Global Infrastructure Development: Corrosion-resistant alloys are being chosen to extend equipment life and minimize downtime.

These factors indicate a steady growth trajectory for Hastelloy B-2 Sheets in the coming years.

Comparison Table: Hastelloy B-2 Sheet vs Alternatives

| Property | Hastelloy B-2 Sheet (UNS N10665) | Hastelloy C-22 Sheet (UNS N06022) | Stainless Steel 316L Sheet |

|---|---|---|---|

| Base Material | Nickel-Molybdenum Alloy | Nickel-Chromium-Molybdenum Alloy | Iron-Nickel-Chromium |

| Resistance to Reducing Acids | Excellent | Very Good | Poor |

| Resistance to Oxidizers | Limited | Excellent versatile | Moderate |

| Hydrochloric Acid | Excellent at all concentrations | Good | Poor |

| High-Temperature Strength | Very Good | Excellent | Moderate |

| Weldability | Good with proper techniques | Good | Excellent |

| Pitting/Crevice Resistance | Excellent in reducing conditions | Excellent | Limited |

| Applications | Chemical, petrochemical, pharma | Marine, chemical, petrochemical | Food, mild chemicals |

| Temperature Range | Up to ~815°C | Up to ~1000°C | Up to ~870°C |

| Cost Level | Higher | Higher | Lower |

DLX stands out as a trusted supplier of UNS N10665 Hastelloy B-2 Sheets for several reasons:

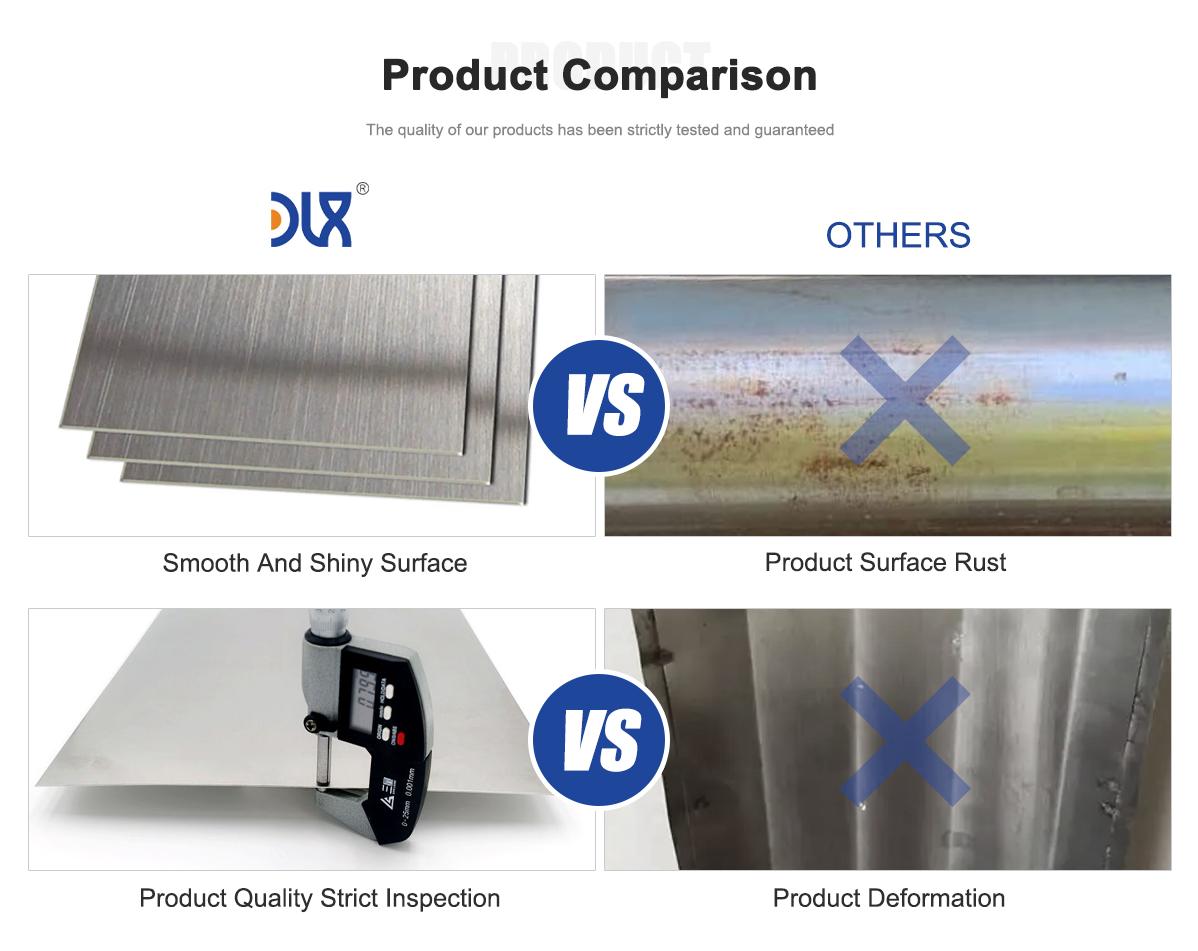

Quality Compliance: All products meet ASTM B333 specifications, ensuring reliability and consistency.

Customization Options: Thickness, width, and finish can be tailored according to client requirements.

Stringent Quality Control: Every batch undergoes rigorous mechanical and corrosion resistance testing.

Technical Support: Our team provides fabrication and welding guidance to maximize performance.

Global Supply Chain: With a robust distribution network, we ensure on-time delivery worldwide.

Value Proposition: Clients receive top-grade alloys at competitive pricing with no compromise on quality.

This combination of expertise, reliability, and customer focus has positioned DLX as a long-term partner to industries requiring advanced nickel alloys.

Compared with stainless steels, Hastelloy B-2 delivers superior acid resistance, especially in hydrochloric acid. Stainless steels are cost-effective for mild environments but fail quickly in strong reducing acids. Hastelloy C-22, while excellent in oxidizing conditions, is not as effective as Hastelloy B-2 in pure reducing media.

This distinction makes Hastelloy B-2 the alloy of choice for specific environments, and DLX helps clients evaluate these material trade-offs to optimize performance.

The market for Hastelloy B-2 Sheets is expected to expand steadily as industries prioritize performance and safety over short-term cost savings. Key regions of growth include:

Asia-Pacific: Rapid industrialization and refinery expansion.

North America: Strong presence of chemical and pharmaceutical industries.

Middle East: Investments in petrochemical infrastructure.

As industries evolve, DLX continues to adapt, ensuring that our products meet both current and future market needs.

Conclusion

UNS N10665 Hastelloy B-2 Sheet is an essential material for industries that operate in aggressive reducing environments. With its superior resistance to hydrochloric acid, excellent thermal stability, and reliable mechanical properties, it delivers unmatched durability for critical process applications.

At DLX, we take pride in supplying Hastelloy B-2 Sheets that meet international standards, backed by strong technical expertise and a customer-first approach. By partnering with us, industries can achieve greater operational efficiency, reduced downtime, and long-term success in demanding environments.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is UNS N10665 Hastelloy B-2 Sheet?

A1: It is a nickel-molybdenum alloy sheet designed for excellent resistance to hydrochloric acid and other strong reducing environments.

Q2: What industries use Hastelloy B-2 Sheets?

A2: They are widely used in chemical processing, petrochemicals, pharmaceuticals, pollution control, and energy systems.

Q3: How does Hastelloy B-2 perform in hydrochloric acid?

A3: It provides outstanding resistance at all concentrations and temperatures.

Q4: Is Hastelloy B-2 resistant to oxidizing environments?

A4: It is not suitable for strong oxidizing conditions but excels in reducing acids.

Q5: What is the maximum temperature for Hastelloy B-2 Sheets?

A5: They perform reliably up to around 815°C in reducing environments.

Q6: Can Hastelloy B-2 Sheets be fabricated?

A6: Yes, they can be welded and formed with proper techniques, retaining corrosion resistance.

Q7: How does Hastelloy B-2 compare with stainless steels?

A7: It offers superior resistance to strong acids, particularly hydrochloric acid, where stainless steels quickly fail.

Q8: Why choose DLX for Hastelloy B-2 Sheets?

A8: DLX provides ASTM-compliant materials, global supply capability, strict quality control, and customized solutions.