UNS N05500 Monel K500 Wire: Corrosion-Resistant Solution for Oil and Gas Industry

Our UNS N05500 Monel K500 wire is a top-tier solution built to take on the brutal conditions of the oil and gas industry. This high-strength nickel-copper alloy wire isn’t just tough—it’s designed to thrive where corrosion, pressure, and extreme environments could bring lesser materials to their knees. From deepwater rigs to sour gas wells, our Monel K500 wire delivers unmatched reliability, keeping your operations running smoothly and efficiently. We’ve poured our expertise into crafting a product that’s as versatile as it is durable, making it a go-to choice for engineers tackling the toughest challenges in oil and gas exploration.

For more details, pls directly contact us.

So, what’s the deal with our Monel K500 wire? It starts with its composition: about 65% nickel, 30% copper, and a strategic dose of aluminum and titanium. These additions make it a standout, giving it a serious strength boost through age-hardening while keeping the corrosion resistance that the Monel family is famous for. We’re talking tensile strength up to 160 ksi and yield strength hitting 110 ksi—numbers that put it head and shoulders above many alternatives. It’s also non-magnetic, which is a big win for sensitive instrumentation in oil and gas setups. Whether it’s freezing cold at -200°F or blistering hot up to 1200°F, our Monel K500 wire holds up, making it perfect for the wild temperature swings you’ll find in drilling operations or subsea systems.

Parameter:

Item | Ni | Cu | Fe | Mn | C | Si | S |

≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 |

Item | Ni | Cu | Al | Ti | Fe | Mn | S | C | Si |

Monel K500 | ≥63 | 27-33 | 2.3-3.15 | 0.35-0.85 | ≤2 | ≤1.5 | ≤0.01 | ≤0.25 | ≤0.5 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB |

Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 |

Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation |

Monel K500 | 8.05 g/cm3 | 1288-1343℃ | 1100 | 790 | 20% |

Monel 400 | Bar / Rod | Forging | Pipe | Sheet / Strip | Welding Wire |

Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 |

Monel K500 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire |

Standard | ASTM B864 | AMS4676 | ASTM B865 | ASTM B564 | ErNiCu-7 |

For more details, pls directly contact us.

Corrosion resistance is the name of the game in oil and gas, and our Monel K500 wire is a champion in this arena. It laughs off harsh conditions like hydrogen sulfide, carbon dioxide, and seawater that would chew through other materials. In sour gas environments, it resists stress corrosion cracking and pitting, which means fewer failures and less downtime. Lab tests show our wire lasting over 15,000 hours in aggressive saltwater conditions with barely a scratch, making it a solid pick for wirelines, valve springs, and downhole tools. It’s also a star in chemical processing, handling acids like sulfuric and hydrofluoric without breaking down. If you’re searching for UNS N05500 Monel K500 wire for oil and gas applications, you’re looking at a material that cuts maintenance costs and boosts equipment lifespan, no matter how tough the job.

Let’s talk industry trends. The oil and gas sector is in a transformative phase, and materials like our Monel K500 wire are right at the heart of it. Deepwater drilling is on the rise, with global offshore production expected to grow at a 5% CAGR through 2030. Shale gas and unconventional reserves are pushing the limits of equipment durability, and our wire is built to meet those demands. Environmental regulations are getting stricter, driving companies to invest in low-maintenance, long-lasting materials to avoid leaks and spills. Monel K500 fits the bill, offering reliability that supports greener operations. We’re also seeing a boom in digital technologies like predictive maintenance, where durable materials like our wire integrate seamlessly with smart sensors to optimize performance. Regions like the Middle East, North America, and West Africa are fueling demand, with major projects leaning on high-strength alloys to handle extreme conditions.

When it comes to applications, our Monel K500 wire is a Swiss Army knife for oil and gas. It’s a staple in wirelines for logging and intervention, where its high strength and corrosion resistance ensure reliable performance in deep wells. You’ll find it in valve springs and pump components, standing up to the high pressures and sour gases common in offshore rigs. It’s also used in subsea control lines and umbilical cables, where its non-magnetic properties prevent interference with instrumentation. Beyond oil and gas, we’ve supplied it for marine applications like anchor cables and for chemical plants handling corrosive media. Emerging fields like geothermal energy and carbon capture systems are tapping into its durability too. We can tailor the wire to your exact needs—fine diameters for precision work or heavier gauges for structural roles, all with custom tempers and finishes to match your specs.

What makes our company the best choice for Monel K500 wire? It’s all about quality, innovation, and service. We manufacture to ASTM B865 standards, with every batch undergoing strict testing from alloy mixing to final inspection. Our advanced cold-drawing and age-hardening processes deliver wire with superior uniformity and fatigue resistance, reducing the risk of failures in critical applications. Unlike standard options, our Monel K500 wire offers tighter tolerances and enhanced surface quality, thanks to our proprietary techniques. We’re also big on sustainability, using recycled nickel to cut our environmental impact without compromising strength. Our customers rave about our flexibility—whether it’s rapid prototyping, custom spooling, or just-in-time delivery, we’ve got you covered. Our team of metallurgists is always on hand to provide technical support, helping you design solutions for complex oil and gas challenges.

Comparison Parameters Table

| Parameter | UNS N05500 Monel K500 Wire | Monel 400 Wire | Stainless Steel 316L Wire |

|---|---|---|---|

| Composition | 65% Ni, 30% Cu, 2-3% Al, 0.5% Ti | 63% Ni, 28-34% Cu | 16-18% Cr, 10-14% Ni, 2-3% Mo |

| Density (g/cm³) | 8.44 | 8.8 | 8.0 |

| Tensile Strength (ksi) | 140-160 | 70-85 | 70-85 |

| Yield Strength (ksi) | 90-110 | 25-50 | 25-40 |

| Corrosion Resistance | Superior in sour gas, seawater, acids; resists pitting and cracking | Excellent in seawater, acids; slightly less in sour gas | Moderate; prone to pitting in chlorides |

| Temperature Range (°F) | -200 to 1200 | -200 to 1000 | -320 to 1400 |

| Magnetic Properties | Non-magnetic | Low magnetism | Slightly magnetic |

| Cost Factor | Higher due to alloying | Moderate | Lower |

| Typical Applications | Oil and gas wirelines, springs, marine | Chemical processing, marine | Medical, general industrial |

The advantages of our Monel K500 wire are hard to beat. Its corrosion resistance in sour gas and seawater environments is top-notch, often outlasting stainless steel by a factor of three in harsh tests. This means fewer replacements and lower downtime, which is a big deal for offshore operations where every minute costs money. The added aluminum and titanium give it a strength edge over Monel 400, making it ideal for high-stress applications without adding weight. We’ve helped clients slash maintenance costs by 20% by switching to our wire for downhole tools. With trends leaning toward sustainable energy and harsher exploration environments, our wire is ready to support the industry’s future, from hydrogen production to deep-sea carbon storage. It’s a material that’s as forward-thinking as it is reliable.

For more details, pls directly contact us.

About Us:

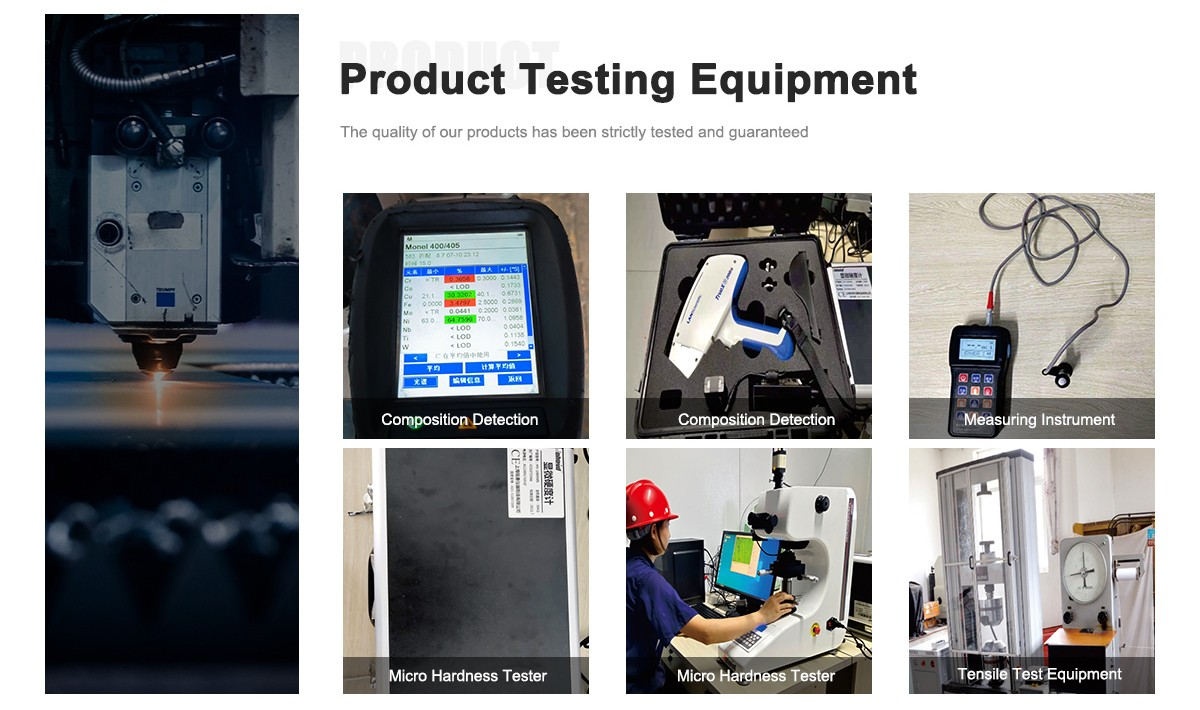

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is UNS N05500 Monel K500 wire composed of?

It’s a nickel-copper alloy with about 65% nickel, 30% copper, plus aluminum and titanium for added strength and hardness.What are the main properties of Monel K500 wire?

It offers high tensile strength (up to 160 ksi), excellent corrosion resistance, non-magnetic properties, and reliability from -200°F to 1200°F.What oil and gas applications use Monel K500 wire?

It’s used in downhole tools, valve springs, and wirelines for its durability in high-pressure, corrosive environments like sour gas wells.How does Monel K500 wire handle corrosive oil and gas conditions?

It resists pitting, stress corrosion cracking, and hydrogen sulfide attack, ensuring long-term performance in harsh drilling environments.What industry trends are increasing demand for Monel K500 wire?

Growth in deepwater drilling, shale gas exploration, and demand for low-maintenance materials are driving its adoption.Is Monel K500 wire suitable for high-stress oil and gas applications?

Yes, its high yield strength (up to 110 ksi) and fatigue resistance make it ideal for critical components under extreme pressure.How is Monel K500 wire customized for oil and gas needs?

It can be cold-drawn, age-hardened, or annealed to meet specific diameters, strengths, and tolerances for specialized applications.How does Monel K500 wire compare to Monel 400 in oil and gas?

Monel K500 offers higher strength and hardness due to aluminum and titanium additions, while maintaining similar corrosion resistance.