Durable CuNi Alloy Wire for Industrial and Marine Use

Our CuNi alloy wire is built to take a beating and keep on performing, whether it’s in the salty spray of a marine rig or the intense heat of an industrial furnace. This copper-nickel alloy is one of our toughest offerings, and we’re stoked to share why it’s a top pick for heavy-duty applications.

Let’s talk durability first. CuNi wire laughs in the face of corrosion, especially in saltwater or chemical-heavy environments. With nickel content ranging from 10% to 44%, plus extras like iron in CuNi10Fe, this wire holds strong where others would rust away. That’s why it’s a go-to for shipbuilding, offshore platforms, and chemical plants.

It’s not just about surviving tough conditions—CuNi wire is made to last. Its mechanical strength and long service life mean you’re not constantly replacing parts or dealing with downtime. We’ve seen it used in everything from marine hardware to industrial resistors, and it just keeps going with minimal upkeep. That’s money saved in the long run, even if the upfront cost is a bit higher than plain copper.

The wire’s also super versatile. It’s highly formable, so you can bend, weld, or shape it without a fuss, which is a big win for manufacturers. Need a specific size or nickel blend? We’ve got you covered with custom options like CuNi10 or CuNi44, tailored for your project. It’s perfect for heating cables, electrical components, or even precision parts in oil and gas setups.

Industry trends are pushing for materials that are both high-performance and sustainable, and CuNi wire checks both boxes. It’s fully recyclable, which is great for green initiatives, and its durability means less waste over time. As industries like marine and energy lean into longer-lasting solutions, CuNi is becoming a no-brainer choice.

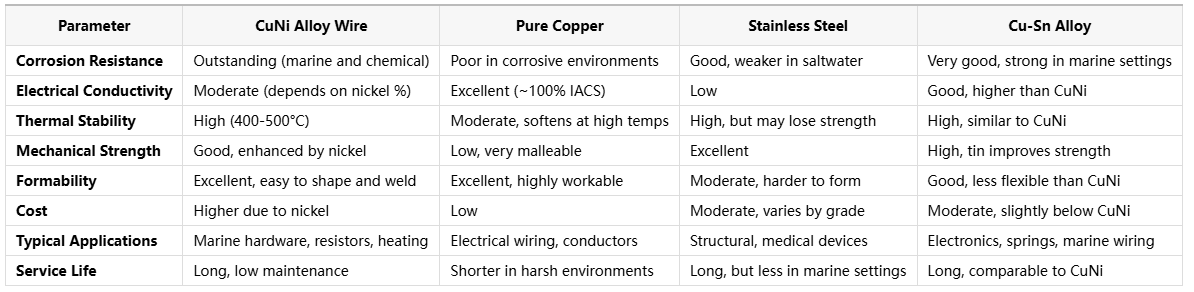

Compared to other materials, CuNi alloy wire stands out. Pure copper’s awesome for conductivity but flops in corrosive settings. Stainless steel’s tough but lacks CuNi’s electrical properties and marine-grade corrosion resistance. Cu-Sn alloys are close competitors, but CuNi often wins for its balance of formability and reliability in extreme conditions.

We craft our CuNi wire to meet strict standards like ISO 9001, ensuring you get consistent quality every time. Whether you’re outfitting a ship or building industrial gear, our wire’s ready to deliver. Got a unique spec in mind? Let us know, and we’ll make it happen.

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 | |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 | |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 | |

CuNi34 | 0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

Comparison Parameters Table

About Us:

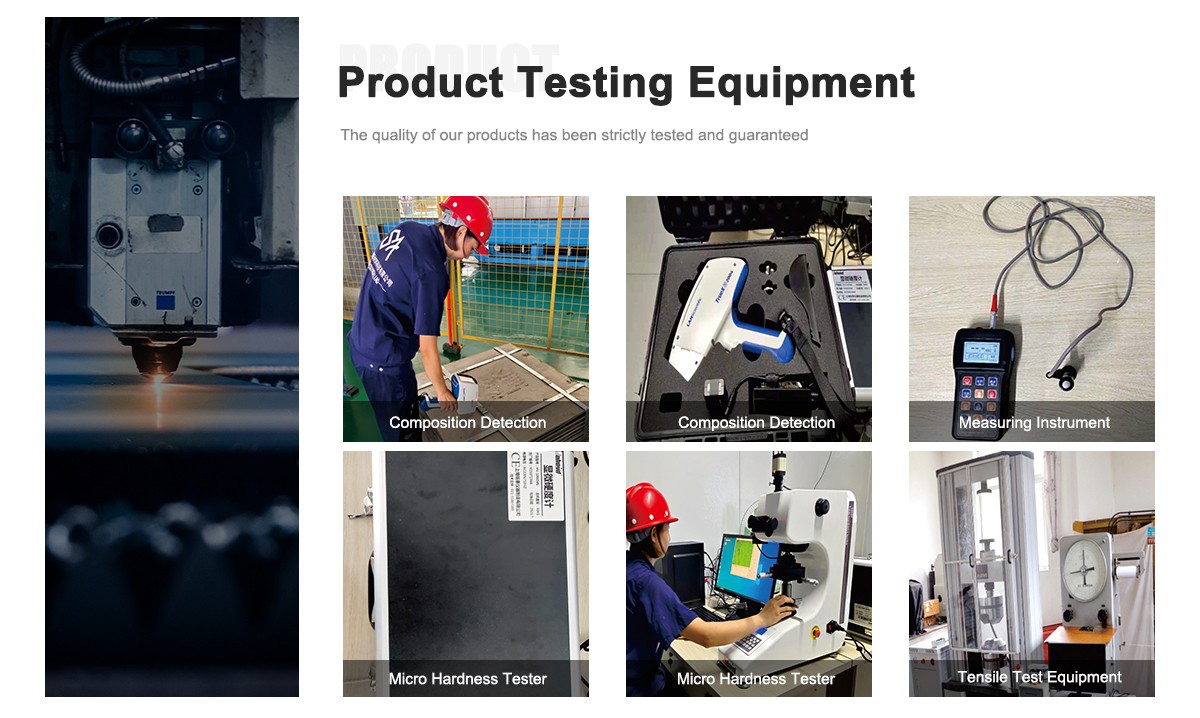

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What makes CuNi alloy wire so durable?

The copper-nickel alloy, often with iron or manganese additives, gives it exceptional strength and resistance to wear, especially in corrosive settings like seawater or industrial chemicals.Where is CuNi alloy wire typically used?

It’s a staple in marine hardware, industrial heating systems, electrical resistors, and components for oil and gas, shipbuilding, and chemical processing industries.How does CuNi alloy wire perform in saltwater?

It’s a rock star in marine environments, resisting corrosion from saltwater better than most metals, which is why it’s used in ship wiring and offshore platforms.Can CuNi alloy wire withstand high temperatures?

Yep, most grades handle up to 400°C, with some like CuNi30Mn pushing 500°C, making it ideal for industrial furnaces and heating elements.Is CuNi alloy wire cost-effective?

While it costs more upfront than pure copper or steel, its long lifespan and low maintenance make it a budget-friendly choice over time.How does CuNi alloy wire compare to stainless steel?

CuNi offers better corrosion resistance in marine settings and higher electrical conductivity, though stainless steel is stronger for structural applications.Can we get custom CuNi alloy wire?

Totally! We can tweak the nickel content (like CuNi10 or CuNi44) or supply it as wire, strip, or ribbon to match your project’s needs.Is CuNi alloy wire environmentally friendly?

It’s recyclable, which aligns with sustainable practices, and its durability reduces the need for frequent replacements, cutting waste.