Hastelloy C276 Bar: High-Performance Nickel Alloy for Corrosion Resistance

At DLX, we’re all about delivering top-tier solutions for industries that demand the best. Our Hastelloy C276 Bar is a standout product, crafted to tackle the toughest environments with unmatched corrosion resistance and durability. Let’s dive into what makes this high-performance nickel alloy a game-changer, explore its applications, industry trends, and why DLX is your go-to supplier.

For more details, pls directly contact us.

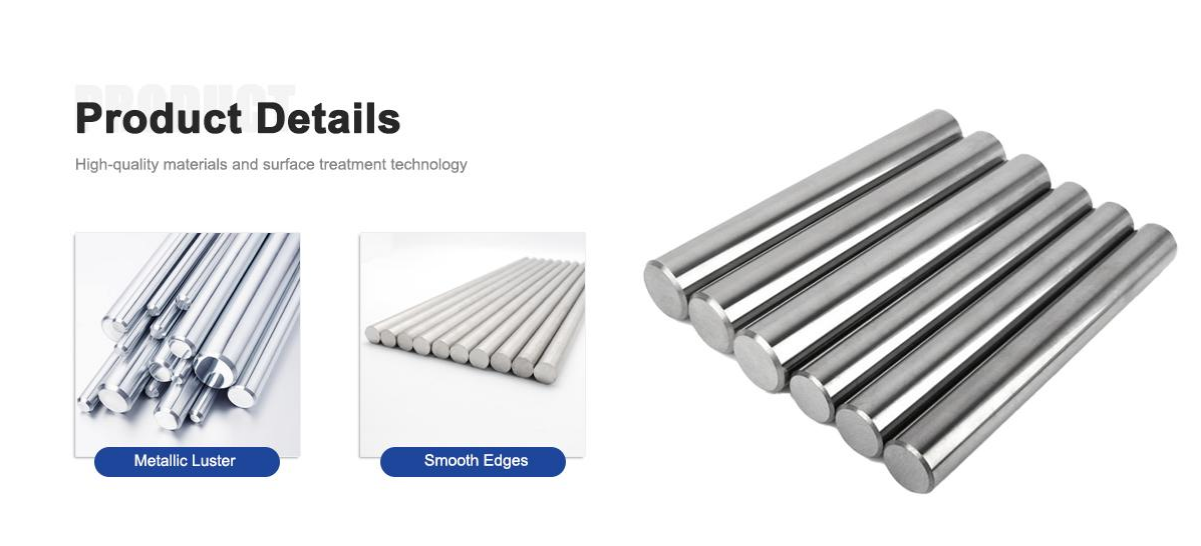

Our Hastelloy C276 Bar is a nickel-chromium-molybdenum alloy with a touch of tungsten, engineered for exceptional performance. Its chemical makeup—roughly 57% nickel, 15-17% molybdenum, 14.5-16.5% chromium, and 3-4.5% tungsten—gives it incredible resistance to corrosion in both oxidizing and reducing environments. This alloy (UNS N10276) shines where others fail, standing up to harsh chemicals like hydrochloric acid, sulfuric acid, and chlorine gas. It’s also immune to chloride-induced stress corrosion cracking, pitting, and crevice corrosion, making it a reliable choice for extreme conditions.

What sets it apart? Its low carbon content (max 0.01%) prevents carbide precipitation during welding, so it stays corrosion-resistant even in as-welded structures. With a melting point of 2415-2500°F (1323-1371°C) and the ability to perform at temperatures up to 1900°F (1037°C), it’s built for high-temperature stability. Whether you’re dealing with hot acids, seawater, or aggressive gases, our Hastelloy C276 Bar delivers unmatched strength and longevity.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Our Hastelloy C276 Bar is a workhorse across multiple industries, thanks to its versatility and durability. Here’s where it shines:

-

Chemical Processing: From reactors to heat exchangers, our bars are used in equipment handling corrosive acids like sulfuric, hydrochloric, and nitric. They’re perfect for distillation columns, piping, and valves in plants dealing with aggressive chemicals.

-

Pollution Control: Flue gas desulfurization systems rely on Hastelloy C276 for scrubbers, ducts, and stack liners, where it resists sulfur compounds and acidic gases.

-

Aerospace: High-temperature and corrosive environments in jet engines and turbine components demand materials like our C276 bars for their strength and stability.

-

Marine Engineering: Seawater and brine solutions are no match for this alloy, making it ideal for offshore platforms, ship components, and desalination plants.

-

Pharmaceuticals and Food Processing: Its resistance to organic and inorganic chlorides ensures clean, reliable performance in equipment like mixers and reactors.

-

Nuclear and Energy: Used in nuclear fuel reprocessing and sour gas environments, our bars withstand radioactive and high-pressure conditions.

This alloy’s ability to handle such diverse applications makes it a go-to for engineers looking for reliability in extreme settings.

Industry Trends Driving Demand

The demand for Hastelloy C276 Bar is on the rise, fueled by trends across key industries. In chemical processing, stricter environmental regulations are pushing companies to invest in materials that can handle aggressive chemicals without frequent replacements. The global shift toward sustainable energy has increased the need for pollution control systems, where C276’s resistance to acidic gases is critical. The aerospace sector is seeing growth in high-performance alloys due to advancements in jet engine technology, which requires materials that can endure extreme heat and stress.

Marine industries are also expanding, with offshore wind farms and desalination plants driving demand for corrosion-resistant materials like Hastelloy C276. Meanwhile, the pharmaceutical industry is prioritizing high-purity materials to meet stringent safety standards, further boosting the alloy’s popularity. According to recent market insights, the nickel alloy market is projected to grow steadily through 2030, with Hastelloy C276 remaining a top choice due to its unmatched performance in corrosive environments.

Another trend is the focus on sustainability. Industries are leaning toward materials that offer longer lifespans to reduce waste and maintenance costs. Our Hastelloy C276 Bar fits the bill, delivering durability that minimizes replacements and downtime. Additionally, advancements in machining and welding techniques are making it easier to work with high-performance alloys, further expanding their use in complex applications.

Comparison Table: Hastelloy C276 vs. C22, C-4, B-2

|

Parameter |

Hastelloy C276 |

Hastelloy C22 |

Hastelloy C-4 |

Hastelloy B-2 |

|---|---|---|---|---|

|

UNS Number |

N10276 |

N06022 |

N06455 |

N10665 |

|

Nickel Content |

~57% |

~56% |

~65% |

~68% |

|

Molybdenum Content |

15-17% |

12.5-14.5% |

14-18% |

26-30% |

|

Chromium Content |

14.5-16.5% |

20-22.5% |

14-18% |

1% max |

|

Tungsten Content |

3-4.5% |

2.5-3.5% |

None |

None |

|

Corrosion Resistance |

Excellent in oxidizing/reducing environments |

Superior in oxidizing media |

Good in high-temperature acids |

Best in reducing acids (e.g., HCl) |

|

Temperature Range |

Up to 1900°F (1037°C) |

Up to 1250°F (676°C) |

Up to 1900°F (1037°C) |

Up to 1800°F (982°C) |

|

Weldability |

Excellent, no grain boundary issues |

Very good, slightly better formability |

Good, stable at high temperatures |

Good, but sensitive to oxidizing media |

|

Key Applications |

Chemical processing, pollution control |

Marine, chemical reactors |

Aerospace, chemical equipment |

Acid production, chemical processing |

|

Density (g/cm³) |

8.89 |

8.69 |

8.64 |

9.22 |

|

Melting Point |

2415-2500°F (1323-1371°C) |

2475-2550°F (1357-1399°C) |

2435-2500°F (1335-1371°C) |

2430-2500°F (1332-1371°C) |

At DLX, we’ve spent over two decades perfecting our craft, and our Hastelloy C276 Bar reflects that expertise. Here’s why we’re the supplier you can trust:

-

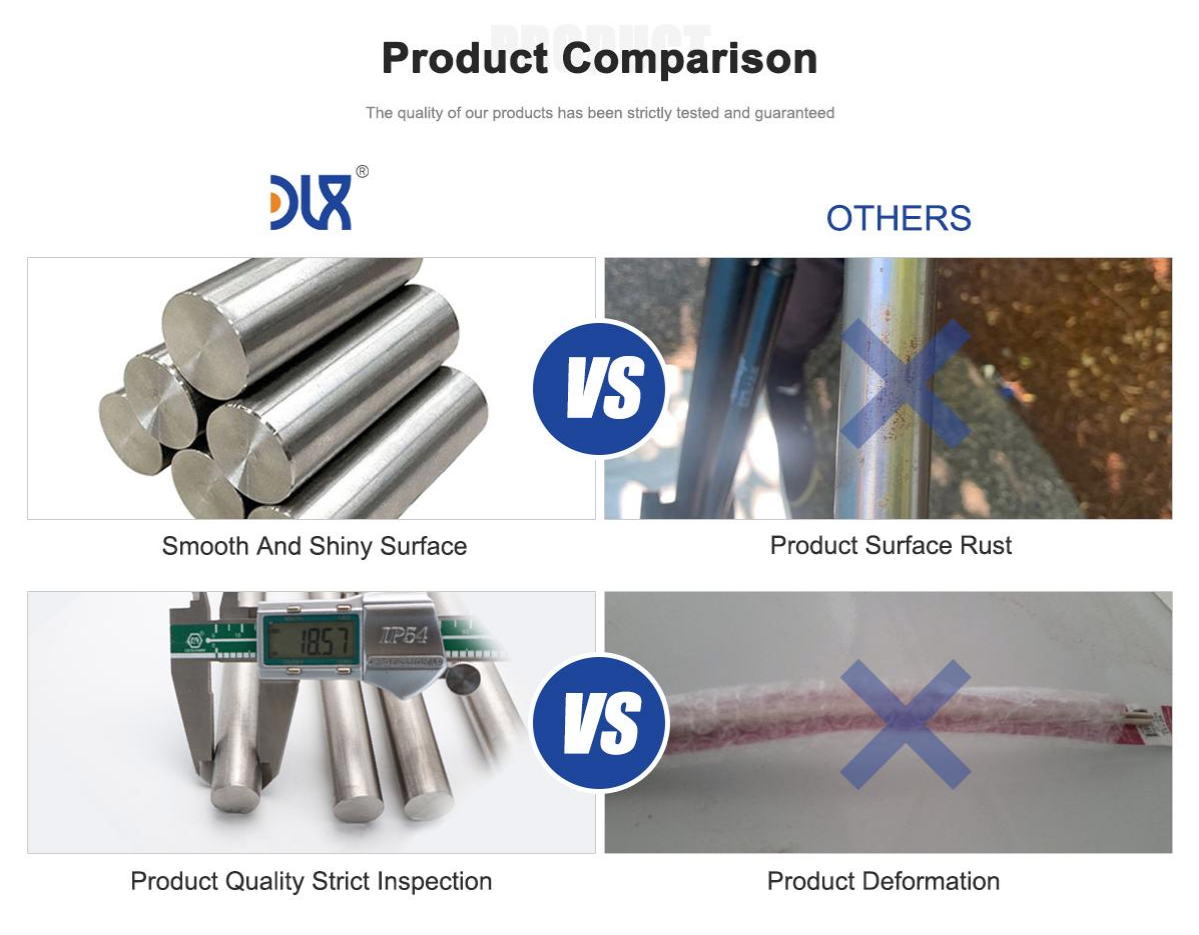

Uncompromising Quality: Every bar undergoes rigorous testing, including spectral analysis and checks for size, strength, and resistivity, ensuring a product pass rate above 99%. Our ISO 9001 certification backs our commitment to excellence.

-

Extensive Inventory: We stock a wide range of sizes and forms, from round bars to hex and flat bars, ready for fast delivery to keep your projects on track.

-

Customization Options: Need a specific size or shape? Our advanced manufacturing capabilities let us tailor Hastelloy C276 Bars to your exact specifications.

-

Technical Expertise: Our team doesn’t just sell materials—we help you choose the right alloy for your operating conditions, ensuring optimal performance.

-

Reliable Supply Chain: We’ve built long-term relationships with trusted raw material suppliers, guaranteeing consistent quality and availability.

-

Global Reach: With efficient shipping options by air, sea, or express, we deliver worldwide, ensuring your materials arrive on time, every time.

Unlike others, we prioritize customer needs, offering technical support and competitive pricing without cutting corners on quality. Our focus on research and development keeps us ahead of the curve, delivering alloys that meet the evolving demands of modern industries.

Machining and Fabrication Tips

Working with Hastelloy C276 Bar requires some know-how, but it’s manageable with the right approach. This alloy is considered moderately difficult to machine due to its work-hardening nature, which generates high heat during cutting. To get the best results, use rigid machines with minimal tool overhang and keep tools sharp—dull tools can cause issues. For drilling, ensure adequate depth of cut to avoid work-hardened zones. When welding, use fillers like ERNiCrMo-4 or ERNiCrMo-10 for optimal corrosion resistance, and skip post-weld heat treatment unless your application demands it. Our team at DLX can provide detailed guidance to ensure your fabrication process is smooth and efficient.

Comparing Hastelloy C276 to Other Alloys

While our comparison table above highlights key differences, let’s break it down further. Compared to Hastelloy C22, our C276 Bar offers better resistance to reducing environments due to its higher molybdenum content, though C22 excels in oxidizing media. Hastelloy C-4 is great for high-temperature stability but lacks tungsten, making it less versatile in chloride-rich settings. Hastelloy B-2 is a champ in reducing acids like hydrochloric but struggles in oxidizing conditions. For projects needing broad corrosion resistance across mixed environments, our C276 Bar is often the best all-around choice.

When pitted against stainless steels like 316L or 254SMO, Hastelloy C276 outperforms in hydrochloric acid concentrations above 5%, where stainless steels falter. It also beats lower-molybdenum alloys like Inconel 625 in highly corrosive settings, offering superior pitting and crevice corrosion resistance. This makes our C276 Bar a premium choice for applications where failure isn’t an option.

Why Invest in Hastelloy C276 Bar?

Choosing our Hastelloy C276 Bar means investing in reliability, longevity, and performance. Its ability to withstand extreme corrosion, high temperatures, and mechanical stress ensures your equipment lasts longer, reducing downtime and maintenance costs. Whether you’re building chemical reactors, marine components, or aerospace parts, this alloy delivers peace of mind in the harshest conditions.

At DLX, we’re not just selling a product—we’re providing a solution backed by years of expertise and a passion for quality. Our Hastelloy C276 Bar is designed to meet the toughest industry standards, from ASTM B574 to stringent chemical composition requirements. With our extensive inventory, fast delivery, and tailored support, we make it easy to get the materials you need, when you need them.

Get Started with DLX

Ready to power your project with Hastelloy C276 Bar? Contact us today for a free quote, technical data sheets, or expert advice on selecting the right alloy. At DLX, we’re committed to helping you succeed with materials that stand up to the toughest challenges. Let’s build something durable, reliable, and high-performing together.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Hastelloy C276 Bar made of?

It’s a nickel-chromium-molybdenum alloy with tungsten, designed for top-notch corrosion resistance and strength. -

What industries use Hastelloy C276 Bar?

Chemical processing, aerospace, marine, pollution control, and pharmaceutical industries rely on it for harsh environments. -

How does Hastelloy C276 resist corrosion?

Its high molybdenum and chromium content protects against pitting, crevice corrosion, and stress corrosion cracking in acidic and chloride-rich settings. -

Can Hastelloy C276 Bar handle high temperatures?

Yes, it performs well up to 1900°F (1037°C) in oxidizing environments, maintaining strength and stability. -

Is Hastelloy C276 Bar weldable?

Absolutely, it’s easy to weld without forming grain boundary precipitates, making it ideal for as-welded applications. -

What are typical applications for Hastelloy C276 Bar?

It’s used in heat exchangers, reactors, flue gas desulfurization systems, and components exposed to seawater or acids. -

How does Hastelloy C276 compare to other alloys?

It outperforms many stainless steels and lower-molybdenum alloys in corrosive environments, especially with chlorides. -

What forms does DLX offer for Hastelloy C276?

We provide bars, rods, sheets, plates, tubes, and custom shapes to meet your project needs.