Age-Hardenable Monel K500 Wire: Durable Alloy for Aerospace and Chemical Processing

Our Age-Hardenable Monel K500 wire is a rock-solid choice for industries like aerospace and chemical processing, where performance under pressure is everything. This nickel-copper alloy wire isn’t just durable—it’s engineered to handle the toughest environments with ease, from high-altitude aircraft systems to corrosive chemical plants. With its unbeatable strength, corrosion resistance, and versatility, our Monel K500 wire is designed to keep your projects running smoothly, no matter how extreme the conditions. We’re proud to offer a product that stands up to the demands of cutting-edge engineering and delivers results you can count on.

For more details, pls directly contact us.

Let’s get into what makes our Monel K500 wire so special. It’s made from a nickel-copper alloy, with about 65% nickel and 30% copper, plus a smart addition of aluminum and titanium. These extra elements are the secret sauce, giving the wire its high strength through age-hardening while keeping the corrosion resistance Monel alloys are known for. We’re talking serious muscle here—tensile strength up to 160 ksi and yield strength reaching 110 ksi. That’s the kind of toughness that makes it perfect for high-stress applications. It’s also non-magnetic, which is a big deal for aerospace systems where interference can’t be tolerated. From freezing -200°F to a blistering 1200°F, our Monel K500 wire stays strong, making it ideal for the wild temperature swings in jet engines or chemical reactors.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

Corrosion resistance is where our Monel K500 wire really flexes its muscles. In chemical processing, it stands up to aggressive acids like sulfuric and hydrofluoric, as well as alkalis and corrosive gases, without breaking a sweat. In aerospace, it shrugs off de-icing fluids, saltwater exposure, and atmospheric corrosion, ensuring long-term reliability. Tests show our wire lasting over 10,000 hours in acidic environments with minimal wear, which means less maintenance and fewer replacements for you. It resists pitting, crevice corrosion, and stress corrosion cracking, making it a top pick for valve springs, heat exchanger wires, and control cables. If you’re searching for age-hardenable Monel K500 wire for aerospace or chemical processing, this is a material that delivers durability and peace of mind in the harshest conditions.

Looking at the broader industry landscape, the demand for high-performance alloys like our Monel K500 wire is on the rise. The aerospace sector is booming, with global market growth projected at 5-7% CAGR through 2030, driven by innovations like electric aircraft, drones, and hypersonic vehicles. These advancements call for materials that can handle extreme stresses while staying lightweight—exactly what our wire offers. In chemical processing, automation and stricter environmental regulations are pushing companies to choose durable, low-maintenance materials to reduce downtime and emissions. Monel K500 fits perfectly, supporting greener operations with its long lifespan. We’re also seeing growth in emerging fields like hydrogen production and carbon capture, where corrosion-resistant alloys are critical. Regions like North America, Europe, and Asia-Pacific are leading the charge, with heavy investments in aerospace manufacturing and chemical plant expansions fueling demand for reliable materials.

When it comes to applications, our Monel K500 wire is a versatile workhorse. In aerospace, it’s a go-to for control cables, fasteners, and springs in aircraft systems. Its high strength-to-weight ratio makes it ideal for components that need to endure vibration and thermal cycling, like those in jet engines or landing gear. In chemical processing, it’s used in heat exchanger wires, pump shafts, and valve components, where its resistance to corrosive media keeps operations running smoothly. We’ve also supplied it for marine applications, like offshore platform cables, and even for emerging tech like geothermal energy systems. The beauty of our wire is its customizability—we can fine-tune diameters, tempers, and finishes to meet your exact specs, whether you need ultra-fine wires for precision sensors or heavy-gauge options for structural support.

What sets our company apart is our commitment to quality and innovation. We produce Monel K500 wire to ASTM B865 standards, with rigorous testing from raw material sourcing to final inspection. Our advanced cold-drawing and age-hardening processes ensure uniform strength and flawless surface quality, minimizing defects that could lead to failures. Compared to standard wires, our Monel K500 offers superior fatigue resistance and tighter tolerances, thanks to our proprietary heat treatment methods. We’re also focused on sustainability, using recycled nickel to reduce our environmental footprint without compromising performance. Our customers love our flexibility—rapid prototyping, custom spooling, and just-in-time delivery keep your projects on track. Plus, our team of metallurgists is always ready to provide technical support, whether you’re designing a new aerospace component or optimizing a chemical process.

Comparison Parameters Table

| Parameter | Monel K500 Wire | Monel 400 Wire | Stainless Steel 316 Wire |

|---|---|---|---|

| Composition | 65% Ni, 30% Cu, 2-3% Al, 0.5% Ti | 63% Ni, 28-34% Cu | 16-18% Cr, 10-14% Ni, 2-3% Mo |

| Density (g/cm³) | 8.44 | 8.8 | 8.0 |

| Tensile Strength (ksi) | 140-160 | 70-85 | 75-90 |

| Yield Strength (ksi) | 90-110 | 25-50 | 30-40 |

| Corrosion Resistance | Excellent in acids, alkalis, seawater; resists pitting and cracking | Excellent in seawater, acids; slightly less in extreme conditions | Good in chlorides; prone to pitting in seawater |

| Temperature Range (°F) | -200 to 1200 | -200 to 1000 | -320 to 1500 |

| Magnetic Properties | Non-magnetic | Low magnetism | Slightly magnetic |

| Cost Factor | Higher due to alloying | Moderate | Lower |

| Typical Applications | Aerospace cables, chemical springs | Marine, chemical processing | Medical, food processing |

The advantages of our Monel K500 wire are clear. Its corrosion resistance in acids and seawater is unmatched, often outlasting stainless steel by a factor of two in harsh environments. This means lower maintenance costs and less downtime, which is critical for aerospace and chemical operations. The age-hardening process gives it a strength edge over Monel 400, making it ideal for high-stress applications without adding bulk. We’ve helped clients cut replacement costs by 25% by switching to our wire for critical components like valve springs. With industry trends leaning toward greener technologies and more extreme operating conditions, our wire is ready to support the future, from hydrogen infrastructure to advanced aerospace designs. It’s a material that’s as reliable as it is forward-thinking.

For more details, pls directly contact us.

About Us:

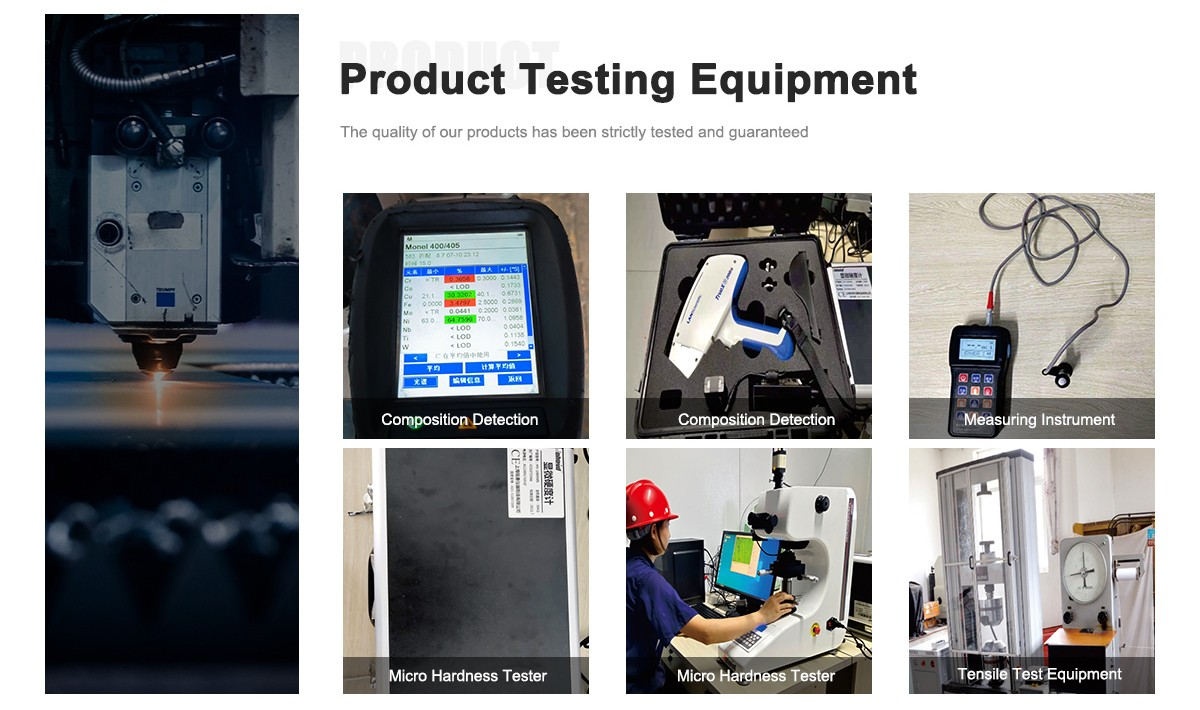

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Age-Hardenable Monel K500 wire made of?

It’s a nickel-copper alloy with roughly 65% nickel, 30% copper, and small amounts of aluminum and titanium for enhanced strength.What are the key features of Monel K500 wire?

It offers high tensile strength (up to 160 ksi), excellent corrosion resistance, non-magnetic properties, and performance from -200°F to 1200°F.What aerospace applications use Monel K500 wire?

It’s used in control cables, fasteners, and springs for aircraft, where its strength and corrosion resistance handle high-stress conditions.How does Monel K500 wire perform in chemical processing?

It resists acids, alkalis, and corrosive gases, making it ideal for valve springs, heat exchanger wires, and chemical plant piping.What industry trends are driving demand for Monel K500 wire?

Growth in aerospace innovation, chemical process automation, and demand for durable, low-maintenance alloys are boosting its use.Is Monel K500 wire suitable for extreme environments?

Yes, its high yield strength (up to 110 ksi) and resistance to stress corrosion cracking make it perfect for harsh aerospace and chemical settings.