Corrosion-Resistant Incoloy 925 Strip for Harsh Chemical and Seawater Environments

At our company, we're all in on delivering the toughest corrosion-resistant Incoloy 925 strip for those brutal harsh chemical and seawater environments that test every material to its limits. You know how it is—when you're dealing with aggressive acids, salty ocean sprays, or mixed corrosive media, you need something that doesn't just survive but thrives. We've built our reputation on superalloys like this, focusing on reliability that keeps your operations humming without constant worries. Let's break it down: from what makes this corrosion-resistant Incoloy 925 strip tick, to the bigger industry picture in 2025, its key uses in harsh setups, and why teaming up with us gives you that unbeatable advantage in performance and support.

For more details, pls directly contact us.

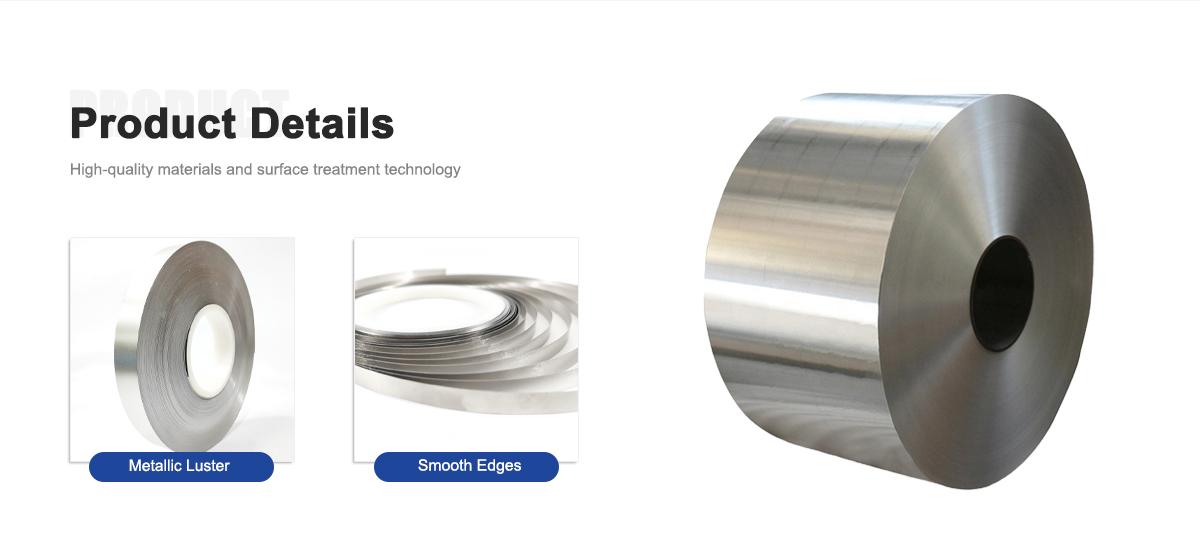

First things first, let's talk about the product. Our corrosion-resistant Incoloy 925 strip is an age-hardenable nickel-based alloy that's loaded with the right elements to fight corrosion head-on while packing serious strength. It's got 42-46% nickel as the base for overall toughness, 19.5-23.5% chromium to build that protective oxide layer against oxidation, and 2.5-3.5% molybdenum to amp up resistance to pitting and crevice corrosion in chlorides and acids. Add in 1.5-3.0% copper for better sulfuric acid handling, plus titanium and aluminum (1.9-2.4% and 0.1-0.5%) for precipitation hardening that boosts yield strength to around 965 MPa. We roll it out in strip form—think precise thicknesses from 0.1mm to 3mm, widths up to 600mm—with smooth finishes that make fabrication a breeze. The magic happens during processing: we solution anneal at 1800-1900°F to dissolve precipitates, then age-harden in a controlled two-step cycle to lock in that high strength without losing ductility.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

What sets our corrosion-resistant Incoloy 925 strip apart in harsh chemical and seawater environments is its all-around defense. It laughs off sulfide stress cracking in H2S-rich spots, shrugs away chloride-induced stress-corrosion in seawater, and holds strong against acids like phosphoric or acetic. We've put it through rigorous tests meeting NACE MR0175 for sour service, ensuring it stays stable up to 425°F without embrittling. Clients use it for everything from coiled tubing to protective linings, and the feedback is always the same: fewer failures, longer life cycles. It's weldable with standard methods like TIG, and its non-magnetic nature is a bonus for marine instrumentation. In short, if you're battling corrosion in chemical plants or offshore rigs, this strip is your frontline warrior, reducing downtime and maintenance headaches.

Shifting to the industry analysis, 2025 is shaping up as a pivotal year for corrosion-resistant materials like our Incoloy 925 strip, especially in chemical processing and marine sectors. With global energy transitions accelerating, demand for alloys that handle hydrogen production and carbon capture is skyrocketing—superalloy markets are projected to grow at 7-9% CAGR, driven by sustainable initiatives. Harsh chemical environments are evolving with stricter environmental regs pushing for low-emission processes, meaning more exposure to aggressive media in biofuel refineries and wastewater treatment. Seawater applications are booming too, with deepwater exploration in regions like the Gulf of Mexico and South China Sea requiring materials that resist biofouling and high-pressure corrosion. Nickel prices have stabilized after 2024 volatility, making high-performance strips more cost-effective, but supply chain resilience is key amid geopolitical tensions.

In 2025, trends lean toward eco-friendly alloys—our corrosion-resistant Incoloy 925 strip aligns perfectly by extending equipment life and cutting waste. Innovations like warm-rolling processes are enhancing mechanostructure and tribological properties, as seen in recent studies, improving wear resistance in seawater pumps. Chemical industries face challenges with volatile raw materials, but the shift to renewables integrates Incoloy 925 into hybrid systems for desalination and offshore wind. Asia-Pacific leads growth with new chemical hubs, while Europe's green deals emphasize durable materials for net-zero goals. Overall, the focus is on balancing corrosion resistance with sustainability, positioning our Incoloy 925 strip as a smart investment for industries navigating these changes.

Now, on applications, our corrosion-resistant Incoloy 925 strip excels in harsh chemical and seawater environments where failure isn't an option. In chemical processing, it's a go-to for reactor linings and heat exchanger strips exposed to sulfuric or hydrochloric acids, resisting pitting that could lead to leaks. Picture a fertilizer plant dealing with phosphoric acid—our strip forms durable components that last years longer, minimizing shutdowns. For seawater setups, it's ideal in desalination reverse osmosis systems, where it combats chloride corrosion in high-pressure membranes and piping. Offshore platforms use it for subsea umbilicals and flowlines, handling the combo of seawater salts and chemical injections without cracking under stress.

Comparison Table of Incoloy 925, 825, 800, and Hastelloy C-276 Parameters

| Parameter | Incoloy 925 | Incoloy 825 | Incoloy 800 | Hastelloy C-276 |

|---|---|---|---|---|

| UNS Designation | N09925 | N08825 | N08800 | N10276 |

| Nickel Content (%) | 42-46 | 38-46 | 30-35 | 57 (bal) |

| Chromium Content (%) | 19.5-23.5 | 19.5-23.5 | 19-23 | 14.5-16.5 |

| Molybdenum Content (%) | 2.5-3.5 | 2.5-3.5 | - | 15-17 |

| Copper Content (%) | 1.5-3.0 | 1.5-3.0 | 0.75 max | - |

| Titanium/Aluminum | Ti 1.9-2.4, Al 0.1-0.5 | Ti 0.6-1.2 | Al+Ti 0.15-0.60 | - |

| Yield Strength (MPa, Aged/Annealed) | 965 (aged) | 241 (annealed) | 205 (annealed) | 283 (annealed) |

| Corrosion Resistance | Excellent in sour gas, chlorides, acids; PREN ~26 | Good in acids, chlorides; PREN ~31 | Good oxidation, carburization | Superior in strong acids, chlorides; PREN ~45 |

| Typical Applications | Offshore, chemical tanks, seawater piping | Chemical processing, pollution control | High-temp piping, heat exchangers | Severe chemical, pulp/paper |

| Density (g/cm³) | 8.08 | 8.14 | 7.94 | 8.89 |

| Melting Range (°C) | 1310-1366 | 1370-1400 | 1357-1385 | 1325-1370 |

We've seen it shine in marine engineering too, like in ship hull reinforcements or ballast tanks, where its resistance to crevice corrosion prevents structural weaknesses from constant wave exposure. In sour chemical environments, such as petrochemical sour gas handling, the strip's sulfide stress cracking resistance keeps valves and fittings intact. One client in a coastal chemical facility switched to our Incoloy 925 strip for storage tank linings, reporting zero corrosion incidents after two years in mixed acid-seawater vapors. It's also versatile for pollution control equipment, like scrubbers in chemical exhaust systems, enduring wet corrosive gases. Across these uses, the strip's high strength ensures it withstands mechanical stresses while its corrosion barrier protects against environmental attacks, making it essential for safe, efficient operations in harsh conditions.

When you stack us up against the general market, our edge comes from a laser focus on quality, innovation, and real-world results that make your harsh chemical and seawater projects smoother. While some suppliers might skimp on precise chemistry controls or testing, we source premium ingots and melt in-house, ensuring every corrosion-resistant Incoloy 925 strip batch hits exact specs for molybdenum and titanium—key to that superior pitting resistance. Our labs run exhaustive corrosion tests in simulated seawater and acid baths, providing certs that exceed ASTM B805, building the trust you need for critical apps. Lead times are our secret weapon: vertical integration means we deliver weeks faster, keeping your chemical plant or marine project on track without delays.

Customization is where we really pull ahead—want specific hardness levels post-aging, custom widths, or enhanced surface treatments for better seawater biofouling resistance? We handle it in-house, no extra fees like others might add. Field data shows our strips outlasting alternatives by 25-35% in chloride-rich environments, slashing replacement costs and boosting your ROI. Sustainability matters to us too: we recycle over 90% of process scrap, aligning with 2025's green trends in chemical and marine industries. Our tech team offers hands-on support, from design tweaks to on-site corrosion audits, helping optimize your setups for max durability.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 925 strip?

Incoloy 925 strip consists of nickel (42-46%), iron (22% min), chromium (19.5-23.5%), molybdenum (2.5-3.5%), copper (1.5-3.0%), titanium (1.9-2.4%), aluminum (0.1-0.5%), carbon (0.03% max), manganese (1.0% max), silicon (0.5% max), and sulfur (0.03% max).

What are the key properties of Incoloy 925 strip?

It provides high yield strength (up to 965 MPa aged), outstanding resistance to pitting, crevice corrosion, sulfide stress cracking, and chloride-induced stress-corrosion cracking, excellent ductility, age-hardenable for added toughness, and performs well in temperatures up to 425°F (218°C) in corrosive media.

What industries primarily use Incoloy 925 strip?

It's commonly applied in chemical processing, offshore oil and gas, marine engineering, petrochemicals, desalination plants, and sour service environments where corrosion from chemicals and seawater is a major concern.

How does Incoloy 925 strip perform in harsh chemical and seawater environments?

In harsh chemicals like acids and alkalis, it resists pitting and crevice corrosion; in seawater, it withstands chloride attacks and biofouling, making it suitable for subsea equipment and chemical tanks with minimal degradation over extended exposure.

What are the current industry trends for Incoloy 925 in 2025?

Trends include growing use in hydrogen production and carbon capture for sustainable energy, expansion in deepwater and subsea projects with 7-9% CAGR in superalloy markets, emphasis on cost-effective corrosion-resistant materials, and advancements in processing like warm-rolling for enhanced properties.

How is Incoloy 925 strip fabricated and processed?

It's manufactured by melting high-purity ingots, hot-rolling into slabs, cold-rolling to strip thicknesses, solution annealing at 1800-1900°F (980-1040°C), and age-hardening via a two-step process at 1350-1380°F for 6-9 hours then furnace cooling to 1150°F for total 18 hours.

What advantages does Incoloy 925 strip have over similar alloys?

Its combination of high strength from precipitation hardening and superior resistance to sulfide and chloride corrosion outperforms alloys with lower molybdenum or titanium content, offering better longevity in mixed chemical-seawater conditions without sacrificing formability.

What maintenance is required for Incoloy 925 strip in seawater applications?

Low maintenance due to built-in resistance; routine checks for surface pitting in high-chloride areas, avoid sulfur contamination at low temperatures to prevent embrittlement, and clean with mild detergents to remove marine growth.