UNS N06455 Hastelloy C-4 Round Bar for Chemical and Aerospace Industries

Materials play a crucial role in industries where failure is not an option. For equipment operating in environments filled with aggressive chemicals or exposed to extreme heat, the right alloy can mean the difference between uninterrupted operation and costly downtime. UNS N06455 Hastelloy C-4 Round Bar is one such material that has proven to be a game-changer for both chemical and aerospace industries. At DLX, we focus on delivering this high-performance alloy with the quality, consistency, and reliability our customers demand.

For more details, pls directly contact us.

Hastelloy C-4, designated as UNS N06455, is a nickel-chromium-molybdenum alloy developed to withstand the most aggressive environments. What sets it apart from many other alloys is its exceptional resistance to strong oxidizers such as ferric and cupric chlorides, chlorine, and hot contaminated mineral acids. Even more importantly, it maintains structural integrity at elevated temperatures where many alloys weaken due to grain-boundary precipitates.

In round bar form, Hastelloy C-4 becomes highly versatile. These bars are used to machine components like pump shafts, valves, fittings, fasteners, and aerospace hardware. With its combination of corrosion resistance and high-temperature strength, UNS N06455 Hastelloy C-4 Round Bar has become a preferred material for demanding industries worldwide.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

The adaptability of Hastelloy C-4 Round Bar makes it valuable across a wide range of industries:

-

Chemical Processing: Equipment such as heat exchangers, reactors, evaporators, and transfer piping requires resistance to aggressive acids and oxidizing environments. C-4 delivers durability that stainless steel cannot match.

-

Aerospace: Components in aerospace applications are subjected to both high temperatures and corrosive atmospheres. C-4’s stability ensures reliable performance in engines, exhaust systems, and high-stress hardware.

-

Marine Engineering: Long-term resistance to chloride-induced corrosion makes it ideal for shafts, pumps, and fasteners exposed to seawater.

-

Pollution Control: Flue gas scrubbers and waste treatment facilities use C-4 bars to withstand acidic and oxidizing conditions.

-

Pharmaceuticals: High-purity processes that require aggressive sterilization benefit from C-4’s resistance to strong cleaning agents.

-

Pulp and Paper Industry: Chlorine-based bleaching operations can quickly corrode conventional alloys, but C-4 provides long-lasting durability.

Every application requires reliability, and that is where DLX Hastelloy C-4 Round Bars make a real difference. Customers can count on long-term performance and lower maintenance costs, leading to significant savings over the life of their equipment.

Demand for alloys like Hastelloy C-4 is growing worldwide, driven by several industry trends:

-

Expansion of Chemical Processing Plants: With rising global demand for chemicals, manufacturers are under pressure to operate continuously. Materials like C-4 reduce downtime by resisting aggressive chemical attack.

-

Aerospace Growth: As aerospace technology advances, materials must handle more extreme environments. C-4 provides stability at high temperatures and in corrosive atmospheres.

-

Stricter Environmental Standards: Pollution control systems are expanding globally, requiring alloys that withstand acidic exhaust and scrubbing systems.

-

Marine Development: Offshore oil, gas, and desalination projects need alloys that provide long-term seawater resistance.

-

Life-Cycle Cost Focus: Companies increasingly recognize the value of investing in alloys like C-4 that reduce maintenance and extend equipment lifespan.

At DLX, we see these trends as opportunities to deliver more value to our customers. By staying ahead of industry needs, we ensure that our supply of Hastelloy C-4 Round Bars aligns with global growth sectors.

Comparison Table: Hastelloy C-4 vs Common Alloys

| Property | UNS N06455 Hastelloy C-4 Round Bar | Stainless Steel 316L | Alloy 625 Round Bar |

|---|---|---|---|

| Base Material | Nickel-Chromium-Molybdenum | Iron-Nickel-Chromium | Nickel-Chromium-Molybdenum |

| Corrosion Resistance | Excellent in oxidizing media | Good in mild conditions | Excellent, less stable under thermal cycling |

| Chloride Resistance | Superior resistance to pitting/crevice | Moderate | High |

| Temperature Performance | Up to ~1100°C | Up to ~870°C | Up to ~1093°C |

| Weldability | Excellent | Good | Excellent |

| Seawater Resistance | Long-term durability | Limited | Excellent |

| Structural Stability | Exceptional at elevated temperatures | Moderate | Good |

| Typical Applications | Chemical plants, aerospace, marine, pollution control | Food, water, architecture | Aerospace, chemical processing |

| Cost Level | Higher | Lower | High |

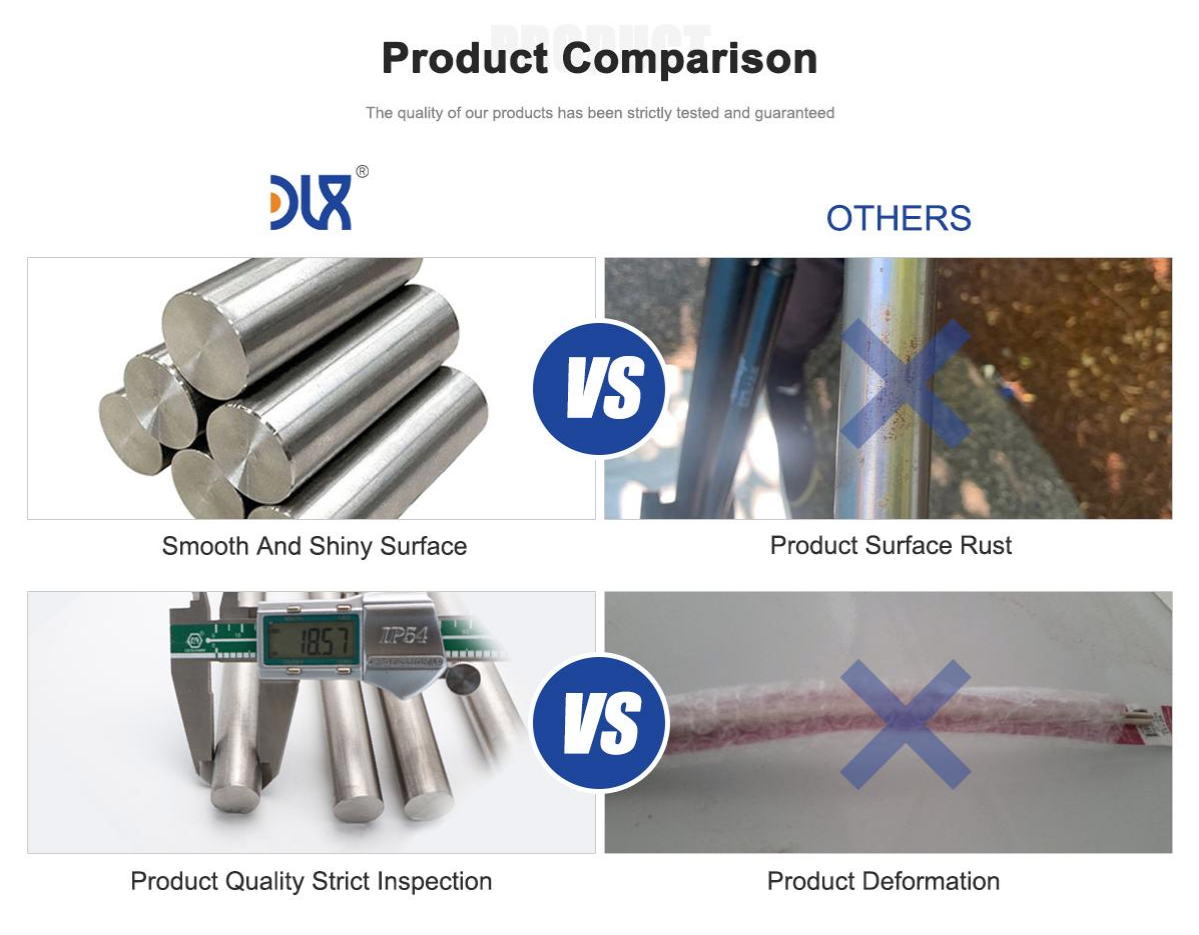

The choice of supplier is just as critical as the choice of material. At DLX, we go beyond simply providing Hastelloy C-4 Round Bars—we deliver complete solutions:

-

Uncompromising Quality: Every round bar is tested for chemical composition, strength, and microstructure to ensure it meets international standards.

-

Tailored Services: From cut-to-size bars to custom machining, DLX provides flexibility to match customer requirements.

-

Global Logistics: Our reliable distribution network ensures timely deliveries to customers worldwide.

-

Expert Technical Support: We assist with application guidance, welding procedures, and best practices to maximize material performance.

-

Competitive Value: While Hastelloy C-4 is a premium material, DLX ensures competitive pricing without compromising quality.

By working with DLX, customers gain more than just a supplier—they gain a partner committed to their long-term success.

While stainless steel is widely available and cost-effective, it cannot withstand highly oxidizing environments or maintain stability at high temperatures. Alloy 625 offers excellent corrosion resistance but is less stable than C-4 during thermal cycling. This makes UNS N06455 Hastelloy C-4 Round Bar the optimal choice for industries requiring both corrosion resistance and structural reliability in high-temperature environments.

DLX ensures customers receive this superior material in the right form, dimensions, and specifications, ready for the most demanding applications.

The future for UNS N06455 Hastelloy C-4 Round Bars looks strong, with continued demand across multiple industries. DLX is prepared to support customers in:

-

Asia-Pacific: Driven by rapid industrialization and chemical plant expansion.

-

Europe: Focused on environmental compliance and aerospace growth.

-

Middle East: With desalination and offshore projects requiring seawater-resistant materials.

-

North America: Where energy, aerospace, and chemical sectors continue to expand.

By maintaining a strong supply chain, DLX ensures customers can rely on us for timely, consistent delivery of Hastelloy C-4 Round Bars.

Conclusion

UNS N06455 Hastelloy C-4 Round Bar is a durable, high-performance alloy designed to thrive in environments where ordinary materials fail. Its resistance to oxidizing agents, chloride-induced corrosion, and high-temperature instability makes it indispensable in both chemical and aerospace industries.

At DLX, we deliver more than just Hastelloy C-4 Round Bars—we deliver reliability, expertise, and global support. With our strict quality control, tailored solutions, and customer-first approach, DLX stands out as a trusted partner for industries that demand the best.

As global industries continue to evolve and push the limits of materials, DLX is committed to ensuring that Hastelloy C-4 Round Bar remains a reliable solution for the most challenging environments.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is UNS N06455 Hastelloy C-4 Round Bar?

A1: It is a nickel-chromium-molybdenum alloy round bar with excellent resistance to strong oxidizing agents and high-temperature environments.

Q2: What are the main industries that use Hastelloy C-4 Round Bar?

A2: It is widely used in chemical processing, aerospace, marine engineering, pharmaceuticals, and pollution control.

Q3: How does Hastelloy C-4 Round Bar perform under high temperatures?

A3: It maintains structural stability and corrosion resistance up to about 1100°C, even during thermal cycling.

Q4: Is UNS N06455 Hastelloy C-4 Round Bar weldable?

A4: Yes, it offers excellent weldability and fabricability with standard techniques.

Q5: How does Hastelloy C-4 Round Bar resist chlorides?

A5: It provides strong resistance against pitting, crevice corrosion, and stress corrosion cracking in chloride-rich environments.

Q6: What makes Hastelloy C-4 different from other nickel alloys?

A6: Its superior resistance to grain-boundary precipitates during high-temperature exposure ensures stability and strength.

Q7: What standards does DLX follow for Hastelloy C-4 Round Bar supply?

A7: DLX ensures strict compliance with ASTM and international quality standards through rigorous testing.

Q8: Why should industries choose DLX as their supplier?

A8: DLX provides consistent quality, customized sizes, technical expertise, and global delivery to meet demanding industrial requirements.