Corrosion-Resistant CuNi Wire for Reliable Performance

Our CuNi wire is the kind of material you can count on when things get tough. This copper-nickel alloy is engineered to resist corrosion like a champ, making it a top choice for projects where reliability is non-negotiable. Whether it’s battling saltwater or powering precision electronics, our CuNi wire gets the job done.

Corrosion resistance is where this wire really shines. The nickel content—ranging from 10% in CuNi1 0 to 44% in CuNi44—teams up with additives like iron to fend off rust and degradation, even in brutal environments like marine or chemical plants. It’s why you’ll find our wire in ship wiring, offshore rigs, and desalination systems, holding strong where other materials would crumble.

But it’s not just about fighting corrosion. CuNi wire delivers rock-solid electrical performance, with consistent resistivity that’s perfect for resistors, thermocouples, and other precision components. It’s a favorite in electronics and aerospace because it doesn’t skip a beat, even under stress. Plus, it can handle heat like a pro, staying stable up to 400°C, or even 500°C for certain grades, so it’s great for industrial heating systems.

We love how easy this wire is to work with. It’s super workable, meaning you can bend, weld, or shape it without breaking a sweat. Need it in a specific form, like a ribbon or strip? Or a particular nickel blend? We can customize it to fit your needs, making it a versatile pick for everything from energy projects to communication cables.

The industry’s moving toward materials that are both high-performing and sustainable, and CuNi wire fits right in. It’s recyclable, which is a win for eco-friendly initiatives, and its long lifespan means less waste and fewer replacements. As marine and energy sectors demand tougher, longer-lasting solutions, CuNi wire is stepping up as a go-to material.

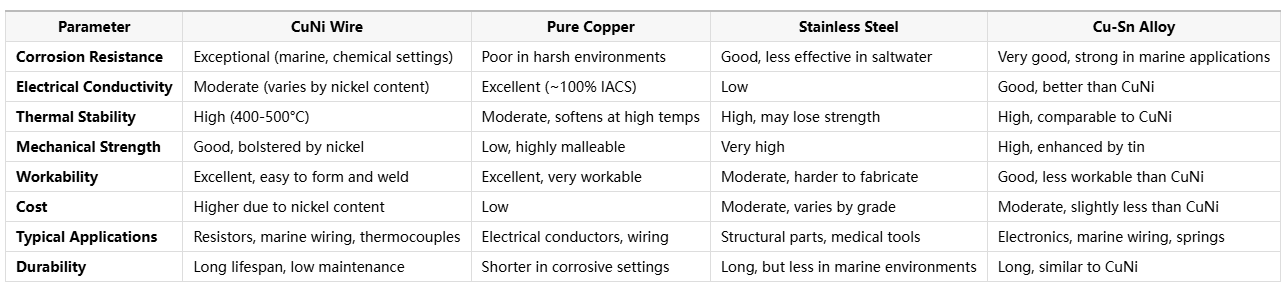

Compared to other options, CuNi wire has a unique edge. Pure copper’s great for conductivity but falls apart in corrosive settings. Stainless steel’s tough but lacks the electrical properties needed for many applications. Cu-Sn alloys are solid, but CuNi often outperforms them in marine environments and precision tasks.

We produce our CuNi wire to meet rigorous standards like ISO 9001, so you know you’re getting quality you can trust. Whether you’re wiring a ship or building cutting-edge electronics, our wire’s ready to deliver reliable performance. Got a specific requirement? Let us know, and we’ll tailor it for you.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 | |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 | |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

Comparison Parameters Table

About Us:

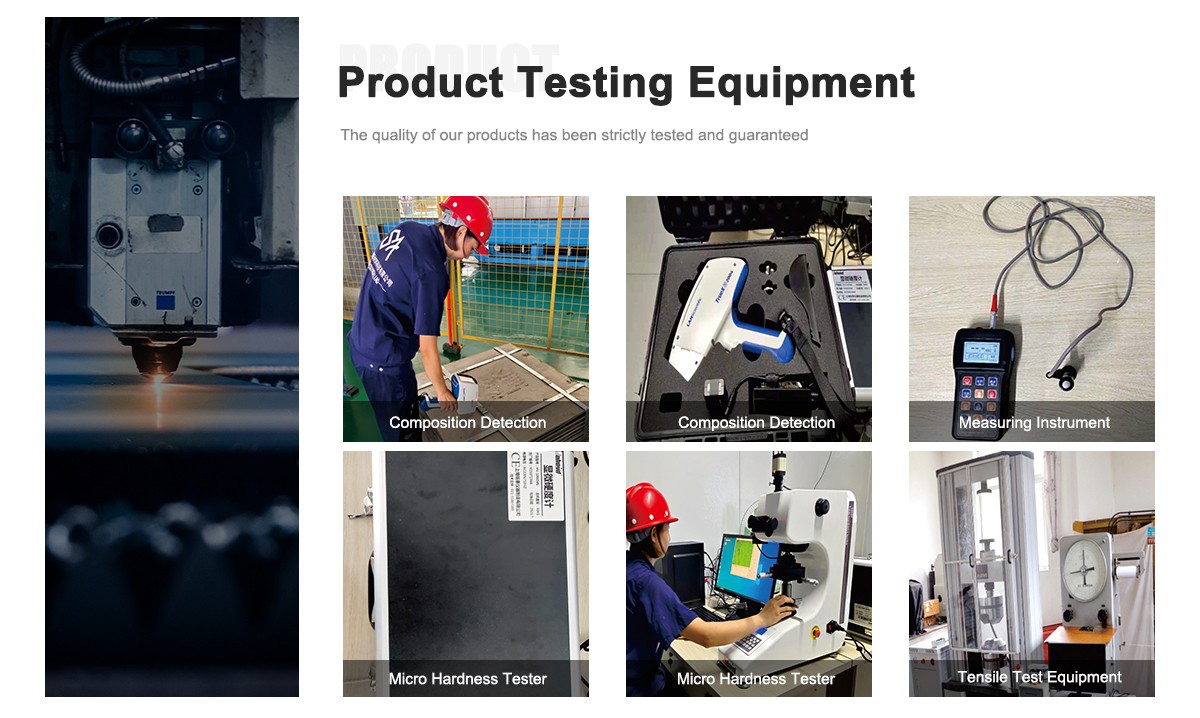

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What gives CuNi wire its corrosion resistance?

The nickel in the copper-nickel alloy, often combined with iron or manganese, creates a protective barrier that fights off corrosion, especially in saltwater and chemical environments.

What industries use CuNi wire?

It’s big in marine, aerospace, electronics, and energy sectors for things like ship wiring, resistors, thermocouples, and offshore equipment.

How does CuNi wire hold up in marine settings?

It’s practically made for the ocean—resisting saltwater corrosion better than most metals, which makes it perfect for marine hardware and coastal installations.

Is CuNi wire good for high-heat applications?

Totally, it stays stable up to 400°C for most grades, and some like CuNi30Mn can hit 500°C, ideal for heating elements and industrial furnaces.

How does CuNi wire compare cost-wise?

It’s more expensive than pure copper due to nickel, but its longevity and low maintenance make it a cost-effective choice for critical systems.

Can CuNi wire be used in electrical circuits?

Yes, its stable resistivity makes it great for resistors, potentiometers, and other precision electrical components.

Can you customize CuNi wire for specific needs?

For sure! We offer different nickel contents (like CuNi10 or CuNi44) and forms (wire, strip, ribbon) to match your project’s requirements.

Is CuNi wire eco-friendly?

It’s recyclable, aligning with sustainable practices, and its durability means fewer replacements, reducing environmental impact.