Corrosion-Resistant Incoloy 800 Strip for Petrochemical and Power Generation

Industrial processes today are pushing materials to their limits. Whether it’s in a power plant boiler, a petrochemical heat exchanger, or a refining furnace, the need for alloys that can withstand high temperatures while resisting chemical attack is more important than ever. Among the most trusted materials for such demanding environments is Incoloy 800 strip, a nickel-iron-chromium alloy designed to perform where traditional steels and alloys fall short.

Incoloy 800 strip is engineered for environments where both high heat and corrosive conditions are present. Its nickel-iron-chromium base composition provides a balanced set of properties, including:

High-temperature stability: Performs reliably up to about 1100°C (2010°F).

Corrosion resistance: Withstands oxidizing and carburizing atmospheres.

Structural integrity: Maintains mechanical properties during long-term thermal cycling.

Fabricability: Easily welded, cut, and formed with standard techniques.

Versatility: Suitable across multiple industries, from chemical to power generation.

This combination makes Incoloy 800 strip a dependable choice for projects requiring both strength and corrosion resistance.

For more details, pls directly contact us.

The petrochemical industry exposes materials to some of the harshest environments possible. High-pressure steam, hydrocarbons, acids, and aggressive process gases can quickly degrade standard alloys. Incoloy 800 strip is specifically designed to resist such challenges.

Typical applications include:

Heat exchanger components: Providing stable performance under corrosive process streams.

Process heaters: Maintaining structural strength under constant high heat.

Catalyst supports: Ensuring durability in reformer and cracking units.

Reactor internals: Withstanding corrosive feedstocks and chemical reactions.

Its corrosion resistance helps extend the service life of critical equipment, reducing downtime and lowering overall maintenance costs.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Power plants rely on alloys that can resist scaling, oxidation, and structural deformation in high-heat environments. Incoloy 800 strip plays a vital role in ensuring the efficiency and safety of these systems.

Key uses include:

Boiler tubes and supports: Providing resistance against scaling at high temperatures.

Superheater components: Maintaining mechanical stability under thermal cycling.

Heat recovery systems: Withstanding prolonged exposure to hot gases.

By delivering consistent performance, Incoloy 800 strip contributes to the reliability of energy production systems worldwide.

Industrial furnaces operate under carburizing and oxidizing atmospheres, environments that rapidly degrade conventional steels. Incoloy 800 strip’s excellent resistance to carburization makes it a preferred material for:

Furnace linings

Baffles and trays

Heating fixtures

Thermal treatment supports

These applications require alloys that can endure repeated cycling between extreme heat and cooling while retaining their structural integrity.

Comparison Table: Incoloy 800 vs 800HT vs 925 Strips

| Property | Incoloy 800 Strip | Incoloy 800HT Strip | Incoloy 925 Strip |

|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr with optimized Al + Ti | Ni-Fe-Cr with Mo, Cu, Ti |

| Service Temperature | Up to ~1100°C (2010°F) | Up to ~1150°C (2100°F) | Moderate high-temp, optimized for seawater |

| Creep Strength | Good | Superior | High |

| Oxidation Resistance | Excellent | Excellent | Excellent in seawater and chlorides |

| Carburization Resistance | Very good | Very good | Excellent under chloride and sour gas |

| Key Applications | Petrochemical, power generation, furnaces | High-temp industrial systems, refineries | Offshore, marine, chemical plants |

| Chloride Resistance | Limited | Limited | Excellent |

| Industry Focus | Petrochemical & energy | High-temperature performance | Offshore oil, gas, and marine systems |

Several key global trends are increasing demand for high-performance alloys like Incoloy 800 strip:

Rising energy consumption: More power plants worldwide require durable materials in boilers and heat exchangers.

Petrochemical growth: Expanding production of fuels, plastics, and chemicals is pushing the need for heat-resistant alloys.

Efficiency improvements: Industries are running equipment closer to operational limits, requiring materials with proven reliability.

Sustainability goals: Long-lasting alloys reduce waste, downtime, and energy losses.

Regulatory standards: Tougher safety and efficiency requirements demand high-performance solutions.

These drivers ensure that Incoloy 800 strip remains essential for industrial growth.

While Incoloy 800 strip offers outstanding performance, there are situations where other alloys might be selected.

Incoloy 800HT: Offers improved creep resistance for applications where components must endure long-term exposure at the highest temperatures.

Incoloy 925: Optimized for marine and offshore applications, providing superior resistance to chlorides and seawater corrosion.

For most petrochemical and power generation systems, however, Incoloy 800 provides the best balance between cost, performance, and availability.

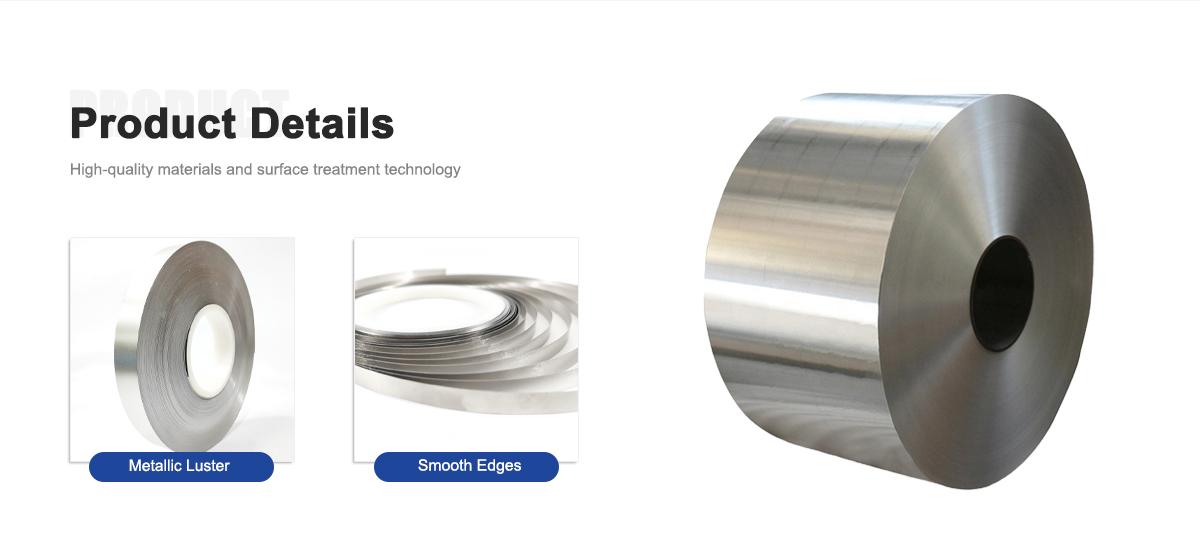

Customization and Supply

We understand that no two projects are the same. That’s why we offer Incoloy 800 strip in a wide variety of dimensions, finishes, and supply forms. Our capabilities include:

Thicknesses ranging from thin foils to heavy-duty strips.

Widths cut precisely to customer specifications.

Heat treatments to optimize mechanical and corrosion-resistant properties.

Surface finishes designed for both functional and aesthetic performance.

This flexibility ensures our Incoloy 800 strip integrates seamlessly into diverse projects.

Our strength lies not only in delivering high-quality alloys but also in the value-added services we provide to clients.

Technical expertise: Guidance on selecting the right grade and configuration.

Stringent quality control: Each batch undergoes rigorous testing for chemistry and mechanical properties.

Flexible customization: Dimensions, finishes, and tolerances are tailored to project needs.

Global logistics: Reliable supply chain and delivery, ensuring projects stay on schedule.

Long-term partnerships: We focus on building strong relationships, not just transactions.

By combining quality materials with reliable service, we ensure that our customers receive a product that meets both technical and operational expectations.

As global industries continue to expand, the reliance on high-performance alloys will only grow. Incoloy 800 strip is positioned as a key material in supporting this expansion, particularly as petrochemical demand rises and power generation seeks greater efficiency.

Our company is committed to meeting this demand by expanding production capabilities, investing in new technologies, and reinforcing our role as a trusted supplier of corrosion-resistant and high-temperature alloys.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Incoloy 800 strip suitable for petrochemical systems?

Its resistance to oxidation and carburization in high-temperature, corrosive environments.Can Incoloy 800 strip be used in power generation?

Yes, it is widely used in boilers, heat exchangers, and superheaters.What is the temperature limit of Incoloy 800 strip?

It performs reliably up to around 1100°C (2010°F).How does Incoloy 800 strip resist chemical attack?

It has a nickel-iron-chromium composition that resists oxidation, acids, and aggressive gases.Is Incoloy 800 strip weldable?

Yes, it can be welded and fabricated using conventional processes.What industries commonly use Incoloy 800 strip?

Petrochemical, refining, chemical processing, and power generation.How does Incoloy 800 compare with Incoloy 800HT?

800HT offers higher creep strength, while 800 provides cost-effective high-temp resistance.Can Incoloy 800 strip be customized for specific projects?

Yes, it can be supplied in different widths, thicknesses, and surface finishes.