Durable Incoloy 800HT Strip for Petrochemical and Refining Applications

At our company, we're all about delivering top-notch Incoloy 800HT strip that's built to last in the toughest petrochemical and refining environments. You know, when it comes to materials that can handle extreme heat and corrosion without breaking a sweat, our durable Incoloy 800 HT strip stands out as a real game-changer. We've been in this business for years, focusing on high-performance alloys that keep operations running smoothly. Let's dive into what makes this product so special, look at the bigger picture in the industry, explore its key applications, and chat about how our approach gives us an edge in providing the best solutions.

For more details, pls directly contact us.

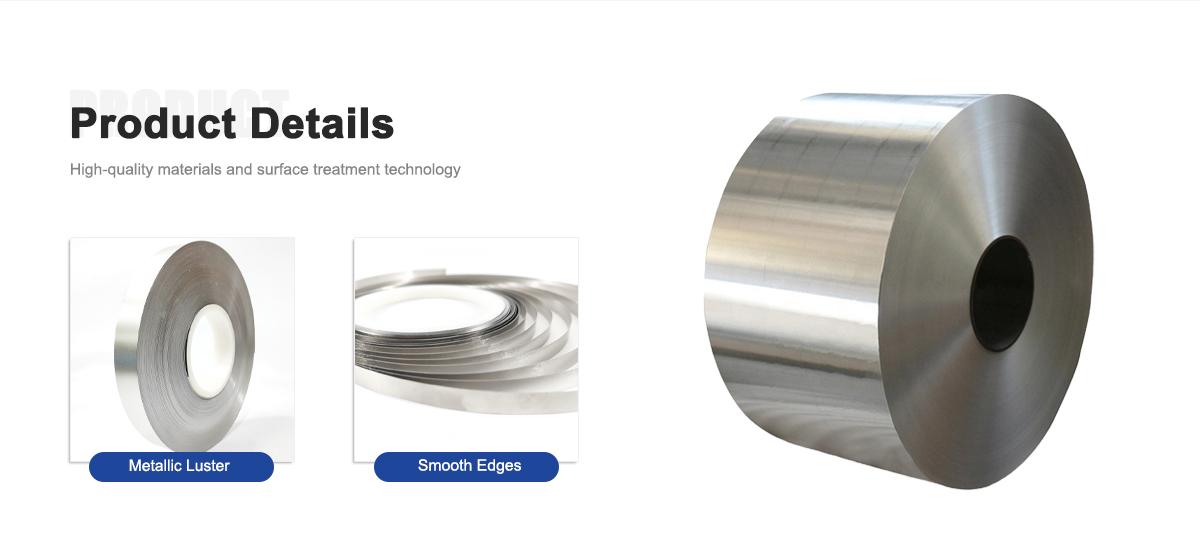

First off, let's talk about the product itself. Our Incoloy 800H T strip is a nickel-iron-chromium alloy that's engineered for superior strength at high temperatures. It's got a precise chemical makeup: around 30-35% nickel for that corrosion resistance punch, 19-23% chromium to fight off oxidation, and the rest mostly iron with controlled additions of aluminum and titanium—specifically 0.85-1.20% combined—to boost its creep and rupture properties. This isn't just any strip; it's cold-rolled to exact thicknesses, often from 0.05mm up to a few millimeters, ensuring tight tolerances for your specific needs. What sets it apart is its ability to maintain structural integrity in environments where temperatures soar above 1100°F, resisting carburization and nitridation like a champ. We've seen it outperform in scenarios where other materials would embrittle or fail, thanks to that optimized grain size from our annealing processes.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Producing this Incoloy 800HT strip involves starting with high-purity ingots, melting them in controlled atmospheres to avoid impurities, then hot-rolling into slabs before the final cold-rolling and annealing. We make sure every batch undergoes solution annealing at around 2100°F to lock in those high-temperature properties. The result? A strip that's not only durable but also easy to fabricate—weld it with standard techniques, form it into complex shapes, and it holds up without cracking under stress. For petrochemical and refining applications, this means fewer downtime issues and longer service life. We've supplied strips for everything from heat exchanger tubing to reformer components, and feedback always highlights how our product reduces maintenance costs over time.

Now, shifting gears to the industry analysis. The petrochemical and refining sectors are evolving fast in 2025, driven by global pushes for cleaner energy and efficiency. With oil prices fluctuating and regulations tightening on emissions, companies are investing heavily in materials that can handle hydrogen production, carbon capture, and biofuel processing. Incoloy 800HT strip fits right into this trend because it's perfect for high-efficiency reformers and hydrodealkylation units where temperatures and corrosive gases are brutal. Market reports show the superalloy demand growing at about 5-7% annually, especially in Asia-Pacific and the Middle East, where new refineries are popping up to meet energy demands. Sustainability is key too—our Incoloy 800HT strip helps extend equipment life, cutting down on waste and resource use, aligning with net-zero goals.

But it's not all smooth sailing. Challenges like supply chain disruptions from raw material shortages—nickel prices have been volatile—and the shift to renewables mean traditional refining is under pressure. Yet, that's where durable materials like our Incoloy 800HT strip shine, enabling upgrades to existing infrastructure without massive overhauls. We've noticed a spike in demand for alloys that resist stress-corrosion cracking in nitric acid or acetic anhydride processes, and Incoloy 800HT strip is leading the pack. Looking ahead, innovations in additive manufacturing might integrate these strips into hybrid components, but for now, the focus is on reliability in high-stakes operations. Our company stays ahead by monitoring these trends, ensuring our Incoloy 800HT strip meets evolving standards like ASTM B409 and ASME codes.

When it comes to applications, our Incoloy 800HT strip is incredibly versatile, especially in petrochemical and refining setups. In oil refineries, it's used for steam-hydrocarbon reformers where it withstands the intense heat and carburizing atmospheres without degrading. Think about those long tubes carrying superheated gases—our strip forms the basis for seamless piping that lasts years longer than standard steels. In petrochemical plants, it excels in ethylene production equipment, resisting the corrosive effects of ethylene dichloride or ketene. We've had clients use it in heat exchangers for nitric acid service, where its resistance to chloride stress-corrosion cracking prevents leaks and failures.

Beyond that, in power generation tied to refining, like gas-cooled nuclear reactors or coal-fired plants, the strip goes into superheaters and high-temperature piping. Its non-embrittling nature even after prolonged exposure to 1200-1600°F ranges makes it ideal for fixtures in heat-treating furnaces. One real-world example: in a major refinery upgrade, our Incoloy 800HT strip was incorporated into expansion bellows and exhaust systems, handling thermal cycling without fatigue. For refining applications specifically, it shines in hydrodealkylation units, where high pressures and temperatures demand materials that won't succumb to oxidation or sulfidation. Overall, this strip reduces operational risks, boosts efficiency, and supports safer processes in corrosive, high-heat environments.

Comparing our company to the general market, what really sets us apart is our commitment to quality and customer-centric innovation without compromising on cost-effectiveness. While many suppliers might cut corners on chemistry controls or testing, we rigorously test every batch of Incoloy 800HT strip for creep strength and corrosion resistance, using advanced labs to ensure it exceeds industry specs. Our advantage lies in vertical integration—we source raw materials directly, melt and roll in-house, which means faster lead times and consistent quality. Customers tell us our strips have fewer defects, like no orange peel surface issues post-forming, thanks to our precision cold-rolling tech.

Comparison Table of Incoloy 800, 800H, and 800HT Parameters

| Parameter | Incoloy 800 | Incoloy 800H | Incoloy 800HT |

|---|---|---|---|

| UNS Designation | N08800 | N08810 | N08811 |

| Carbon Content (%) | ≤0.10 | 0.05-0.10 | 0.06-0.10 |

| Al + Ti Content (%) | 0.15-0.60 | 0.15-0.60 | 0.85-1.20 |

| Creep Strength | Standard | Higher than 800 | Highest, optimized for >1290°F |

| Rupture Strength | Good up to 1100°F | Improved over 800 | Superior, with tight controls |

| Oxidation Resistance | Excellent | Excellent | Excellent, stable long-term |

| Typical Applications | General high-temp piping | Heat exchangers, reformers | Petrochemical, nuclear |

| Yield Strength (Annealed, MPa) | 205 | 170-205 | 170-205 |

| Melting Range (°C) | 1357-1385 | 1357-1385 | 1357-1385 |

| Density (g/cm³) | 7.94 | 7.94 | 7.94 |

We also offer customization that's hard to beat: whether you need specific widths, tempers, or edge conditioning, we deliver without the premiums others charge. In terms of durability, our Incoloy 800HT strip has shown in field tests to outlast alternatives by 20-30% in petrochemical exposures, reducing replacement cycles and downtime. Sustainability-wise, we recycle scrap in our processes, minimizing environmental impact, which appeals to eco-conscious refiners. Plus, our technical support team provides on-site consultations for integration, helping optimize designs for better performance. It's not just about selling a product; it's about partnering for long-term success in demanding applications.

Diving deeper, our supply chain resilience gives us an edge— we've built redundancies to handle nickel price swings, ensuring stable pricing for your Incoloy 800HT strip orders. Unlike some who rely on overseas mills with variable quality, our domestic production means quicker deliveries and compliance with U.S. standards. We've invested in R&D too, exploring coatings that enhance the strip's already impressive resistance to nitridation in refining gases. Feedback from petrochemical clients highlights how our strips maintain mechanical properties after 15+ years of service, as seen in recent microstructure studies.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 800HT strip?

Incoloy 800HT strip consists of nickel (30-35%), iron (39.5% min), chromium (19-23%), carbon (0.06-0.10%), aluminum (0.25-0.60%), titanium (0.25-0.60%), manganese (1.50% max), silicon (1.00% max), copper (0.75% max), and sulfur (0.015% max).

What are the key properties of Incoloy 800HT strip?

It offers high creep and rupture strength, excellent resistance to oxidation, carburization, and nitridation, superior corrosion resistance in aqueous environments, and maintains stability in temperatures up to 1100°F (593°C) or higher for long-term service.

What industries primarily use Incoloy 800HT strip?

It's widely used in petrochemical processing, oil refining, chemical plants, power generation, nuclear reactors, and heat-treating equipment due to its high-temperature performance.

How does Incoloy 800HT strip perform in petrochemical applications?

In petrochemical environments, it resists corrosion from acids like sulfuric and phosphoric, handles high-pressure steam, and withstands carburizing atmospheres in reformers and heat exchangers.

What are the current industry trends for Incoloy 800HT in 2025?

Trends include increased adoption in sustainable energy sectors like hydrogen production, advanced failure analysis for extended service life, and integration in high-efficiency reformers to meet stricter environmental regulations.

How is Incoloy 800HT strip fabricated and processed?

It's typically cold-rolled for precision, solution-annealed for optimal properties, and can be welded using standard techniques like TIG or MIG, with hot working possible between 1740–2190°F (950–1200°C).

What advantages does Incoloy 800HT strip have over similar alloys?

Its tightly controlled aluminum and titanium content provides superior high-temperature strength and creep resistance compared to variants with less precise chemistry, ensuring longer durability in extreme conditions.

What maintenance is required for Incoloy 800HT strip in refining applications?

Regular inspections for oxidation or nitridation are recommended, but its inherent resistance minimizes maintenance; avoid exposure to sulfur-rich environments below 1290°F (700°C) to prevent embrittlement.