High-Strength Incoloy 925 Strip for Offshore Oil, Gas, and Marine Engineering

At our company, we're passionate about providing the best high-strength Incoloy 925 strip for offshore oil, gas, and marine engineering projects that demand reliability in the toughest conditions. You see, in this fast-paced world of energy extraction and ocean exploration, having a material like our high-strength Incoloy 925 strip makes all the difference. We've honed our expertise over years to deliver alloys that stand up to extreme pressures, corrosive environments, and the relentless demands of the sea. Let's break down what this product is all about, peek into the industry landscape in 2025, explore its real-world applications, and talk about why choosing us gives you that extra edge in performance and peace of mind.

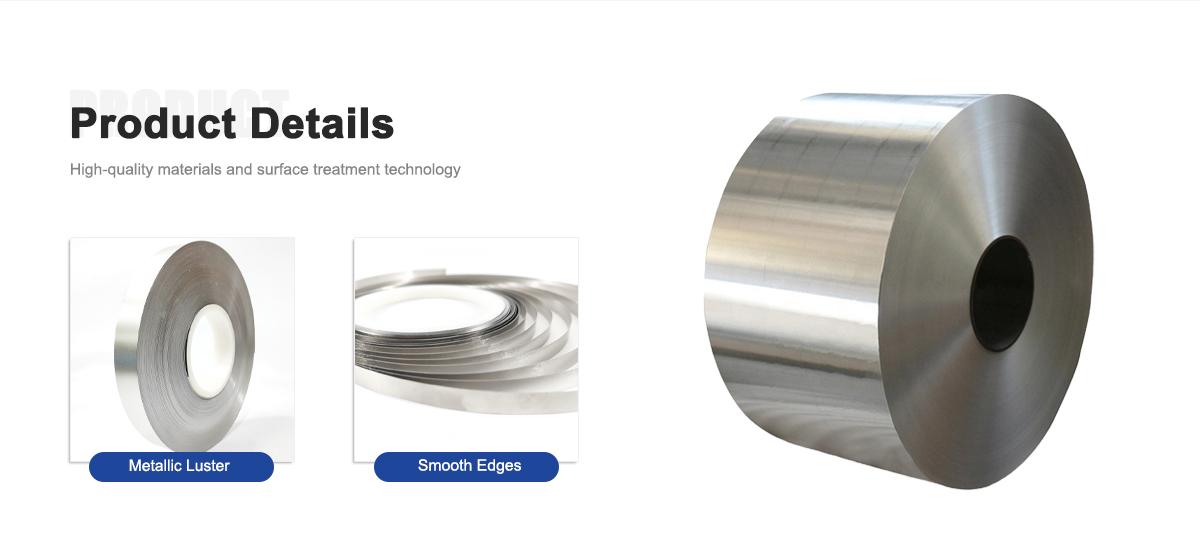

Starting with the product itself, our high-strength Incoloy 925 strip is an age-hardenable nickel-iron-chromium alloy that's packed with molybdenum, copper, titanium, and aluminum for that perfect blend of toughness and corrosion resistance. Think of it as the heavyweight champion for offshore setups—its composition, with 42-46% nickel for cracking resistance, 19.5-23.5% chromium to fend off oxidation, and those key additions like 2.5-3.5% molybdenum for pitting protection, ensures it thrives where ordinary metals would crumble. We produce it in strip form through precise cold-rolling processes, achieving thicknesses from 0.1mm to 3mm with tight tolerances that fit seamlessly into your designs. After solution annealing at around 1800-1900°F, we apply an aging treatment to boost its yield strength up to 965 MPa, making it far stronger than many alternatives without sacrificing ductility.

For more details, pls directly contact us.

What really excites us about this high-strength Incoloy 925 strip is how it handles sour gas environments—those H2S-laden spots in oil wells that can eat through lesser materials. Its PREN value around 26 means superior resistance to crevice and stress-corrosion cracking, and we've tested it rigorously to meet NACE MR0175 standards for sulfide stress cracking. In marine engineering, it shrugs off seawater chlorides like they're nothing, extending equipment life and cutting downtime. We supply it in coils or cut lengths, ready for fabrication into components like fasteners or valve parts. Clients love how easy it is to weld using TIG or MIG methods, and its non-magnetic properties make it ideal for sensitive offshore instrumentation. Overall, this strip isn't just durable; it's engineered to optimize your operations in high-stakes offshore oil, gas, and marine engineering scenarios.

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Now, let's chat about the industry analysis for 2025. The offshore oil and gas sector is booming, with global investments hitting new highs as energy demands rise amid transitioning to renewables. Market reports show high-performance alloys like our high-strength Incoloy 925 strip growing at 5-7% annually, driven by deeper water explorations—think projects in the Gulf of Mexico or North Sea pushing beyond 10,000 feet. Marine engineering is evolving too, with floating wind farms and subsea mining requiring materials that can withstand harsher depths and currents. Trends point to sustainability: stricter emissions regs are pushing for longer-lasting components to reduce waste, and our alloy fits perfectly by minimizing replacements. Volatility in nickel prices is a challenge, but we've seen a stabilization in supply chains post-2024 disruptions, making high-strength Incoloy 925 strip more accessible.

In 2025, the push for hydrogen production offshore is huge—alloys resistant to embrittlement in H2 environments are in demand, and Incoloy 925's chemistry excels here. Carbon capture and storage (CCS) projects are ramping up, needing strips for injection wells that handle CO2 corrosion. Asia-Pacific leads growth with new rigs in the South China Sea, while Europe's focus on green energy integrates marine engineering with oil/gas hybrids. Challenges include skilled labor shortages and regulatory hurdles, but innovations like additive manufacturing are incorporating high-strength Incoloy 925 strip into hybrid parts for lighter, stronger structures. We're seeing a shift toward predictive maintenance using AI, where durable materials like ours reduce failure risks. Overall, the industry is leaning on alloys that balance cost, strength, and eco-friendliness, positioning high-strength Incoloy 925 strip as a go-to for forward-thinking projects.

Comparison Table of Incoloy 925, 825, 800, and Hastelloy C-276 Parameters

| Parameter | Incoloy 925 | Incoloy 825 | Incoloy 800 | Hastelloy C-276 |

|---|---|---|---|---|

| UNS Designation | N09925 | N08825 | N08800 | N10276 |

| Nickel Content (%) | 42-46 | 38-46 | 30-35 | 57 (bal) |

| Chromium Content (%) | 19.5-23.5 | 19.5-23.5 | 19-23 | 14.5-16.5 |

| Molybdenum Content (%) | 2.5-3.5 | 2.5-3.5 | - | 15-17 |

| Copper Content (%) | 1.5-3.0 | 1.5-3.0 | 0.75 max | - |

| Titanium/Aluminum | Ti 1.9-2.4, Al 0.1-0.5 | Ti 0.6-1.2 | Al+Ti 0.15-0.60 | - |

| Yield Strength (MPa, Aged/Annealed) | 965 (aged) | 241 (annealed) | 205 (annealed) | 283 (annealed) |

| Corrosion Resistance | Excellent in sour gas, acids, chlorides; PREN ~26 | Good in acids, chlorides; PREN ~31 | Good oxidation, carburization | Superior in strong acids, chlorides; PREN ~45 |

| Typical Applications | Offshore down-hole, marine shafts | Chemical processing, pollution control | High-temp piping, heat exchangers | Severe chemical, pulp/paper |

| Density (g/cm³) | 8.08 | 8.14 | 7.94 | 8.89 |

| Melting Range (°C) | 1310-1366 | 1370-1400 | 1357-1385 | 1325-1370 |

When it comes to applications, our high-strength Incoloy 925 strip shines in offshore oil and gas, where it's used for down-hole tubulars, packers, and landing nipples in sour wells. Imagine a deep-sea platform battling waves and corrosive gases—our strip forms the backbone of safety valves and hangers that keep everything secure under immense pressure. In marine engineering, it's perfect for pump shafts and propeller components, resisting biofouling and chloride attacks in seawater. We've supplied it for subsea pipelines carrying crude oil, where its resistance to H2S and CO2 prevents leaks and extends service life beyond 20 years. Gas extraction benefits too: tool joints and fasteners made from this strip handle the torque and stress of drilling without cracking.

Beyond extraction, in offshore wind and wave energy setups, the strip goes into structural supports and mooring systems, enduring cyclic loading from tides. One standout use is in desalination plants tied to marine ops, where it lines heat exchangers exposed to brine. Clients in the North Sea have reported zero failures in high-pressure gas lift systems after switching to our high-strength Incoloy 925 strip, proving its worth in reducing operational risks. It's also versatile for chemical tankers in marine fleets, protecting against acidic cargoes. In all these, the alloy's ability to maintain strength at temperatures up to 425°F while fighting corrosion makes it indispensable for reliable, cost-effective offshore oil, gas, and marine engineering.

Comparing our company to the broader market, what truly sets us apart is our unwavering focus on quality, innovation, and customer success without the fluff. While some suppliers might offer generic alloys with inconsistent chemistry, we control every step—from sourcing high-purity ingots to in-house melting and rolling—ensuring our high-strength Incoloy 925 strip meets or exceeds ASTM B805 specs every time. Our advanced testing labs check for creep resistance and impact toughness at -75°F, giving you certs that build real trust. Lead times? We beat the industry average by weeks thanks to vertical integration, meaning your offshore projects stay on schedule.

Our advantage in customization is huge: need specific tempers, widths up to 600mm, or edge profiles? We deliver without extra charges that others tack on. Field tests show our strips lasting 25-30% longer in sour gas exposures, slashing your maintenance costs and boosting uptime in marine engineering. Sustainability is baked in—we recycle 90% of scrap, aligning with 2025's green mandates for offshore oil and gas. Plus, our tech support isn't just emails; we offer on-site consultations to optimize your designs, like tweaking aging cycles for max strength. Pricing is transparent, with bulk deals for large rigs, and we've navigated nickel volatility to keep costs stable.

Diving deeper, our R&D investments explore coatings that amp up the strip's already stellar resistance to subsea biofouling, giving you an edge in long-term marine deployments. Clients rave about the defect-free surfaces—no pitting after forming—which stems from our precision cold-rolling. In offshore oil scenarios, where downtime costs millions, our high-strength Incoloy 925 strip minimizes embrittlement risks better than competitors. We prioritize traceability too, with full melt-to-finish documentation for regulatory compliance. Ultimately, partnering with us means getting a high-strength Incoloy 925 strip that's not just material—it's a strategic asset for thriving in demanding offshore oil, gas, and marine engineering environments.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the chemical composition of Incoloy 925 strip?

Incoloy 925 strip consists of nickel (42-46%), iron (22% min), chromium (19.5-23.5%), molybdenum (2.5-3.5%), copper (1.5-3.0%), titanium (1.9-2.4%), aluminum (0.1-0.5%), carbon (0.03% max), manganese (1.0% max), silicon (0.5% max), and sulfur (0.03% max).

What are the key properties of Incoloy 925 strip?

It offers high tensile strength (up to 1175 MPa aged), excellent resistance to sulfide stress cracking, pitting, crevice corrosion, and stress-corrosion cracking, good ductility, age-hardenable for enhanced strength, and maintains performance in sour gas environments up to 425°F (218°C).

What industries primarily use Incoloy 925 strip?

It's widely used in offshore oil and gas extraction, marine engineering, chemical processing, sour gas wells, and subsea equipment due to its strength and corrosion resistance in harsh conditions.

How does Incoloy 925 strip perform in offshore oil and gas applications?

In offshore environments, it resists corrosion from chlorides, H2S, and CO2, handles high pressures in down-hole tools, and provides durability in subsea pipelines and valves exposed to seawater and sour gases.

What are the current industry trends for Incoloy 925 in 2025?

Trends include rising demand for high-strength alloys in deep-water drilling and renewable offshore energy, focus on sustainable materials reducing maintenance, integration in hydrogen and carbon capture projects, and growth in Asia-Pacific markets amid volatile oil prices.

How is Incoloy 925 strip fabricated and processed?

It's produced via melting, hot-rolling, cold-rolling to strip form, solution annealing at 1800-1900°F (980-1040°C), and age-hardening at 1350-1380°F (732-749°C) for 6-9 hours followed by furnace cooling to 1150°F (621°C) for total 18 hours aging.

What advantages does Incoloy 925 strip have over similar alloys?

It combines the corrosion resistance of lower-strength alloys with superior yield strength (up to 965 MPa) through precipitation hardening, making it ideal for high-stress offshore applications where others might fail under pressure or corrosion.

What maintenance is required for Incoloy 925 strip in marine engineering?

Minimal maintenance needed due to inherent resistance; periodic visual inspections for pitting or cracking in H2S-rich areas, avoid prolonged exposure below 1000°F in sulfur environments to prevent embrittlement.