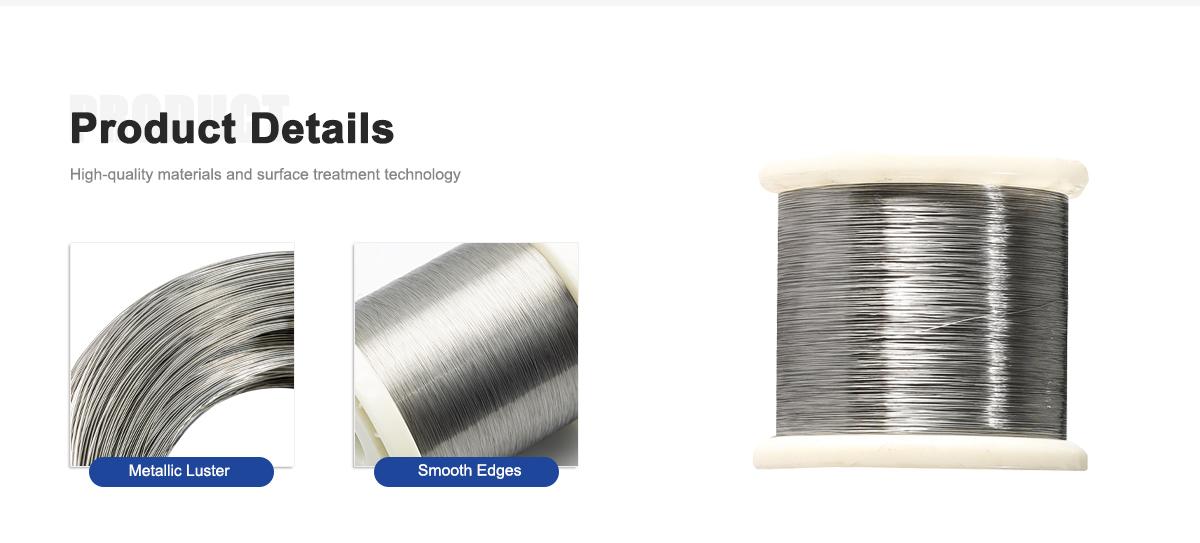

Monel 400 Spring Wire for Harsh Environment Applications

Our Monel 400 Spring Wire for Harsh Environment Applications is built to thrive where conditions get brutal. From corrosive chemical plants to salty offshore rigs, this wire delivers the strength, durability, and reliability you need for springs that stand up to the toughest challenges. Let’s dive into what makes our Monel 400 spring wire a top pick, explore its applications, and check out the trends driving its demand across industries.

For more details, pls directly contact us.

Our Monel 400 Spring Wire is crafted from a nickel-copper alloy, blending about 67% nickel with 23% copper, plus a touch of iron and manganese for extra toughness. This mix gives it unmatched corrosion resistance against harsh elements like seawater, acids, and alkalis, making it a go-to for springs in extreme environments. It’s strong, reliable, and built to last, no matter how tough the conditions.

This wire is a champ in harsh settings. It handles temperatures up to 1000°F (538°C), resists pitting and crevice corrosion, and stays non-magnetic, which is a big win for sensitive equipment like sensors or electronics. We offer full customization—think tailored diameters, tensile strengths, coil designs, and finishes—so you get springs that fit your project perfectly, whether it’s for a chemical reactor or an offshore platform.

Monel 400 and Monel K-500 Spring Wire Parameter Table

Parameter | Monel 400 | Monel K-500 |

|---|---|---|

Material | Nickel-Copper alloy (solid-solution strengthened, hardenable only by cold working) | Nickel-Copper alloy (age-hardenable, with added aluminum and titanium for enhanced strength and hardness) |

Specifications | AMS 7233, ASTM B164, UNS N04400, QQ-N-281 | AMS 4676, ASTM B865, UNS N05500, BS 3075 NA 18, NACE MR0175, QQ-N-286 |

Chemical Composition | Ni: ≥63% | Ni: 63-70% |

Tensile Strength | Annealed: 70-110 ksi (480-760 MPa) | Annealed: 80-110 ksi (550-760 MPa) |

Density | 8.80 g/cm³ (0.318 lb/in³) | 8.44 g/cm³ (0.305 lb/in³) |

Max Operating Temperature | 815°C (1500°F), recommended for springs ≤450°F (232°C) | 450°F (232°C), suitable for -184°C to 232°C (-300°F to 450°F) |

Hardness | Rockwell C23-32 (spring temper) | Rockwell C30-40 (spring temper + aged) |

Wire Diameter | 0.10 mm - 14 mm | 0.10 mm - 14 mm |

Applications | Marine engineering (fasteners, valves, pumps, propeller shafts), chemical processing equipment, electronic components, petroleum distillation towers | Marine engineering (pump shafts, fasteners, propeller shafts), oil and gas industry, chemical processing, medical equipment, aerospace |

For more details, pls directly contact us.

We’ve designed our Monel 400 Spring Wire to be a game-changer for harsh environment applications. Here’s why it’s a cut above:

Top-Notch Corrosion Resistance: Seawater, acids, and alkalis don’t stand a chance. Our wire keeps springs corrosion-free in the toughest conditions.

High Strength and Durability: With tensile strengths of 70-110 ksi, our wire handles heavy loads and stress without losing its edge.

Custom-Built for You: From precision springs for sensors to heavy-duty ones for drilling rigs, we tailor every detail to your specs.

Non-Magnetic Properties: Perfect for sensitive applications like instrumentation where magnetic interference could cause issues.

Extreme Versatility: From freezing cold to scorching heat, our wire delivers reliable performance in any harsh environment.

Compared to other companies, we’re all about precision and reliability. While others might offer similar alloys, we stand out with tighter quality control, faster delivery, and hands-on technical support. Our team works with you to ensure your springs are spot-on, whether you’re building a prototype or scaling up for production.

Applications of Monel 400 Spring Wire

Our Monel 400 Spring Wire is a workhorse across a range of industries facing harsh conditions. Here’s where it’s making a difference:

Chemical Processing: Springs in reactors, valves, and pumps deal with corrosive chemicals daily. Our wire keeps them running strong.

Marine Hardware: From ship valves to offshore platforms, our springs resist seawater corrosion and perform reliably under stress.

Oil and Gas: Springs in drilling equipment, pipelines, and refineries rely on our wire’s strength and corrosion resistance in harsh environments.

Aerospace: Lightweight, durable springs in landing gear, actuators, and avionics benefit from our wire’s performance in extreme conditions.

Power Generation: Springs in turbines and generators handle high temperatures and corrosive environments, and our wire delivers.

Industry Trends Driving Monel 400 Demand

The industrial world is changing fast, and our Monel 400 Spring Wire is right in step with the trends. One big shift is the focus on sustainability. Companies want materials that last longer to cut down on replacements and maintenance costs. Our Monel 400 wire is a perfect match—its durability means less downtime, fewer resources wasted, and a smaller environmental footprint.

Another trend is the push into harsher operating environments. As industries like oil and gas, chemical processing, and marine engineering tackle more extreme conditions—think deep-sea drilling or aggressive chemical plants—the demand for corrosion-resistant, high-strength materials is soaring. Our Monel 400 wire is built for these challenges, offering the reliability needed for next-gen systems.

Precision engineering is also a key focus. With more complex designs and tighter tolerances, industries need materials that can be customized without sacrificing performance. Our ability to deliver tailored wire specs—down to the exact diameter or coil design—gives us an edge, ensuring our springs integrate seamlessly into cutting-edge applications.

Comparison Table: Monel 400 vs. Stainless Steel vs. Hastelloy C-276 for Harsh Environment Springs

Parameter | Monel 400 | Stainless Steel (316) | Hastelloy C-276 |

|---|---|---|---|

Composition | Nickel (67%), Copper (23%), Iron, Manganese | Iron, Chromium (16-18%), Nickel (10-14%) | Nickel (57%), Molybdenum (15-17%), Chromium |

Corrosion Resistance | Excellent (seawater, acids, alkalis) | Good (general corrosion, some chemicals) | Excellent (acids, high-temperature) |

Temperature Range | Up to 1000°F (538°C) | Up to 870°F (465°C) | Up to 1900°F (1038°C) |

Tensile Strength | 70-110 ksi (480-760 MPa) | 75-90 ksi (515-620 MPa) | 100-150 ksi (690-1034 MPa) |

Non-Magnetic | Yes | Yes (austenitic grades) | Yes |

Cost | Moderate | Low | High |

Best Applications | Marine, chemical, oil and gas, aerospace | General industrial, less corrosive uses | Extreme chemical, high-temperature uses |

Fatigue Resistance | High | Moderate | Very High |

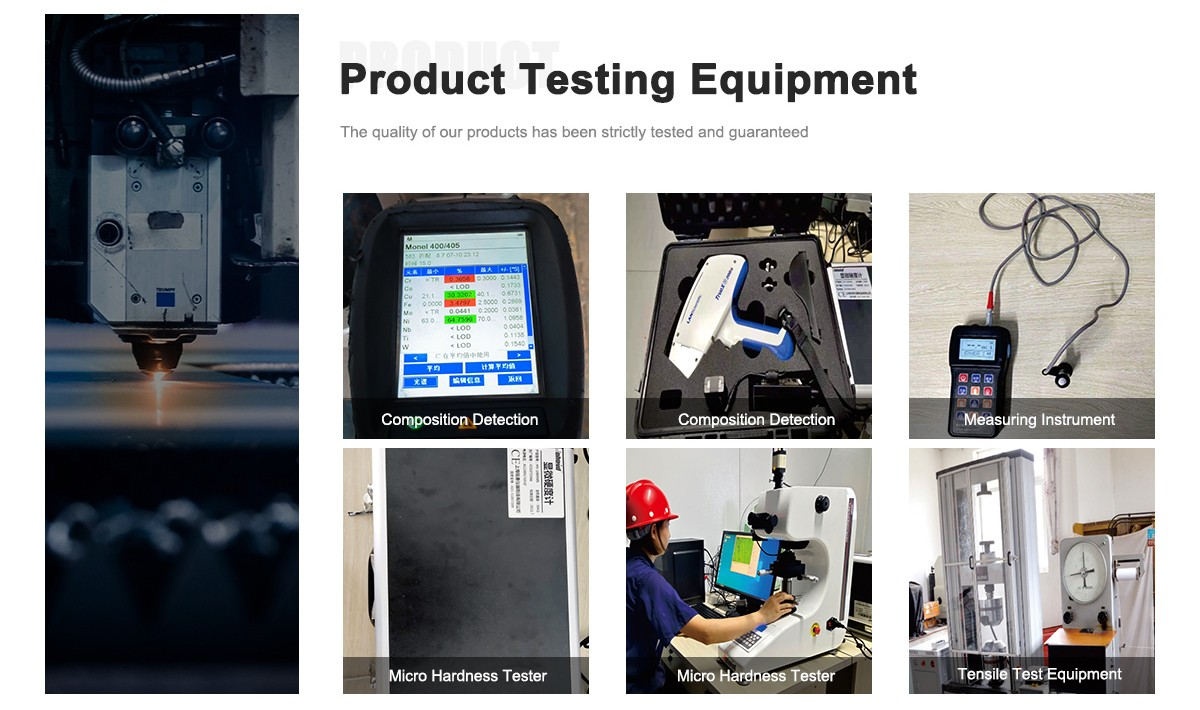

Choosing our Monel 400 Spring Wire means choosing a partner who’s obsessed with quality. Our competitors might offer similar products, but we go the extra mile with rigorous quality control at every step. From sourcing raw materials to final production, we ensure every batch meets the highest standards, so you can trust it to perform in critical applications.

We know downtime is a killer in any industry. That’s why we’ve streamlined our production and logistics to deliver your wire faster, without skimping on quality. Need help picking the right specs? Our technical team is ready to jump in, ensuring your springs are perfectly suited to your project, whether it’s a small test run or a large-scale order.

Innovation is at the core of what we do. We’re constantly exploring ways to improve our Monel 400 wire, from boosting fatigue resistance to offering new customization options. This keeps us ahead of the pack and ensures you’re getting the latest advancements in spring wire technology.

The Future of Monel 400 Spring Wire

The future is looking strong for Monel 400 Spring Wire, especially in harsh environment applications. As industries push for more efficient, sustainable operations, the demand for durable, corrosion-resistant materials will keep growing. Our wire is ready to meet these needs, offering the strength and reliability required for everything from chemical plants to offshore rigs to aerospace systems.

We’re also investing in what’s next. Our R&D team is working on ways to make our Monel 400 wire even better, whether it’s through advanced manufacturing techniques or tweaking the alloy for enhanced performance. We’re not just keeping up with industry demands—we’re setting the standard for what’s possible.

Why Monel 400 is Your Go-To for Harsh Environments

Our Monel 400 Spring Wire for Harsh Environment Applications is built to handle the toughest challenges across industries. Its corrosion resistance, high strength, and customizability make it the perfect choice for springs in chemical processing, marine, oil and gas, and aerospace applications. With our focus on quality, fast delivery, and expert support, you’re getting a solution that’s tailored to your needs and built to last.

Whether you’re designing springs for a corrosive chemical plant, a high-pressure offshore rig, or a precision aerospace system, our Monel 400 wire has you covered. Ready to see how it can power your next project? Let’s get to work and build something that stands up to the toughest conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Monel 400 Spring Wire made of?

Monel 400 is a nickel-copper alloy with about 67% nickel, 23% copper, and small amounts of iron and manganese for enhanced strength and corrosion resistance.Why is Monel 400 suitable for harsh environments?

Its exceptional resistance to corrosive elements like seawater, acids, and alkalis makes it ideal for springs in extreme conditions.What applications use Monel 400 Spring Wire in harsh environments?

Springs in chemical processing, marine hardware, oil and gas equipment, and aerospace systems exposed to corrosive or high-stress conditions.Can Monel 400 Spring Wire handle extreme temperatures?

Yes, it performs reliably up to 1000°F (538°C), maintaining strength and corrosion resistance in tough environments.Is Monel 400 Spring Wire non-magnetic?

Yes, its non-magnetic properties make it perfect for sensitive equipment like sensors and instrumentation in harsh settings.What customization options are available for Monel 400 springs?

We offer custom diameters, tensile strengths, coil designs, and finishes to meet specific requirements for harsh environment applications.How does Monel 400 compare to stainless steel for harsh environment springs?

Monel 400 offers superior corrosion resistance in aggressive environments like seawater and acids, with better durability than stainless steel.What industries benefit from Monel 400 Spring Wire?

Chemical processing, marine, oil and gas, aerospace, and power generation industries rely on its performance in extreme conditions.