High-Quality CuNi Wire for Precision Electrical Applications

We’re proud to offer top-notch CuNi wire, a copper-nickel alloy that’s become a go-to for industries needing reliability and precision. This isn’t just any wire—it’s a game-changer for applications where performance can’t be compromised. Whether you’re working on electrical resistors, heating systems, or marine equipment, our CuNi wire delivers, and here’s why we think it’s a cut above the rest.

First off, CuNi wire is a champ when it comes to corrosion resistance. Thanks to the nickel content—anywhere from 10% in CuNi10 to 44% in CuNi44 —it stands up to harsh environments like seawater, making it a favorite for marine and offshore applications. We’ve seen it used in everything from ship wiring to desalting systems, and it just keeps performing.

Then there’s its thermal stability. Our CuNi wire can handle temperatures up to 400°C, and some grades even push to 500°C. That makes it perfect for heating cables, resistors, and thermocouples where consistent performance under heat is a must. Plus, its electrical resistivity is steady, so you get predictable results in precision applications like potentiometers or superconducting switches.

We also love how versatile this wire is. It’s ductile, so it’s easy to shape and weld, which saves time and hassle during manufacturing. Whether you need it as a thin wire, ribbon, or strip, we can customize it to fit your specs. From electronics to aerospace, our customers use CuNi wire for everything from motor controls to communication cables, and it’s no surprise why—it’s tough, reliable, and built to last.

Industry trends are leaning hard into materials that balance performance with sustainability, and CuNi wire fits the bill. It’s recyclable, which is a big win for eco-conscious projects, and its long service life means less maintenance and fewer replacements. Sure, it’s a bit pricier than some other alloys, but when you factor in its durability and low upkeep, it’s a smart investment.

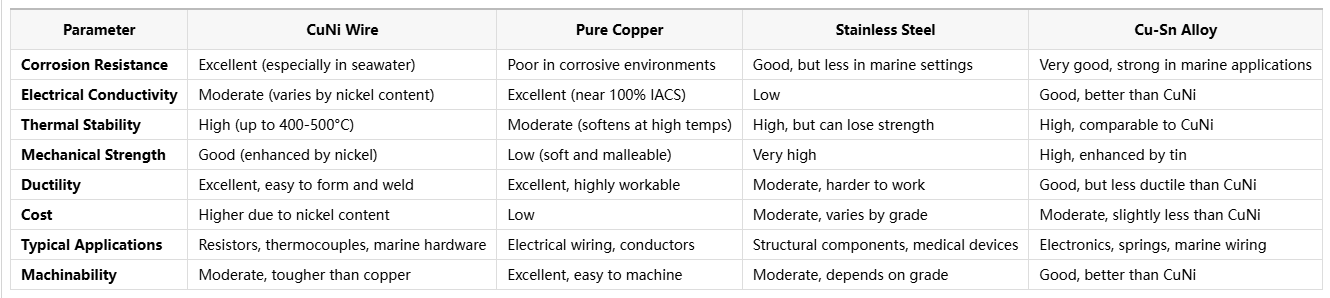

Compared to alternatives like pure copper or stainless steel, CuNi wire strikes a unique balance. Pure copper’s great for conductivity, but it can’t match CuNi’s corrosion resistance or strength in tough conditions. Stainless steel’s strong, but its lower conductivity limits its use in electrical applications. And while Cu-Sn alloys are solid contenders, CuNi often edges them out in marine environments and precision settings.

We’ve been in this game for years, and our CuNi wire is crafted with precision to meet standards like ISO 9001. Whether you’re building cutting-edge electronics or rugged marine systems, we’ve got the wire to make your project shine. Need a specific grade or size? Just let us know—we’re here to make it happen.

Comparison Parameters Table

Exceptional corrosion resistance in harsh environments

High thermal stability for elevated temperature applications

Consistent electrical resistivity for precision performance

Excellent ductility for easy forming and welding

Long service life with low maintenance requirements

Parameter:

Properties Material | Resistivity 200c μΩ.m | Max working temperature (℃) | Tensile strength (Mpa) | Melting point (℃) | Density (g/cm3) | TCR *10-6/℃ (20-600℃) | EMF vs Cu (μV/℃) (0-100℃) |

CuNi1 | 0.03 | 200 | 210 | 1085 | 8.9 | <100 | -8 |

CuNi2 | 0.05 | 200 | 220 | 1090 | 8.9 | <120 | -12 |

CuNi6 | 0.1 | 220 | 250 | 1095 | 8.9 | <60 | -18 |

CuNi8 | 0.12 | 250 | 270 | 1097 | 8.9 | <57 | -22 |

CuNi10 | 0.15 | 250 | 290 | 1100 | 8.9 | <50 | -25 |

CuNi14 | 0.2 | 300 | 310 | 1115 | 8.9 | <30 | -28 |

CuNi19 | 0.25 | 300 | 340 | 1135 | 8.9 | <25 | -32 |

CuNi23 | 0.3 | 300 | 350 | 1150 | 8.9 | <16 | -34 |

CuNi30 | 0.35 | 350 | 400 | 1170 | 8.9 | <10 | -37 |

0.4 | 350 | 400 | 1180 | 8.9 | 0 | -39 | |

CuNi44 | 0.5 | 400 | 420 | 1200 | 8.9 | <-6 | -43 |

Size Range | |

Wire | 0.08-7.5mm |

Ribbon | (0.05-0.35)*(0.5-6.0)mm |

Strip | (0.50-2.5)*(5-180)mm |

Rod | 8-50mm |

For more details, pls directly contact us.

About Us:

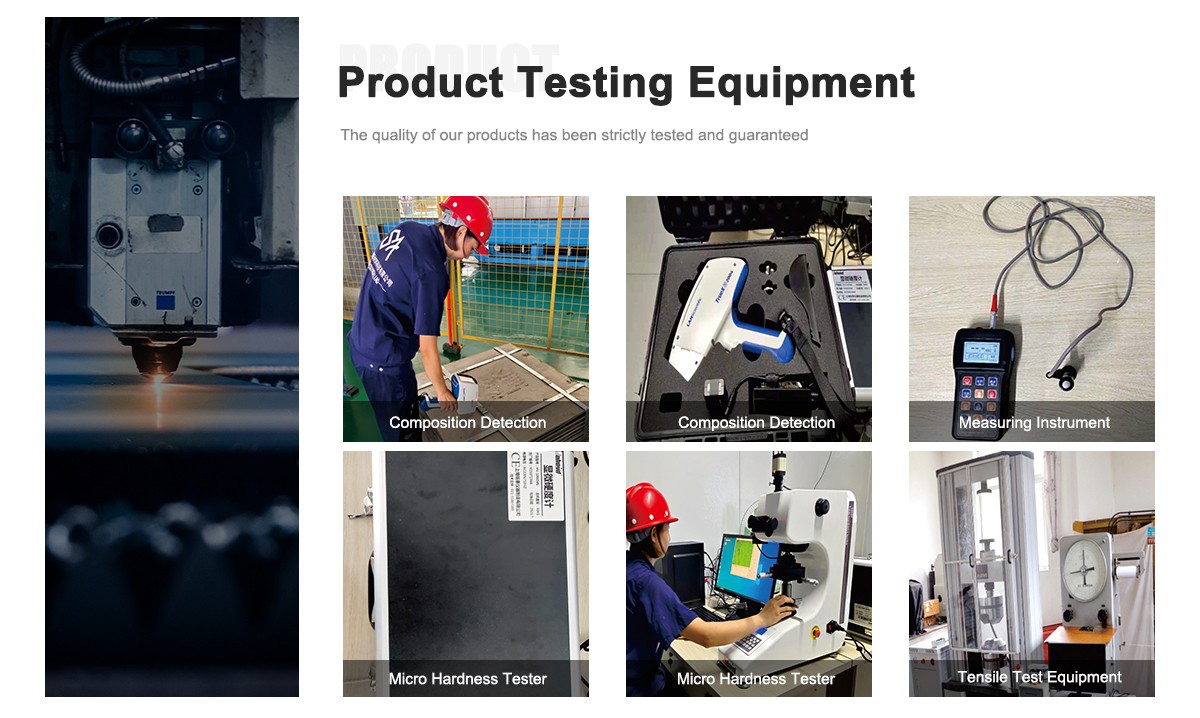

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs

What is CuNi wire made of?

CuNi wire is a copper-nickel alloy, typically with varying nickel content (e.g., 10% in CuNi10 or 44% in CuNi44), sometimes with small amounts of manganese or iron to enhance specific properties like corrosion resistance or strength.What are the main applications of CuNi wire?

It’s used in electrical resistors, heating cables, thermocouples, marine hardware, and precision components in industries like electronics, aerospace, and marine engineering.Why is CuNi wire corrosion-resistant?

The nickel content, along with additions like iron in alloys like CuNi10Fe, makes it highly resistant to seawater and other corrosive environments, ideal for marine and industrial uses.Can CuNi wire handle high temperatures?

Yes, it’s stable up to around 400°C (750°F) for most grades, with some like CuNi30Mn handling up to 500°C, making it great for heating and high-temperature environments.Is CuNi wire expensive compared to other alloys?

It’s pricier than stainless steel or aluminum due to copper and nickel costs, but its durability and performance often justify the investment for critical applications.How does CuNi wire compare to pure copper?

CuNi wire has lower electrical conductivity but offers better corrosion resistance and mechanical strength, making it suitable for harsher conditions where pure copper would fail.Is CuNi wire safe to use?

Generally, yes, it’s safe for most applications. However, prolonged exposure to nickel or copper dust in occupational settings requires proper ventilation and safety measures.Can CuNi wire be customized?

Absolutely, we can adjust nickel content (e.g., CuNi10, CuNi44) and forms (wire, ribbon, strip) to meet specific resistivity or mechanical needs for your project.