Hastelloy B-2 Bar: High-Strength Nickel-Molybdenum Alloy for Reducing Acid Resistance

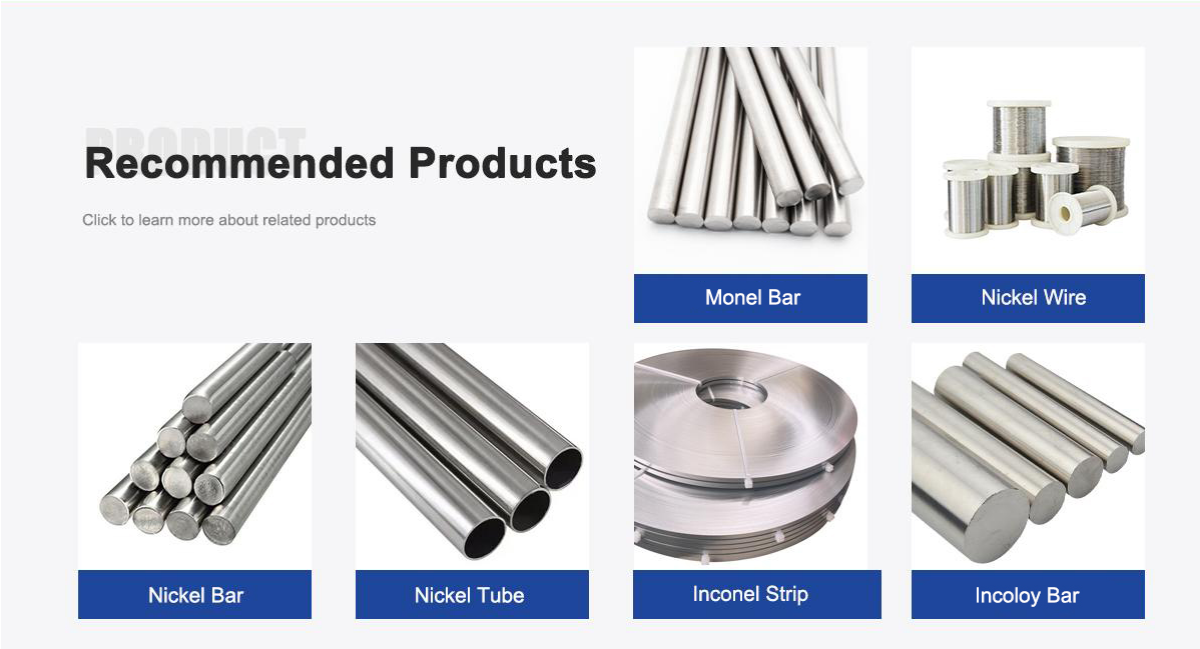

When industries operate in aggressive chemical environments, the selection of materials becomes critical to ensure safety, reliability, and longevity of equipment. One of the alloys that has become a trusted choice for reducing acid environments is Hastelloy B-2. In bar form, this nickel-molybdenum alloy delivers exceptional resistance to hydrochloric acid and other strong reducing agents, making it indispensable in chemical processing and related industries. At DLX, we specialize in supplying Hastelloy B-2 Bars that meet stringent global standards, providing customers with durable solutions for their most challenging applications.

For more details, pls directly contact us.

Hastelloy B-2 is primarily composed of nickel and molybdenum, with carefully balanced elements to maximize corrosion resistance in reducing conditions. Unlike alloys that excel in oxidizing environments, B-2 is tailored for reducing acids, especially hydrochloric acid in all concentrations and at all temperatures. This makes it one of the best-performing alloys in such applications.

In round or rectangular bar form, Hastelloy B-2 provides the raw material for critical components. These include reaction vessel parts, pumps, shafts, valves, fasteners, and fittings that are constantly exposed to reducing media. The stability of B-2 ensures long service life, reduced downtime, and safer operations.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

The versatility of Hastelloy B-2 Bar is evident in its wide range of industrial applications:

-

Chemical Processing: It is used in reactors, evaporators, heat exchangers, and transfer lines handling hydrochloric acid and other reducing agents.

-

Pharmaceuticals: Equipment used for drug production and sterilization requires resistance to strong chemical cleaning agents, which Hastelloy B-2 provides.

-

Marine Industry: Though not as chloride-resistant as other Hastelloy grades, it is used in certain marine applications where reducing agents are present.

-

Pollution Control: Waste treatment plants use B-2 components to withstand aggressive acidic conditions.

-

Energy Sector: Some refining and power generation processes involve reducing environments where B-2 is a reliable material.

-

Pulp and Paper Industry: Acid-based bleaching and chemical recovery processes benefit from its stability in reducing media.

Every one of these applications involves environments where standard stainless steels or less robust alloys would fail prematurely. DLX Hastelloy B-2 Bars ensure maximum reliability and safety.

The demand for Hastelloy B-2 is steadily increasing worldwide, particularly in regions with expanding chemical and pharmaceutical sectors. Several trends are driving this growth:

-

Chemical Industry Expansion: With rising global demand for chemicals, plants require reliable materials for processing aggressive acids.

-

Pharmaceutical Growth: Stringent production standards demand alloys that resist strong cleaning agents and reduce contamination risks.

-

Environmental Regulations: Stricter rules on waste management and pollution control are pushing industries to adopt alloys like B-2 that provide longer equipment lifespans.

-

Cost-Efficiency in Operations: Industries are shifting focus toward life-cycle costs, where premium alloys like B-2 reduce downtime and maintenance.

-

Emerging Markets: Rapid industrialization in Asia and the Middle East is creating new opportunities for high-performance alloys.

At DLX, we closely monitor these industry dynamics to ensure our customers always have access to the right materials at the right time.

Comparison Table: Hastelloy B-2 vs Common Alloys

| Property | Hastelloy B-2 Bar | Stainless Steel 316L | Hastelloy C-4 Bar |

|---|---|---|---|

| Base Material | Nickel-Molybdenum | Iron-Nickel-Chromium | Nickel-Chromium-Molybdenum |

| Corrosion Resistance | Excellent in reducing acids | Good in mild conditions | Excellent in oxidizing acids |

| Hydrochloric Acid Resistance | Outstanding at all concentrations | Limited | Moderate |

| Oxidizing Media Resistance | Limited | Moderate | Excellent |

| Temperature Performance | High, stable up to ~425°C | Up to ~870°C | Up to ~1100°C |

| Weldability | Good | Good | Excellent |

| Seawater Resistance | Moderate | Limited | Excellent |

| Typical Applications | Chemical plants, pharmaceuticals, pollution control | Food, water, architecture | Chemical, aerospace, marine |

| Cost Level | Higher | Lower | Higher |

Choosing the correct material is only part of the challenge; working with a reliable supplier is equally critical. DLX stands out as a trusted partner for industries worldwide by offering:

-

Strict Quality Control: Every Hastelloy B-2 Bar undergoes chemical composition analysis, mechanical property testing, and microstructure verification.

-

Customization: We offer bars in custom sizes and shapes to meet specific application requirements.

-

Global Supply Chain: With efficient logistics, we deliver products reliably to customers across different regions.

-

Technical Expertise: Our engineers provide guidance on fabrication, welding, and application to maximize performance.

-

Value-Oriented Service: While Hastelloy B-2 is a premium alloy, DLX ensures competitive pricing without sacrificing quality.

Stainless steels, such as 316L, are often used in less aggressive conditions due to their lower cost. However, they cannot handle hydrochloric acid effectively. In contrast, Hastelloy B-2 excels in this environment but has limited resistance to oxidizing agents. Alloys like Hastelloy C-4 perform better in oxidizing conditions but do not match B-2’s resistance in reducing acids.

By offering Hastelloy B-2 alongside other nickel alloys, DLX helps customers select the right material for each specific environment. This ensures cost-effective and long-term performance.

Global demand for Hastelloy B-2 is expected to rise significantly in the coming years. Industries driving this growth include:

-

Asia-Pacific Chemical Sector: Expansion of chemical manufacturing and processing facilities.

-

European Pharmaceutical Industry: Increasing demand for sterilization-resistant alloys.

-

Middle Eastern Energy Sector: Growth in refining and specialized energy projects requiring high-performance alloys.

-

North America Pollution Control: Stricter environmental standards requiring durable materials for waste treatment.

DLX is strategically positioned to support this global demand with a robust supply network and a customer-focused approach.

Conclusion

Hastelloy B-2 Bar is a high-strength nickel-molybdenum alloy engineered for exceptional resistance to reducing acids, particularly hydrochloric acid. Its stability, durability, and reliability make it indispensable in chemical processing, pharmaceuticals, and related industries.

At DLX, we supply Hastelloy B-2 Bars with strict adherence to international standards, backed by technical expertise and global logistics. Our customers know they can rely on us for consistent quality, tailored solutions, and timely delivery.

As industries worldwide continue to demand better materials for challenging environments, DLX remains committed to providing Hastelloy B-2 Bars that help customers achieve safe, efficient, and cost-effective operations.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is Hastelloy B-2 Bar made of?

A1: It is a nickel-molybdenum alloy designed to resist hydrochloric acid and other strong reducing agents.

Q2: What industries commonly use Hastelloy B-2 Bar?

A2: It is widely used in chemical processing, pharmaceuticals, marine engineering, energy, and pollution control.

Q3: How does Hastelloy B-2 Bar perform in hydrochloric acid environments?

A3: It offers outstanding resistance to hydrochloric acid in all concentrations and at all temperatures.

Q4: Can Hastelloy B-2 Bar resist oxidizing media?

A4: It is less resistant in oxidizing environments, so it is best suited for reducing conditions.

Q5: Is Hastelloy B-2 Bar easy to fabricate and weld?

A5: Yes, it has good weldability and can be fabricated using conventional techniques when proper guidelines are followed.

Q6: How does Hastelloy B-2 Bar compare to stainless steels?

A6: It performs far better in reducing acids but has a higher cost compared to stainless steel.

Q7: What standards does DLX follow for Hastelloy B-2 Bar?

A7: DLX ensures compliance with ASTM standards and conducts rigorous quality testing for every bar supplied.

Q8: Why should industries choose DLX as their supplier?

A8: DLX provides consistent quality, custom dimensions, technical expertise, and reliable global delivery.