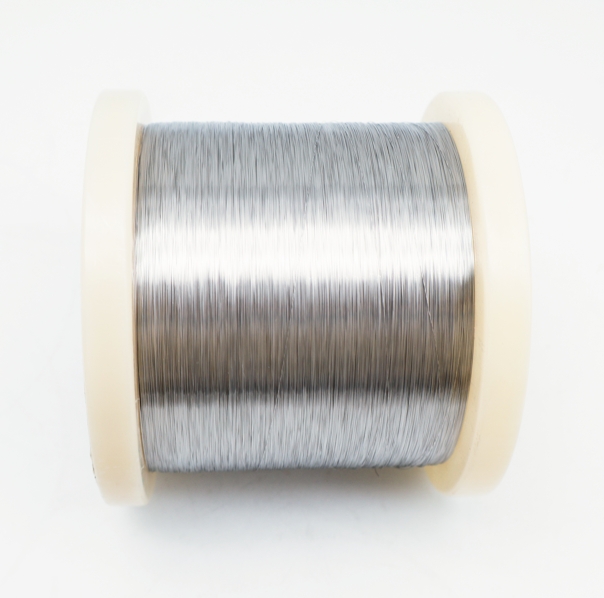

Durable Monel 400 Spring Wire for Aerospace Components

Our Durable Monel 400 Spring Wire for Aerospace Components is built to meet the high demands of the aerospace industry. This wire is tough, corrosion-resistant, and ready to perform in the harshest conditions, from extreme temperatures to corrosive environments. Let’s break down what makes our Monel 400 spring wire a top pick for aerospace applications, explore its uses, and dive into the trends shaping the industry.

For more details, pls directly contact us.

Our Monel 400 Spring Wire is crafted from a nickel-copper alloy, blending about 67% nickel with 23% copper, plus traces of iron and manganese. This combination delivers exceptional strength, corrosion resistance, and durability, making it a perfect fit for aerospace components. Whether it’s springs in landing gear, actuators, or control systems, our wire is designed to handle the stress and environmental challenges of flight.

What makes our Monel 400 wire special is its ability to resist corrosion from acids, alkalis, and even seawater, while maintaining performance at temperatures up to 1000°F (538°C). It’s also non-magnetic, which is a big deal for aerospace applications where magnetic interference can disrupt sensitive systems like avionics. We offer full customization—think tailored diameters, tensile strengths, and finishes—to ensure our wire fits your specific needs like a glove.

Monel 400 and Monel K-500 Spring Wire Parameter Table

Parameter | Monel 400 | Monel K-500 |

|---|---|---|

Material | Nickel-Copper alloy (solid-solution strengthened, hardenable only by cold working) | Nickel-Copper alloy (age-hardenable, with added aluminum and titanium for enhanced strength and hardness) |

Specifications | AMS 7233, ASTM B164, UNS N04400, QQ-N-281 | AMS 4676, ASTM B865, UNS N05500, BS 3075 NA 18, NACE MR0175, QQ-N-286 |

Chemical Composition | Ni: ≥63% | Ni: 63-70% |

Tensile Strength | Annealed: 70-110 ksi (480-760 MPa) | Annealed: 80-110 ksi (550-760 MPa) |

Density | 8.80 g/cm³ (0.318 lb/in³) | 8.44 g/cm³ (0.305 lb/in³) |

Max Operating Temperature | 815°C (1500°F), recommended for springs ≤450°F (232°C) | 450°F (232°C), suitable for -184°C to 232°C (-300°F to 450°F) |

Hardness | Rockwell C23-32 (spring temper) | Rockwell C30-40 (spring temper + aged) |

Wire Diameter | 0.10 mm - 14 mm | 0.10 mm - 14 mm |

Applications | Marine engineering (fasteners, valves, pumps, propeller shafts), chemical processing equipment, electronic components, petroleum distillation towers | Marine engineering (pump shafts, fasteners, propeller shafts), oil and gas industry, chemical processing, medical equipment, aerospace |

For more details, pls directly contact us.

We’ve engineered our Monel 400 Spring Wire to stand up to the toughest aerospace challenges. Here’s why it’s a cut above:

Unmatched Corrosion Resistance: From exposure to jet fuel to salty coastal air, our wire resists corrosion like a champ, ensuring long-lasting springs.

High Strength and Durability: With tensile strengths of 70-110 ksi, our wire delivers reliable performance under high stress and fatigue.

Fully Customizable: Need a specific coil design or tensile strength? We tailor every aspect to meet your aerospace project’s requirements.

Non-Magnetic Properties: Ideal for avionics and other sensitive systems where magnetic interference is a no-go.

Extreme Temperature Performance: From freezing altitudes to high-heat engine environments, our wire keeps its strength and flexibility.

Compared to other companies, we shine with our commitment to precision and quality. While others might offer similar alloys, we go the extra mile with rigorous quality control, faster lead times, and expert technical support. Our team works closely with you to ensure your springs are built to spec, whether it’s for a prototype or full-scale production.

Applications of Monel 400 Spring Wire

Our Monel 400 Spring Wire is a workhorse in aerospace and beyond. Here’s where it’s making an impact:

Landing Gear Systems: Springs in landing gear need to handle extreme stress and corrosion from environmental exposure. Our wire delivers.

Actuators and Valves: Precision springs in actuators and fuel systems rely on our wire’s strength and corrosion resistance.

Control Systems: Non-magnetic springs in avionics and control systems ensure no interference with sensitive electronics.

Engine Components: Our wire withstands high temperatures and corrosive jet fuel, making it ideal for engine springs.

Spacecraft Components: From satellites to space exploration vehicles, our wire supports lightweight, durable springs in extreme conditions.

Industry Trends Driving Monel 400 Demand

The aerospace industry is evolving fast, and our Monel 400 Spring Wire is right in step with the changes. One big trend is the push for lightweight, durable materials. With fuel efficiency and sustainability at the forefront, aerospace manufacturers need components that are both strong and long-lasting. Our Monel 400 wire fits the bill, offering high strength without adding unnecessary weight, plus corrosion resistance that reduces maintenance costs.

Another trend is the rise of advanced aerospace technologies, like next-gen aircraft and space exploration systems. These projects demand materials that can handle extreme conditions, from subzero temperatures in high-altitude flights to the heat of re-entry. Our Monel 400 wire is built for these challenges, providing reliability where failure isn’t an option.

Customization is also a growing focus. Aerospace designs are getting more complex, with tighter tolerances and unique requirements. Our ability to deliver custom wire specifications—down to the exact diameter or tensile strength—gives us an edge, ensuring our springs integrate seamlessly into cutting-edge aerospace systems.

Comparison Table: Monel 400 vs. Stainless Steel vs. Inconel 718 for Aerospace Springs

Parameter | Monel 400 | Stainless Steel (17-4 PH) | Inconel 718 |

|---|---|---|---|

Composition | Nickel (67%), Copper (23%), Iron, Manganese | Iron, Chromium (15-17%), Nickel (3-5%) | Nickel (50-55%), Chromium (17-21%), Molybdenum |

Corrosion Resistance | Excellent (seawater, acids, alkalis) | Good (general corrosion, moderate environments) | Excellent (high-temperature, oxidation) |

Temperature Range | Up to 1000°F (538°C) | Up to 600°F (316°C) | Up to 1300°F (704°C) |

Tensile Strength | 70-110 ksi (480-760 MPa) | 160-190 ksi (1103-1310 MPa) | 180-220 ksi (1241-1517 MPa) |

Non-Magnetic | Yes | Slightly magnetic (after heat treatment) | Yes |

Cost | Moderate | Moderate | High |

Best Applications | Aerospace, marine, chemical processing | General aerospace, structural components | High-temperature aerospace, turbines |

Fatigue Resistance | High | High | Very High |

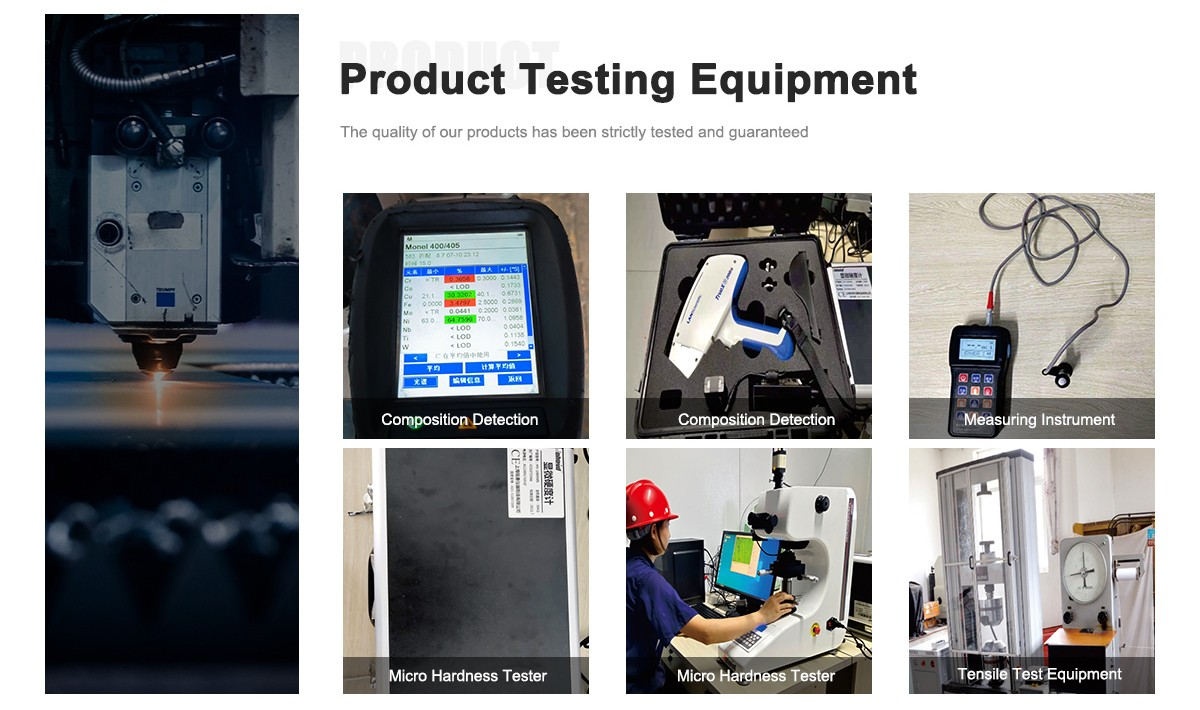

When you choose our Monel 400 Spring Wire, you’re getting more than just a product—you’re getting a partner. Our competitors might offer similar materials, but we stand out with our obsession with quality. Every batch of wire goes through strict testing to ensure it meets aerospace standards, so you can trust it to perform in critical applications.

We also know that time is critical in aerospace projects. Our streamlined production and delivery processes get your wire to you faster, without compromising on quality. Need help with specs? Our technical team is on hand to guide you, ensuring your springs are perfectly suited to your needs, whether it’s a small batch for testing or a large order for production.

Innovation is at the heart of what we do. We’re constantly exploring ways to improve our Monel 400 wire, from enhancing fatigue resistance to offering new customization options. This keeps us ahead of the competition and ensures our customers have access to the latest advancements in spring wire technology.

The Future of Monel 400 Spring Wire

The future is bright for Monel 400 Spring Wire, especially in aerospace. As the industry pushes toward more sustainable, efficient aircraft and expands into space exploration, the demand for high-performance materials will only grow. Our wire is ready to meet these challenges, offering the durability and corrosion resistance needed for next-gen aerospace systems.

We’re also investing in the future. Our R&D team is working on new ways to optimize Monel 400 wire, from improving its performance in extreme conditions to developing new manufacturing techniques. Our goal is to stay ahead of industry needs, delivering springs that power the aircraft and spacecraft of tomorrow.

Why Monel 400 is Your Go-To for Aerospace Springs

Our Durable Monel 400 Spring Wire for Aerospace Components is built to perform where others can’t. Its corrosion resistance, high strength, and customizability make it the perfect choice for critical aerospace applications, from landing gear to avionics. With our focus on quality, fast delivery, and expert support, you’re getting a solution that’s tailored to your needs and built to last.

Whether you’re designing a new aircraft, upgrading existing systems, or pushing the boundaries of space exploration, our Monel 400 springs are ready to deliver. Ready to take your project to the next level? Let’s talk about how our wire can make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Monel 400 Spring Wire made of?

Monel 400 is a nickel-copper alloy with about 67% nickel, 23% copper, and small amounts of iron and manganese for enhanced strength and corrosion resistance.Why is Monel 400 suitable for aerospace components?

Its high strength, corrosion resistance, and ability to perform in extreme temperatures make it ideal for aerospace springs in demanding environments.What aerospace applications use Monel 400 Spring Wire?

Springs in landing gear, actuators, valves, and control systems where durability and corrosion resistance are critical.Can Monel 400 Spring Wire handle high temperatures?

Yes, it maintains performance in temperatures up to 1000°F (538°C), perfect for aerospace conditions.Is Monel 400 Spring Wire non-magnetic?

Yes, its non-magnetic properties are ideal for aerospace applications requiring minimal magnetic interference.What customization options are available for Monel 400 springs?

We offer custom diameters, tensile strengths, coil designs, and finishes to meet specific aerospace requirements.How does Monel 400 compare to stainless steel for aerospace springs?

Monel 400 offers better corrosion resistance and durability in extreme environments compared to stainless steel, with longer service life.What industries benefit from Monel 400 Spring Wire?

Aerospace, marine, chemical processing, and oil and gas industries rely on its strength and corrosion resistance.