Monel K500 Spring Wire for Robust Aerospace Landing Gear

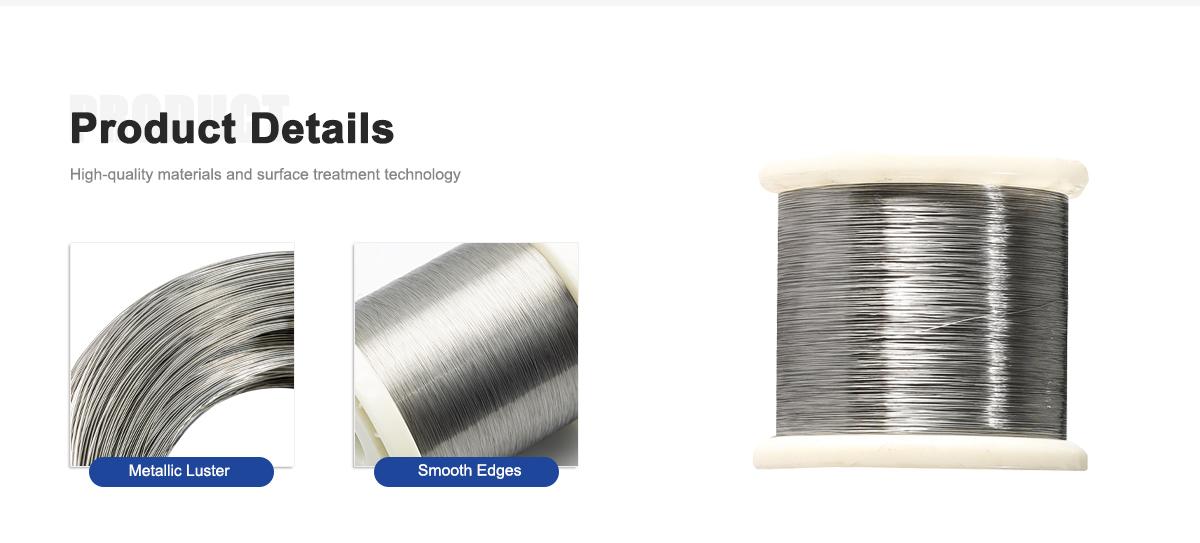

Our Monel K500 spring wire is a total beast for aerospace landing gear, built to deliver unmatched strength and durability in the toughest conditions. This nickel-copper alloy, with about 65% nickel, 30% copper, and a kick from aluminum and titanium, is our top pick for high-stress applications where failure isn’t an option. Whether you’re designing landing gear springs or fasteners for aircraft, this wire’s got your back.

What makes Monel K500 spring wire stand out is its incredible mechanical strength and hardness. The aluminum and titanium additions give it a serious edge, making it perfect for landing gear springs that need to handle intense loads, vibrations, and fatigue during takeoffs and landings. It’s also corrosion-resistant, shrugging off saltwater, humidity, and acidic environments, which is a big deal for aircraft operating in coastal or harsh weather conditions.

This wire’s versatility is a game-changer. It’s stable up to 650°C, which is plenty for aerospace components exposed to moderate heat, like those near engines or hydraulic systems. Its moderate electrical conductivity (~3-4% IACS) is useful for applications with electrical integration, and its high fatigue resistance ensures it keeps performing under repeated stress. From commercial jets to military aircraft, Monel K500 delivers reliability.

We love how workable this wire is, even with its extra toughness. You can coil, shape, or weld it into whatever your landing gear design needs—tight springs or heavy-duty fasteners. Need a custom diameter, tensile strength, or coil spec? We can tailor it to fit your project perfectly, keeping your production on track and your components top-notch.

The aerospace industry’s pushing for materials that are strong, lightweight, and sustainable, and Monel K500 spring wire fits right in. It’s recyclable, which is awesome for eco-friendly projects, and its long lifespan means less waste from replacements. With global air travel growing—think new aircraft fleets and urban air mobility—demand for high-performance materials like Monel K500 is soaring. Its durability also supports the trend toward low-maintenance, fuel-efficient aircraft designs.

Monel 400 and Monel K-500 Spring Wire Parameter Table

|

Parameter |

Monel 400 |

Monel K-500 |

|---|---|---|

|

Material |

Nickel-Copper alloy (solid-solution strengthened, hardenable only by cold working) |

Nickel-Copper alloy (age-hardenable, with added aluminum and titanium for enhanced strength and hardness) |

|

Specifications |

AMS 7233, ASTM B164, UNS N04400, QQ-N-281 |

AMS 4676, ASTM B865, UNS N05500, BS 3075 NA 18, NACE MR0175, QQ-N-286 |

|

Chemical Composition |

Ni: ≥63% |

Ni: 63-70% |

|

Tensile Strength |

Annealed: 70-110 ksi (480-760 MPa) |

Annealed: 80-110 ksi (550-760 MPa) |

|

Density |

8.80 g/cm³ (0.318 lb/in³) |

8.44 g/cm³ (0.305 lb/in³) |

|

Max Operating Temperature |

815°C (1500°F), recommended for springs ≤450°F (232°C) |

450°F (232°C), suitable for -184°C to 232°C (-300°F to 450°F) |

|

Hardness |

Rockwell C23-32 (spring temper) |

Rockwell C30-40 (spring temper + aged) |

|

Wire Diameter |

0.10 mm - 14 mm |

0.10 mm - 14 mm |

|

Applications |

Marine engineering (fasteners, valves, pumps, propeller shafts), chemical processing equipment, electronic components, petroleum distillation towers |

Marine engineering (pump shafts, fasteners, propeller shafts), oil and gas industry, chemical processing, medical equipment, aerospace |

For more details, pls directly contact us.

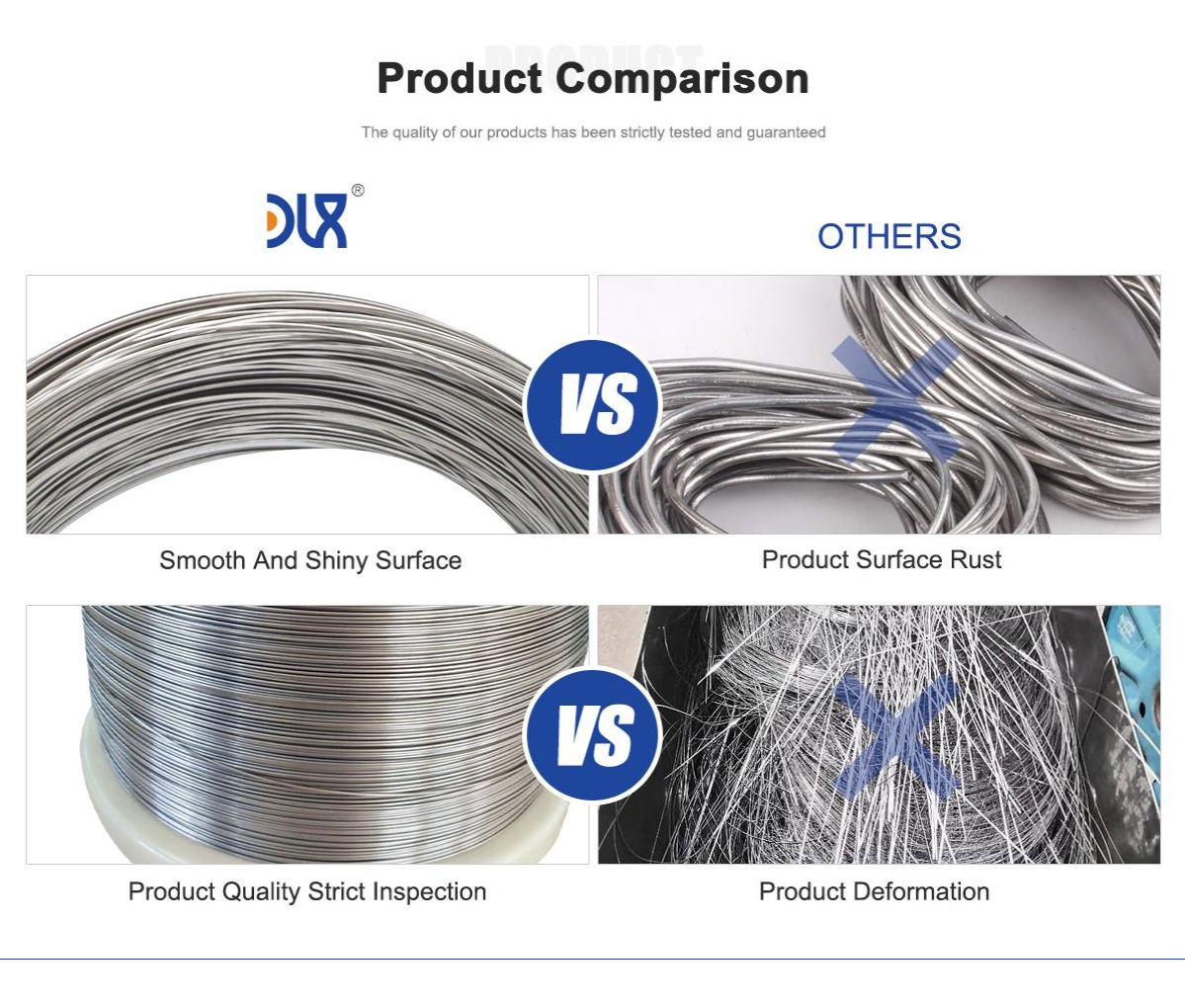

Our Monel K500 spring wire sets the standard because we’re laser-focused on quality, customization, and customer success. We offer a wide range of diameters, tensile strengths, and coil specs, with fast delivery for both small and large orders. Our team dives into your project, optimizing the wire for your specific landing gear components to ensure peak strength and corrosion resistance. We keep pricing competitive, especially for bulk orders, without ever cutting corners on quality. Our sustainable production process uses recyclable materials, aligning with green aerospace trends. Plus, our hands-on support means you’re always covered—whether it’s technical guidance or a custom solution, we make it happen.

Compared to other materials, our Monel K500 spring wire is a standout. Monel 400 is great for corrosion resistance but lacks K500’s strength for high-stress aerospace applications. Stainless steel 17-7 PH is tough but struggles with chloride corrosion, unlike K500. Titanium alloys are lightweight but pricier and less fatigue-resistant in some cases. Our wire is the ultimate choice for robust aerospace landing gear.

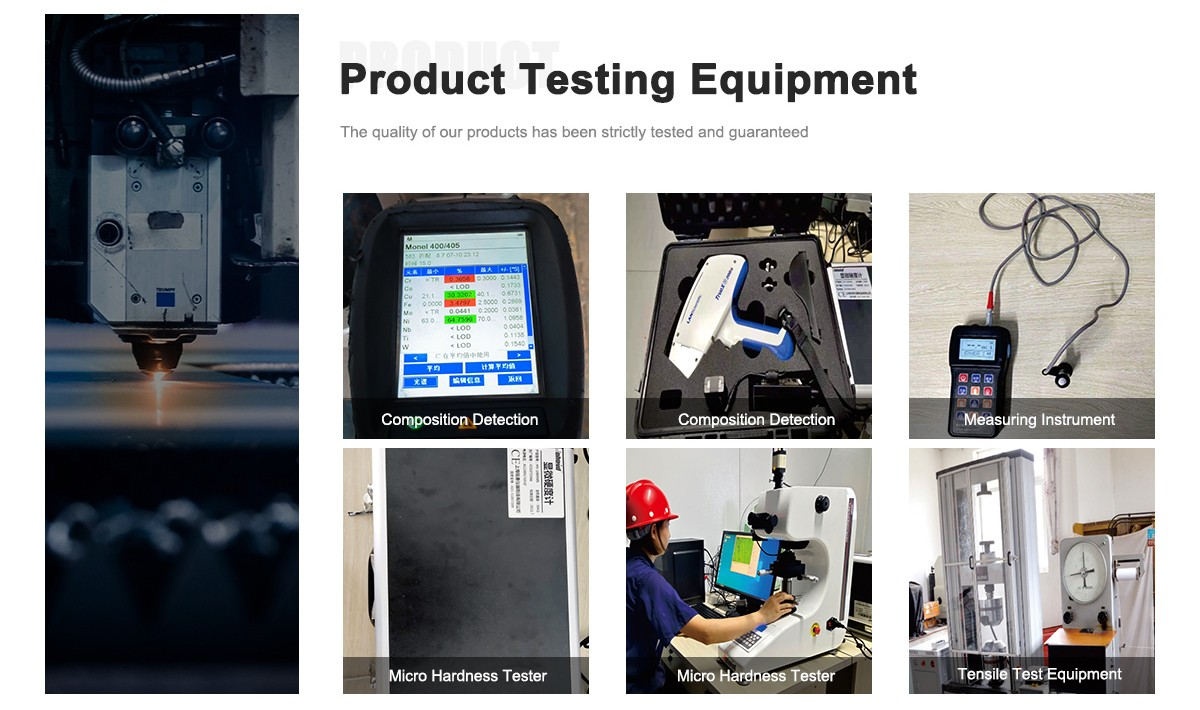

We craft our Monel K500 spring wire to meet strict standards like ISO 9001, ensuring quality you can trust every time. Whether you’re building springs for commercial jets or military aircraft, this wire’s ready to perform. Got a unique spec in mind? Let us know, and we’ll make it happen.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Monel K500 spring wire made of?

It’s a nickel-copper alloy with about 65% nickel, 30% copper, plus aluminum and titanium for high strength and hardness. -

What are the main uses for Monel K500 spring wire in aerospace?

It’s used for robust landing gear springs, fasteners, and components in aircraft exposed to high stress and corrosive environments. -

How does Monel K500 spring wire perform in aerospace conditions?

It’s a powerhouse, resisting corrosion and delivering high strength under extreme mechanical stress and fatigue. -

Can Monel K500 spring wire handle high temperatures?

Yes, it’s stable up to 650°C, ideal for aerospace components facing moderate to high heat. -

Is Monel K500 spring wire cost-effective?

It’s pricier than Monel 400, but its strength and durability in aerospace applications make it a smart long-term choice. -

How does Monel K500 spring wire compare to Monel 400 spring wire?

K500 offers higher strength and hardness, while Monel 400 has slightly better corrosion resistance but less mechanical toughness. -

Can Monel K500 spring wire be customized?

Totally! We can adjust diameter, tensile strength, or coil specs to meet your specific aerospace landing gear needs. -

Is Monel K500 spring wire environmentally friendly?

It’s recyclable, supporting sustainable practices, and its durability reduces waste from frequent replacements.