Hastelloy C-4 Bar: Durable Nickel-Chromium-Molybdenum Alloy for High-Temperature Use

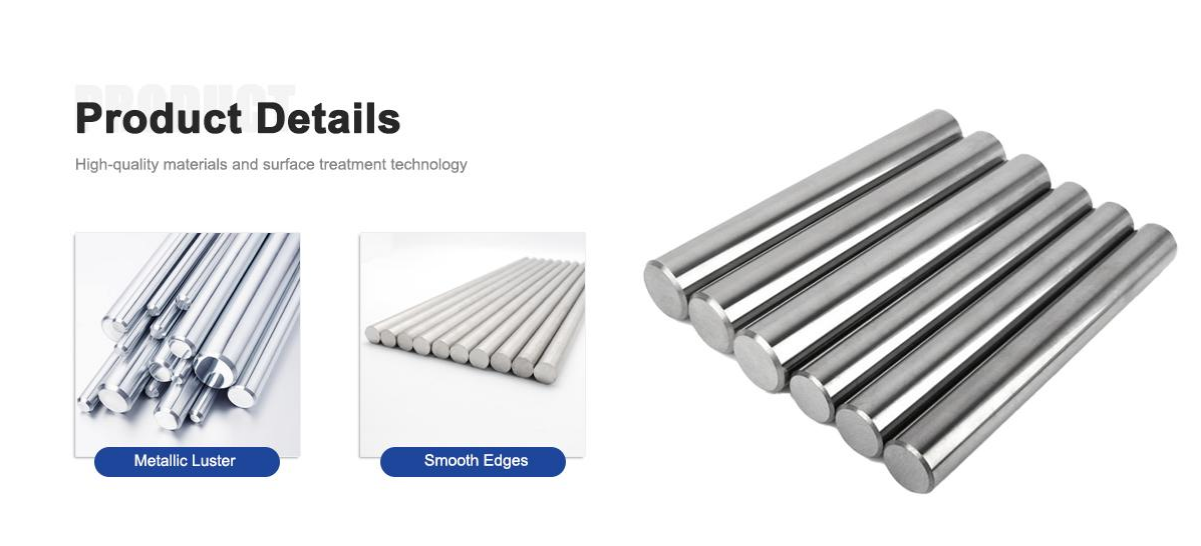

In industries where extreme temperatures and highly corrosive environments are a daily reality, material selection determines not only the efficiency of operations but also the safety and longevity of critical equipment. Hastelloy C-4 Bar, a premium nickel-chromium-molybdenum alloy, was developed specifically to handle these conditions. At DLX, we have built our reputation around supplying high-performance alloys like Hastelloy C-4 that meet global standards and deliver consistent, reliable results across demanding applications.

For more details, pls directly contact us.

Hastelloy C-4 is unique among the nickel-chromium-molybdenum family because of its exceptional structural stability at elevated temperatures. While many alloys suffer from grain-boundary precipitation when exposed to high heat, C-4 resists these microstructural changes, maintaining its toughness and corrosion resistance. Its typical composition includes about 65% nickel, 15–16% chromium, and 15–17% molybdenum, with controlled amounts of iron and other elements to enhance performance.

In bar form, Hastelloy C-4 is particularly valuable. It provides raw stock for machining into reactor parts, pump shafts, fasteners, marine hardware, and custom components that must not fail under prolonged exposure to chemicals or heat. When industries rely on DLX for Hastelloy C-4 Bars, they receive material that complies with ASTM standards, is tested for quality, and is prepared for the most critical applications.

Specification

|

item |

HC-276 |

C-22 |

C-4 |

B2 |

B3 |

N |

|

C |

≤0.01 |

≤0.015 |

≤0.015 |

≤0.02 |

≤0.01 |

0.04-0.08 |

|

Mn |

≤1 |

≤0.5 |

≤1 |

≤1 |

≤3 |

≤1 |

|

Fe |

4-7 |

2-6 |

≤3 |

≤2 |

≤1.5 |

≤5 |

|

P |

≤0.04 |

≤0.02 |

≤0.04 |

≤0.04 |

-- |

≤0.015 |

|

S |

≤0.03 |

≤0.02 |

≤0.03 |

≤0.03 |

-- |

≤0.02 |

|

Si |

≤0.08 |

≤0.08 |

≤0.08 |

≤0.1 |

≤0.1 |

≤1 |

|

Ni |

rest |

rest |

rest |

rest |

≤65 |

rest |

|

Co |

≤2.5 |

≤2.5 |

≤2 |

≤1 |

≤3 |

≤0.2 |

|

Ti+Cu |

-- |

-- |

≤0.7 |

-- |

≤0.4 |

≤0.35 |

|

Al+Ti |

-- |

-- |

-- |

-- |

≤0.5 |

≤0.5 |

|

Cr |

14.5-16.5 |

20-22.5 |

14-18 |

≤1 |

≤1.5 |

6-8 |

|

Mo |

15-17 |

12.5-14.5 |

14-17 |

26-30 |

≤28.5 |

15-18 |

|

B |

-- |

-- |

-- |

-- |

-- |

≤0.01 |

|

W |

3-4.5 |

2.5-3.5 |

-- |

-- |

≤3 |

≤0.5 |

|

V |

≤0.35 |

≤0.35 |

-- |

0.2-0.4 |

-- |

≤0.5 |

|

Shape |

Size (mm) |

|

Wire |

0.5-7.5 |

|

Rod/Bar |

8.0-200 |

|

Strip |

(0.5-2.5)*(5-180) |

|

Tube/Pipe |

Custom made |

|

Sheet/Plate |

Custom made |

For more details, pls directly contact us.

Hastelloy C-4 Bar is used across multiple industries where both heat and corrosive conditions are present:

-

Chemical Processing: Equipment such as heat exchangers, reaction vessels, and transfer piping face constant attack from aggressive chemicals. Hastelloy C-4 provides durability in oxidizing agents and mixed chemical processes.

-

Marine Engineering: Saltwater is notorious for destroying metals over time. C-4 rods and bars are used for shafts, fasteners, and pump components that resist chloride-induced corrosion.

-

Pollution Control: Waste incinerators and flue gas scrubbers benefit from C-4’s ability to resist acidic condensates and high-temperature gases.

-

Pulp and Paper Industry: Bleaching operations use chlorine-based chemicals that can quickly corrode ordinary alloys. Hastelloy C-4 offers long-lasting resistance.

-

Pharmaceutical Equipment: Sterilization and cleaning processes involve strong oxidizers, where C-4 bars provide reliability and prevent contamination.

-

Energy Sector: Power plants and geothermal systems often expose materials to both heat and corrosive media, where C-4 excels.

Every one of these applications has one thing in common: the need for uninterrupted operation. Failures caused by material breakdown can result in safety hazards, costly downtime, and expensive repairs. DLX Hastelloy C-4 Bars help minimize these risks by delivering dependable performance in the most aggressive conditions.

The global market for high-performance alloys like Hastelloy C-4 is expanding. Several trends are fueling this growth:

-

Rising Chemical Production: As demand for chemicals increases, processing plants are under pressure to operate continuously with minimal downtime. This requires alloys that can survive in aggressive chemical environments.

-

Stricter Environmental Standards: Pollution control technologies are expanding worldwide, requiring materials that resist corrosive flue gases and acidic scrubbing solutions.

-

Marine Infrastructure Growth: With increasing investments in desalination and offshore oil projects, alloys like C-4 are in higher demand for their seawater durability.

-

Focus on Life-Cycle Costs: Companies increasingly recognize that the initial higher investment in premium alloys pays off through longer equipment life and lower maintenance.

-

Global Energy Expansion: Geothermal and alternative energy sectors need materials that perform in both corrosive and high-temperature conditions, driving adoption of C-4.

At DLX, we track these industry trends closely, positioning ourselves as a trusted supplier for customers who need reliable access to Hastelloy C-4 Bars worldwide.

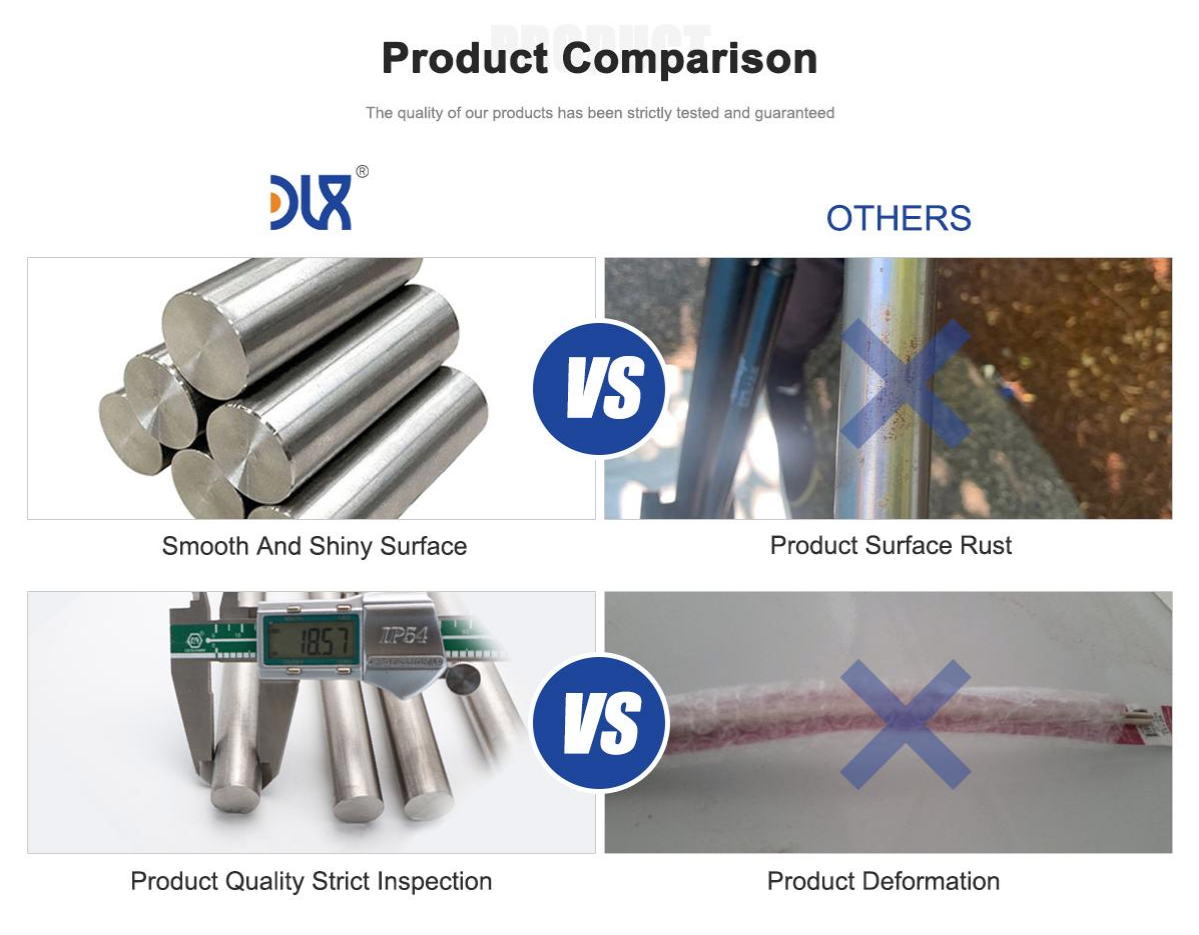

Sourcing the right alloy is only half the challenge; finding the right supplier is equally critical. DLX provides a full package of benefits that set us apart:

-

Consistent Quality: Every Hastelloy C-4 Bar is tested for composition, tensile strength, and corrosion resistance. We adhere to strict international standards.

-

Customization: DLX offers cut-to-size bars, precision machining, and tailored solutions to meet exact customer needs.

-

Global Logistics: With a strong distribution network, we ensure customers receive their orders on time, anywhere in the world.

-

Technical Expertise: Our engineers provide application guidance, welding support, and best-practice recommendations to help customers maximize performance.

-

Value Delivery: By balancing premium quality with competitive pricing, DLX ensures customers get the best return on their investment.

Comparison Table: Hastelloy C-4 vs Common Alloys

| Property | Hastelloy C-4 Bar | Stainless Steel 316L | Alloy 625 Bar |

|---|---|---|---|

| Base Material | Nickel-Chromium-Molybdenum | Iron-Nickel-Chromium | Nickel-Chromium-Molybdenum |

| Corrosion Resistance | Excellent in oxidizing environments | Good in mild conditions | Excellent, but less stable at high temps |

| Chloride Resistance | Superior resistance to pitting/crevice | Moderate | High |

| Temperature Performance | Up to ~1100°C | Up to ~870°C | Up to ~1093°C |

| Weldability | Excellent | Good | Excellent |

| Seawater Resistance | Long-term durability | Limited | Excellent |

| Structural Stability | Excellent under thermal cycling | Moderate | Good |

| Typical Applications | Chemical plants, marine, pollution control | Food, water, architecture | Aerospace, chemical processing |

| Cost Level | Higher | Lower | High |

Stainless steels such as 316L are often chosen for general use due to their availability and cost-effectiveness. However, in environments rich in chlorides or strong oxidizers, they corrode quickly. Alloy 625 offers strength and good corrosion resistance but is not as stable under prolonged high-temperature exposure as Hastelloy C-4.

C-4 bridges these gaps by offering both corrosion resistance and high-temperature structural stability. This makes it one of the most reliable choices when industries demand long-term durability under mixed conditions. DLX ensures that customers who choose C-4 receive material ready for the most demanding jobs.

Looking forward, demand for Hastelloy C-4 Bars will continue to rise as industries adapt to stricter standards and push for greater efficiency. DLX anticipates growth in:

-

Asia-Pacific chemical and marine industries where rapid development drives alloy demand.

-

European environmental sectors driven by regulatory compliance.

-

Middle Eastern desalination projects that rely on seawater-resistant alloys.

-

North American energy infrastructure where high-temperature resistant materials are critical.

DLX is strategically prepared to support this demand with a robust supply chain, extensive inventory, and customer-focused service.

Hastelloy C-4 Bar is a durable nickel-chromium-molybdenum alloy that provides unmatched reliability in high-temperature and corrosive environments. Its resistance to strong oxidizers, chlorides, and structural degradation makes it indispensable across industries ranging from chemical processing to marine engineering.

At DLX, we deliver more than just metal bars—we deliver assurance. Our commitment to quality, global reach, and technical support ensures that customers get exactly what they need, when they need it. As industrial demands grow more challenging, DLX Hastelloy C-4 Bar remains a dependable solution, helping companies achieve safer, more efficient, and more sustainable operations.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Q1: What is Hastelloy C-4 Bar made of?

A1: It is a nickel-chromium-molybdenum alloy designed for outstanding resistance to strong oxidizers and high-temperature corrosion.

Q2: What makes Hastelloy C-4 different from other Hastelloy grades?

A2: It offers excellent structural stability at high temperatures and resists grain-boundary precipitates that can weaken alloys during thermal cycling.

Q3: In which industries is Hastelloy C-4 Bar commonly used?

A3: It is widely used in chemical processing, waste treatment, marine engineering, and high-temperature gas scrubbers.

Q4: How does Hastelloy C-4 Bar perform in seawater environments?

A4: It provides superior resistance to pitting, crevice corrosion, and stress corrosion cracking even in aggressive chloride conditions.

Q5: Is Hastelloy C-4 Bar weldable and easy to fabricate?

A5: Yes, it has excellent weldability and can be fabricated with conventional methods while retaining its corrosion resistance.

Q6: What temperatures can Hastelloy C-4 Bar withstand?

A6: It performs well in high-temperature service, maintaining strength and stability up to approximately 1100°C.

Q7: Why is Hastelloy C-4 preferred over stainless steel in harsh chemical environments?

A7: Its resistance to strong oxidizers, chlorides, and elevated temperature conditions makes it far more durable than stainless steel.

Q8: Why should industries choose DLX for Hastelloy C-4 Bar supply?

A8: DLX ensures consistent quality, compliance with ASTM standards, customized dimensions, and reliable global delivery backed by technical expertise.