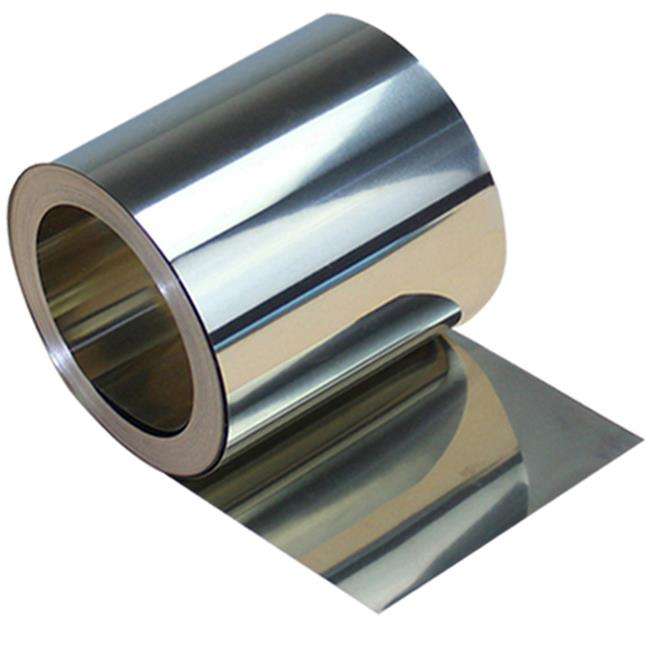

Superior Creep-Resistant Incoloy 800HT Strip for High-Temperature Industrial Systems

Industrial systems today are running hotter, longer, and under harsher conditions than ever before. From petrochemical reactors and heat exchangers to power plant superheaters and industrial furnaces, materials are constantly challenged to maintain strength and reliability. Incoloy 800H T strip has established itself as one of the most dependable solutions for such environments, thanks to its superior creep resistance and outstanding stability at elevated temperatures.

For more details, pls directly contact us.

Incoloy 800 HT is a nickel-iron-chromium alloy designed for applications requiring both resistance to corrosion and structural integrity at very high temperatures. It is essentially an enhanced version of Incoloy 800 and 800H, with carefully controlled levels of carbon, aluminum, and titanium that significantly improve its creep-rupture strength.

Key features of Incoloy 800HT strip include:

High creep resistance: Retains strength even during long-term exposure to extreme heat.

Thermal stability: Operates continuously up to 1150°C (2100°F).

Oxidation and carburization resistance: Protects equipment in aggressive atmospheres.

Fabrication flexibility: Weldable and formable with standard industrial methods.

Long service life: Reduces downtime and maintenance costs.

These properties make it a prime candidate for industries where equipment reliability directly impacts productivity and safety.

The demand for Incoloy 800HT strip is fueled by its unique ability to maintain mechanical stability under sustained high temperatures.

In refining and petrochemical plants, process equipment faces aggressive conditions that include both chemical corrosion and intense heat. Incoloy 800HT strip is used extensively in:

Heat exchanger plates

Reactor internals

Catalyst supports

Steam reformers

Its resistance to carburization allows it to withstand environments where hydrocarbon gases could otherwise weaken less durable materials.

Power plants require materials that remain strong even after years of service in high-temperature steam systems. Incoloy 800HT strip plays a vital role in:

Superheater tubing supports

Heat recovery steam generator components

Boiler internals

Structural furnace parts

By resisting creep deformation, Incoloy 800HT ensures safe and efficient power generation.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

High-temperature furnaces demand materials that can endure repeated heating and cooling cycles. Incoloy 800HT strip is commonly used for:

Furnace linings

Baffles and trays

Heating element supports

Thermal processing equipment

Its durability reduces failures caused by prolonged heat exposure, making it a reliable choice for long-term furnace operation.

Several global industrial trends are creating stronger demand for advanced alloys like Incoloy 800HT strip:

Higher operating temperatures: Energy and chemical plants are pushing processes closer to thermal limits to boost efficiency.

Longer equipment lifecycles: Reducing maintenance downtime is critical in competitive industries.

Stricter safety standards: Materials must meet higher reliability expectations in critical applications.

Global infrastructure expansion: Rapid growth in petrochemicals, energy, and heavy industry increases demand for creep-resistant alloys.

Shift to sustainability: Alloys with longer lifespans reduce waste and contribute to more sustainable industrial operations.

These trends position Incoloy 800HT strip as an essential material for the future of high-temperature systems.

Comparison with Incoloy 800 and 800H

While Incoloy 800 and 800H offer excellent high-temperature performance, Incoloy 800HT goes further by addressing the need for superior creep strength.

Incoloy 800: Provides reliable oxidation and corrosion resistance at elevated temperatures, suitable for general high-temperature use.

Incoloy 800H: Improves creep strength with higher carbon content, extending service life in more demanding conditions.

Incoloy 800HT: Offers the highest creep resistance and tightest control of alloy chemistry, making it the best choice for continuous high-heat exposure.

This progression highlights how Incoloy 800HT strip is the logical solution for industries requiring the most robust material in critical systems.

| Property | Incoloy 800 Strip | Incoloy 800H Strip | Incoloy 800HT Strip |

|---|---|---|---|

| Base Composition | Ni-Fe-Cr | Ni-Fe-Cr with higher C | Ni-Fe-Cr with controlled Al + Ti |

| Service Temperature | Up to ~1100°C (2010°F) | Up to ~1100°C (2010°F) | Up to ~1150°C (2100°F) |

| Creep Strength | Good | Better | Superior |

| Oxidation Resistance | Excellent | Excellent | Excellent |

| Carburization Resistance | Very good | Very good | Excellent |

| Mechanical Stability | Strong at high temps | Improved | Highest |

| Key Applications | Petrochemical, power generation, furnaces | High-temp boilers, heaters | Industrial furnaces, heat exchangers, reactors |

| Industry Focus | General high-temp use | Higher creep resistance needs | Long-term, extreme high-temp performance |

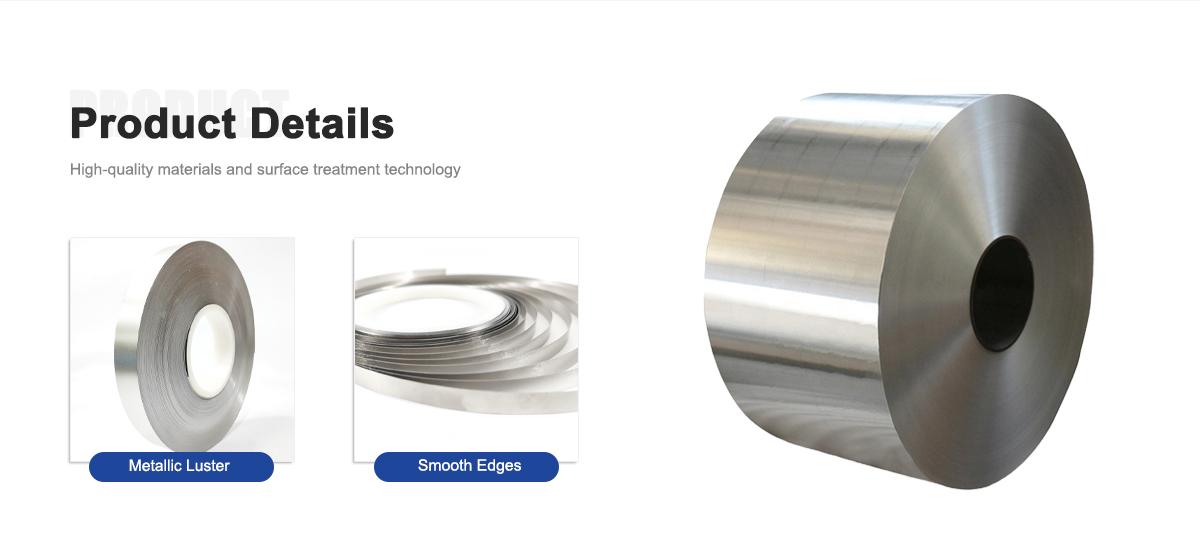

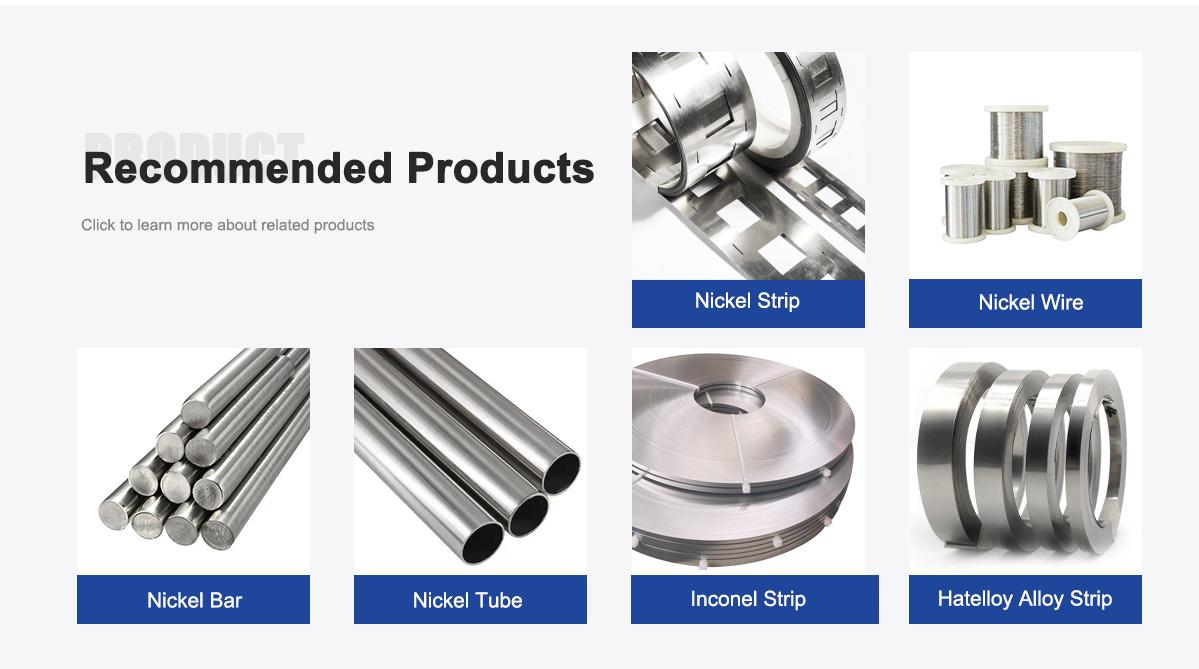

Every industrial system has its own requirements, which is why we offer tailor-made Incoloy 800HT strip solutions. Our capabilities include:

Wide range of thicknesses and widths.

Custom-cut strips to fit exact project specifications.

Heat-treated options for enhanced mechanical properties.

Multiple surface finishes for different operational environments.

Flexible order volumes, from prototype runs to large-scale supply.

This adaptability ensures our materials integrate seamlessly into both existing equipment and new builds.

What sets us apart is not only the quality of the alloys we deliver but also the comprehensive support we provide to our customers.

Technical consultation: We help clients select the right alloy grade for their specific application.

Quality assurance: Every batch undergoes stringent testing to confirm chemical composition and mechanical performance.

Reliable logistics: Global supply capabilities ensure timely delivery for critical projects.

Customization expertise: We tailor dimensions, finishes, and treatments to meet unique operational demands.

Long-term partnerships: Our goal is to support clients throughout the lifecycle of their projects, not just at the point of sale.

By focusing on reliability and service, we make sure our customers have the confidence to operate their systems at maximum efficiency.

As industries continue to push for higher efficiency and greater durability, the demand for creep-resistant alloys like Incoloy 800HT strip will only grow. Power plants are being designed for longer service cycles, petrochemical facilities are processing increasingly aggressive feedstocks, and industrial furnaces are running hotter and more frequently.

Our company is investing in expanded capacity and advanced processing technologies to meet this demand. By aligning with future industry needs, we ensure that our clients will always have access to the most reliable materials available.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes Incoloy 800HT strip superior to standard Incoloy 800?

Its higher creep-rupture strength at elevated temperatures.Can Incoloy 800HT strip handle long-term exposure to high heat?

Yes, it is designed for continuous service up to 1150°C (2100°F).What industries typically use Incoloy 800HT strip?

Petrochemical, refining, power generation, and heat treatment.Is Incoloy 800HT resistant to carburization?

Yes, it has excellent resistance to carburization and oxidation.Can Incoloy 800HT strip be welded and fabricated?

Yes, it is weldable using conventional techniques.How does Incoloy 800HT differ from Incoloy 800H?

800HT has tighter controls on carbon, aluminum, and titanium content, giving it higher creep strength.What are common applications for Incoloy 800HT strip?

Furnace parts, heat exchangers, chemical reactors, and superheaters.Can Incoloy 800HT strip be customized for industrial projects?

Yes, it can be supplied in custom widths, thicknesses, and surface finishes.